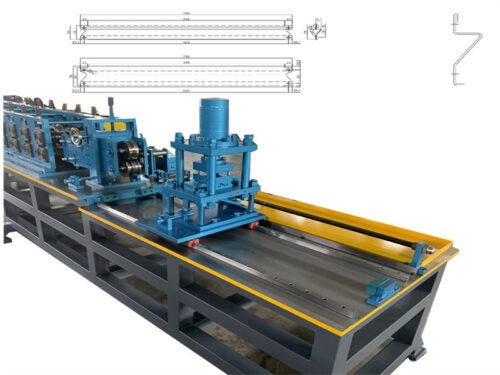

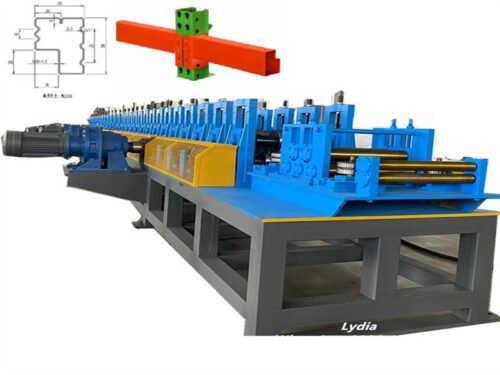

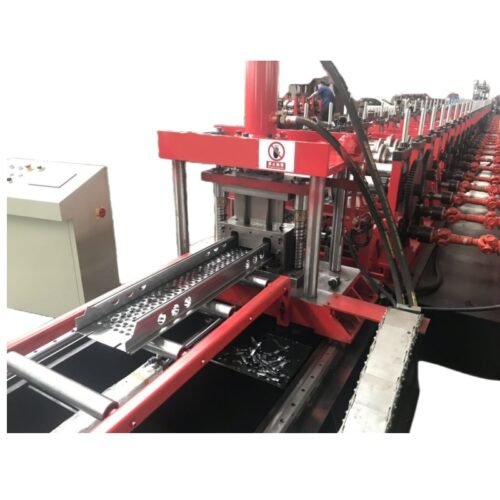

Highly Versatile Steel Sheet Roll Forming Line for Shelving and Racking Applications

This roll forming machine is designed for the efficient production of slotted shelving panels and pallet racks, widely used in warehousing, logistics, manufacturing, and material handling industries. It supports high-precision, automated production to meet diverse requirements for structural storage systems.

Technical Specifications of Roll Forming Machine

| Item | Specification |

|---|---|

| Sheet Cutting Length | Adjustable |

| Control System | PLC (Delta Brand) |

| Material Thickness | Max 1.2 mm |

| Plate Thickness Compatibility | 0.2–1.0 mm |

| Loading System | Equipped with loading car |

| Working Speed | 15–20 m/min |

| Speed Range | 0–45 m/min |

| Power Consumption | 11 kW |

| Drive Method | Chain Drive |

| Transmission System | Chain-driven |

| Color Options | Customizable |

| Decoiler | Hydraulic or manual |

Production Workflow

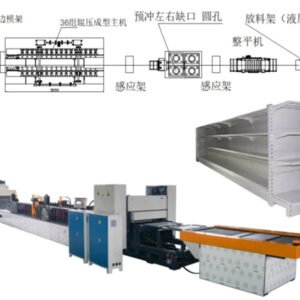

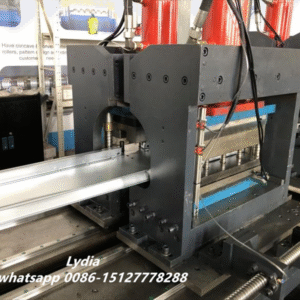

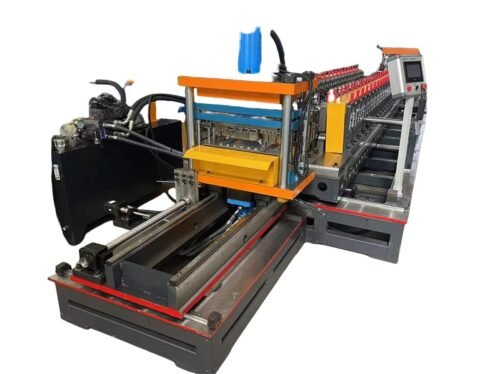

5T manual decoiler → 1000mm leveling unit → 1000mm servo CNC feeder (1.3kW Huichuan servo) + dual-side notch and round-hole hydraulic front punching units (2 mold bases with 4 sets of dies) → 36 forming stations with adjustable width (15kW main motor, frequency control, CNC width adjustment with 0.85kW servo) → hydraulic flanging and cutting (7.5kW oil pump, 1 mold set) → discharging conveyor belt (0.2kW motor).

