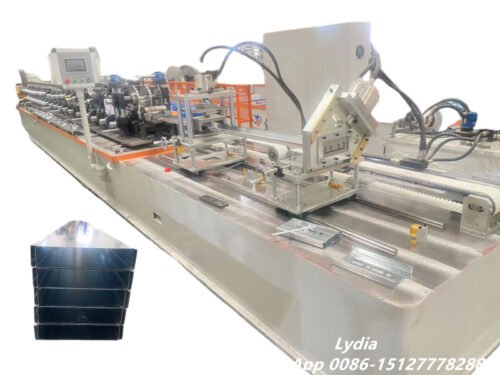

This precision roll forming system manufactures critical edge-protection components for drywall systems and tiled surfaces. Engineered to transform galvanized steel, aluminum, or stainless steel coils into dimensional L-trims, corner beads, and hat profiles, it delivers exceptional dimensional consistency and structural integrity. Integrated rotary punching unit synchronizes perforation with continuous material feed, eliminating production interruptions while maintaining ±0.1mm punching alignment at operational velocities up to 25m/min. PLC automation governs length control, punching sequences, and cutting operations.

| Subsystem | Capabilities |

|---|---|

| Rotary Punching | Continuous in-motion perforation, customizable punching patterns, zero-feed interruption |

| Multi-Profile Tooling | Supports L-trims, corner beads, hat profiles, and custom angles (15°–135°) |

| Precision Forming | Equipped with hardened alloy rollers, adjustable station geometry, supports material thicknesses of 0.4–1.2 mm |

| Automated Cutting | Hydraulic or flying shear cutting options, distortion-free trimming, ±0.5 mm length tolerance |

Operational Benefits

| Component | Specifications / Features |

|---|---|

| 3 Tons Manual Decoiler | Usage: Supports and uncoils steel coil Type: Passive uncoiling Capacity: 3 tons Width: 300 mm Inner Diameter: 450–550 mm |

| Automatic Oil Filling | Automatic lubrication for coils Prevents dezincification and paint damage |

| Feeding Device | Protects coil material Equipped with handwheels for easy adjustment |

| Main Roll Forming Machine | Roller Fixer: Guide column Frame: Middle plate welded, Memorial arch type Frame Thickness: 20 mm Drive Mode: Gear drive Rollers: GCr12MoV material Shafts: 45# steel, tempered Shaft Diameter: 40 mm Roller Stations: 18 Main Power: 4.5 kW |

| Cutting System | Blade Material: GCr12MoV, quenched Power: Hydraulic Frame: Pillar style with rack & pinion Switch: Non-contact photoelectric Includes: Cutting tools, hydraulic tank, cutter machine Adjustable sizes via feeding width |

| Cutter Automatic Oiler | Provides automatic lubrication for cutter Reduces maintenance time and cost |

| Control System | PLC, transducer, and touch panel from Delta Taiwan Other electrical components: Delta Safety: Movable switch, air breaker, radiator, transformer, leakage protector |

| Receiving Table | Welded steel structure with supported rollers for product collection |

| Hydraulic Station | Upgraded type Low noise operation Equipped with cooling fan for extended service life |

| Thermometer | Real-time monitoring of hydraulic station temperature for easier maintenance |

- Material Efficiency: 22% reduction in coil waste vs. stop-start punching

- Tooling Flexibility:Quick-change cartridge system (≤5min profile switch)

- Quality Assurance: Surface inspection sensors detect forming defects

- Output Capacity: 3,200 linear meters/hour at 0.6mm gauge

Reviews

There are no reviews yet.