This hydraulic arch cambering machine is designed to create precise, subtle curves in roofing panels for specific applications. By forming these curved panels, it significantly reduces the need for roof purlins and steel supports, offering a cost-effective solution for roofing materials. Additionally, the arched roofs produced are not only robust and long-lasting but also aesthetically pleasing and modern in appearance.

A curved metal roof is a structural design that merges innovation with functionality, and it is increasingly utilized in industrial, commercial, and public buildings. This article will examine the fundamental concepts, types, production methods, and material recommendations for curved metal roofs.

Curved Metal Roof Overview

A curved metal roof, often referred to as a radius roof, features a distinct arched profile that adds a sleek and modern aesthetic. This architectural style has gained increasing popularity, especially in residential roofing, due to its visually appealing, contemporary design.

Curved metal roofing systems can be installed over both solid decking and open framing, providing versatile installation options. In homes, they are frequently used as decorative elements, such as coverings for bay windows, porches, or entryways, adding architectural character and visual interest.

Beyond residential use, curved metal roofs are also prevalent in commercial and public buildings, including churches, airports, arenas, convention centers, and various retail facilities, where their unique form enhances both appearance and functionality.

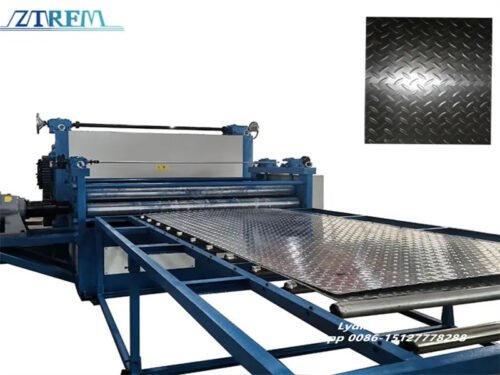

| Technical parameters of Curving machine | |||

|

|

|||

| Series | Details | Parameter | |

| Product sheet | Raw material | GI/PPGI | |

| Material thickness | 0.18-0.8mm (0.18-0.3 hard material HRB65) (0.3-0.7 soft material) | ||

|

Roll forming machine |

Feeding device | the platform width is adjustable by hand wheel, have the bearing inside to protect the edge of the steel sheet. | |

|

Rolling shaft |

Shaft Material: 45# STEEL | ||

| Shaft diameter: 70 mm | |||

| Tampering treatment, prevent deformed and improve the hardness | |||

|

Roller |

Roller material: 45# steel | ||

| Chromed treatment (Cr thickness:0.05 mm), anti-corrosion,Increase hardness, ensure the precision and good abrasion performance | |||

| Rolling station | 3 stations | ||

| To feed the steel sheet to pressing system | |||

| Machine structure | Middle plate welded structure | ||

| machine basic frame | 350# H steel welded with diagonal bracing inside | ||

| Bearing | Chinese famous brand Harbin | ||

| Work power | 3 kw | ||

| Roller spacer & Pull rod | Anti rusty treatment | ||

Reviews

There are no reviews yet.