Line Features and Structure of :

- Material Rack: 5-ton capacity, suitable for coil inner diameters φ450–550mm and outer diameter up to φ1300mm. Passive feeding mechanism.

- Leveling Machine: Processing width from 500 to 1000mm, includes three upper and four lower leveling rollers, plus two sets of pinch rollers. Leveling roller diameter is φ50, and pinch roller diameter is φ58.

- Servo Feeder: 500mm feeding width powered by a 1.3kW servo motor, with feed rate of 15–25 m/min. Pinch rollers are hard-chrome plated after high-frequency treatment.

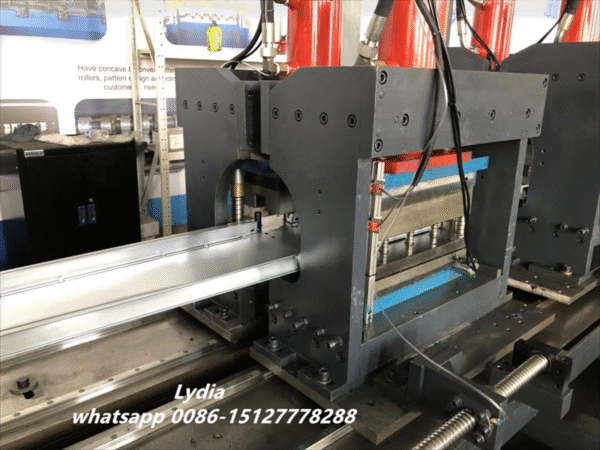

- Front Punching Unit: One 15-ton hydraulic mold base with pre-punching capability for side notches, using two sets of molds—one per side.

- Guiding Mechanism: Assists material alignment for accurate entry into the roll forming section.

- Roll Forming System: Comprising 36 stations, rollers are made from Cr12MoV, vacuum heat-treated to HRC55–58 hardness. Shafts (φ50) are built from tempered 45# steel and precisely ground. Transmission side features tapered roller bearings (30209 x2) and cylindrical roller bearings (NJ209 x1) on the operation side.

- Drive System: Powered by a 15kW main motor with gear reducer and variable frequency speed control.

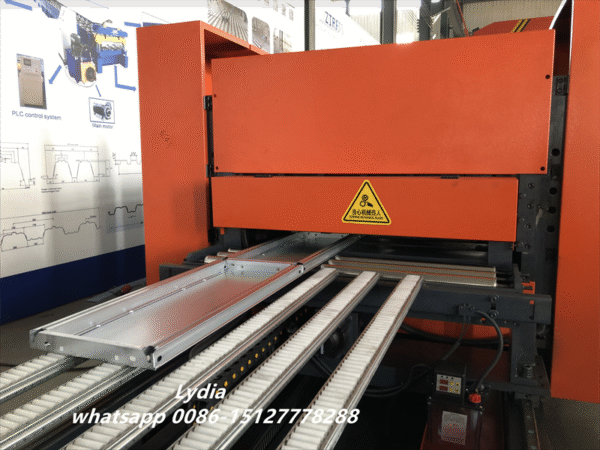

- Hydraulic Cutting & Flanging: Equipped with 25-ton hydraulic cylinder, with built-in protection to prevent misoperation during unloading.

- Discharge Conveyor Table: 2 meters in length.

- Centralized Control System: Integrated PLC system using Huichuan servo control, Mitsubishi PLC (Japan), and Shenzhen Sine inverter for synchronized automation. Xinjie touch screen is used for parameter input. Alarm features include: material shortage stop, batch counting, output completion halt, emergency stop, mold jam, and limit position alerts.

- Pneumatics: Core pneumatic components are from AIRTAC, a well-known brand in Taiwan.

Reviews

There are no reviews yet.