FL-105 & FL-15 Interlocking Wall/Soffit Panel Machines – High-Precision Hydraulic Drive Roll Forming Machine

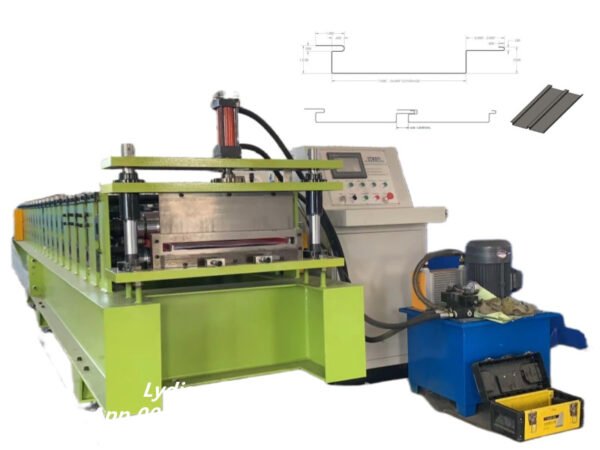

The FL-105 1 Inch Interlocking Wall/Soffit Panel Machine and the FL-15 1.5 Inch Interlocking Wall/Soffit Panel Machine are advanced metal forming solutions designed for commercial wall cladding and architectural soffit systems. With hydraulic drive, a front scissor shear, and adjustable panel widths, both machines support high-speed, precise, and consistent roll forming.

To make it easier to compare both models, a technical comparison table is included below.

Product Comparison Table (FL-105 vs FL-15)

| Specification | FL-105 (1 Inch Flush Wall/Soffit) | FL-15 (1.5 Inch Interlocking Wall/Soffit) |

|---|---|---|

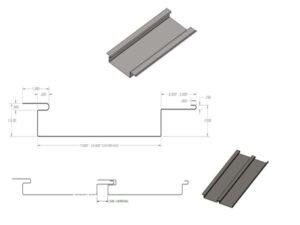

| Panel Height | 1 inch | 1.5 inch |

| Drive System | Hydraulic drive | Hydraulic drive |

| Shear Type | Hydraulic front scissor shear | Hydraulic front scissor shear |

| Power Unit | 3 HP electric-hydraulic (110V, single phase) | 3 HP electric-hydraulic (110V, single phase) |

| Panel Width Range | Adjustable 10″ – 24″ | Adjustable 10″ – 24″ |

| Production Speed | 40 ft/min | 40 ft/min |

| Material Capacity | 24ga steel / .032 aluminum / 12–16 oz copper | Same as FL-105 |

| Optional Accessories | Digital controller / Quick-release ribs / Perforation die / 3K–5K decoiler / Machine stand | Same as FL-105 |

| Best For | Flush wall panel systems & soffits | Deep interlocking wall panels & architectural facades |

Key Features of the FL-105 Interlocking Wall/Soffit Panel Machine

Designed for standard 1-inch commercial flush systems, the FL-105 provides exceptional panel flatness and smooth seams. Moreover, its adjustable forming width ensures compatibility with multiple design requirements.

Core Advantages

- The hydraulic drive ensures stable and powerful forming.

- Hydraulic front scissor shear delivers clean and accurate cuts.

- Adjustable width from 10” to 24” provides strong application flexibility.

- Compatible with a variety of metals, including 24-gauge steel, .032 aluminum, and 12–16 oz copper.

- 40 feet per minute forming speed increases productivity significantly.

Because of these benefits, the FL-105 is widely used in modern commercial buildings, soffit installations, and architectural interior-exterior finishing projects.

FL-15: Enhanced 1.5 Inch Interlocking Wall/Soffit Panel Machine

The FL-15 model features a 1.5-inch profile, which provides deeper engagement between panels and stronger structural rigidity. As a result, it becomes ideal for architectural facades requiring fast installation and enhanced mechanical strength.

Standard Features

- Hydraulic-powered forming and cutting.

- Front scissor shear for precision trimming.

- Adjustable 10″–24″ panel width.

- High accuracy forming for wall cladding and vented soffit applications.

Thanks to its deeper profile, the FL-15 meets the needs of designers seeking bolder lines and enhanced panel durability.

Optional Accessories & Production Enhancements

To support more advanced manufacturing needs, both machines offer multiple upgrade options:

Automation & Precision

- Digital Controller for fully automatic operation

- Quick Release Seam Ribs for rapid profile changes

Soffit Ventilation

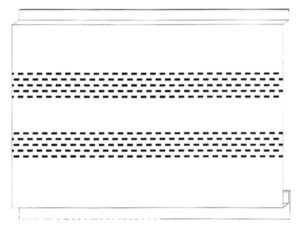

- Perforation Die Attachment for vented soffit panels

- Power Upgrade for forming perforated 24–22 gauge steel

Material Handling & Installation

- 3,000 lb & 5,000 lb Decoilers

- Machine Stand with leveling pads for workshop use

These options help manufacturers maximize efficiency and expand product capability without replacing the main forming line.

Applications Across Building & Architectural Markets

Both FL-105 and FL-15 machines can be used in:

- Commercial façade systems

- Residential soffit and exterior wall panels

- Modern building decoration

- Ventilated soffit systems

- Architectural cladding projects

- Light commercial and industrial buildings

Because both models offer adjustable widths and multi-material support, they are widely adopted by fabricators serving architects, contractors, and metal building suppliers.

The FL-105 and FL-15 Interlocking Wall/Soffit Panel Machines deliver superior flexibility, accuracy, and long-term durability. With hydraulic drive, adjustable panel width, high-speed production, and multiple accessory options, these machines provide a complete solution for modern architectural wall and soffit panel manufacturing.

Reviews

There are no reviews yet.