Available models include KR18 and KR24—compact, mobile machines engineered for on-site production of standing seam roof panels from galvanized steel sheets with thicknesses between 0.4 and 0.8 mm.

These models are perfect for 20 to 26 gauge materials, ensuring watertight performance with concealed clip systems. The equipment is designed to continuously produce panels of any length directly at the installation site.

Lightweight and portable, the machines are well-suited for low-slope roofing applications in both commercial and industrial settings.

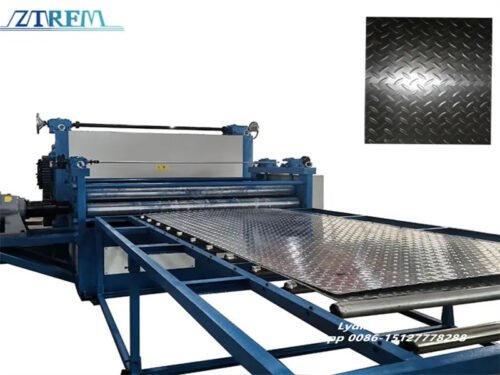

The KR24 steel sheet is a specialized profile and roof system designed as an SSR (Standing Seam Roof) with concealed fixing clips. Its innovative design eliminates the need to drill holes for installation, which helps reduce the risk of leaks. This lightweight, profiled sheet offers easy transportation and installation on site. It can be manufactured directly at the construction location, tailored precisely to the desired length, and is usually produced as a single piece running seamlessly from gutter to ridge. The KR24 corrugated sheet is especially suitable for buildings with low-slope roofs, accommodating gradients as low as 2%.

The KR24 profile represents a popular choice in roll forming applications, particularly in roofing and cladding. The term “KR” in KR24 stands for “Klip-Rib,” referring to its distinct ribbed design that provides enhanced strength and rigidity.

Typically crafted from galvanized steel or similar metals, the KR24 profile features a trapezoidal cross-section with multiple ribs extending along its length. These ribs contribute to excellent drainage and resistance to wind uplift, while dimensions can vary depending on specific customer requirements and manufacturers.

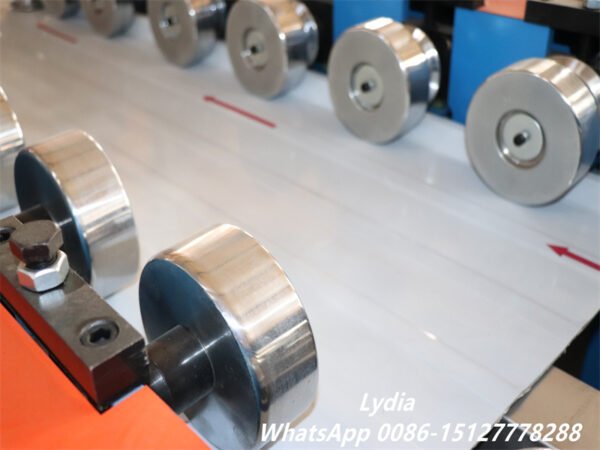

To produce the KR24 profile, a metal strip is fed into a roll forming machine that uses a series of rollers and forming stations to gradually shape the metal into the desired profile, complete with ribs and any necessary notches or cutouts. Once formed, the sheet is cut to the required length and prepared for transport and on-site installation.

The Technical Specifications Of The Kr24 Standing Seam Metal Roofing Machine:

| Parameter | Specification |

| Model | KR24 |

| Material Width | 610 mm Input / 457 mm Effective |

| Coil Thickness | 0.4–0.8 mm (aluminum coil) |

| Forming Speed | 0–15 m/min |

| Forming Stations | 9 hardened chromium rollers |

| Roller Diameter | 90 mm |

| Roller Material | Cr12Mov steel, quenched to HRC 58–62° |

| Shaft Material | High-grade forged 45# steel |

| Frame | Welded with “36#” I-steel |

| Decoiler Options | Manual or hydraulic |

| Cutting System | Hydraulic stop or tracking cut |

| Cutting Blade | Cr12, quenched to HRC 60–62° |

| Main Motor Power | 7.5 kW |

| Voltage | 380 V/50 Hz/3-phase (or customized) |

| Approx. Dimensions | 4500 × 950 × 1800 mm |

| Total Weight | ~3 tons |

| Transmission | Chain, gearbox, or universal joints |

Reviews

There are no reviews yet.