Overview of Automatic Metal Profile Stacking System

The Light Duty Stacker for C/Z Purlin Roll Forming Machine is an essential automation device in any metal roll forming production line. It efficiently collects, aligns, and stacks finished purlins or profiles, helping factories achieve higher productivity, reduced labor costs, and safer operations.

By integrating this stacker into your roll forming system, you can save one or two workers per line, minimize handling errors, and enhance production efficiency.

We manufacture stackers in light-duty, medium-duty, and heavy-duty versions, suitable for various roll forming machines such as C/Z purlin lines, tube mills, stud and track lines, and guardrail production systems.

Main Features of Automatic C/Z Purlin Stacker

Modern roll forming lines rely on automation for precision and consistency. The automatic stacker ensures that every finished purlin is placed neatly and uniformly, improving workflow efficiency and production safety.

Technical Parameters of Light Duty Stacker

| No. | Details | Parameter |

|---|---|---|

| 1 | Applicable Specifications | Length: 8 m; Width: 50–250 mm; Thickness: up to 3 mm |

| 2 | Weight Capacity | 120 kg |

| 3 | Palletizing Speed | 5 pcs/min |

| 4 | Transmission Power | K-series reducer motor, 1.5 kW |

| 5 | Swing Power | Helical gear reducer motor, 0.75 kW |

| 6 | Palletizing Power | Servo motor, 2.0 kW × 2 |

| 7 | Vertical Stroke | 1.2 m |

| 8 | Horizontal Stroke | 1.8 m |

| 9 | Palletizing Method | Electromagnetic handling |

| 10 | Counting Method | Photoelectric sensor detection |

| 11 | PLC Brand | Delta |

| 12 | Electrical Components | Schneider |

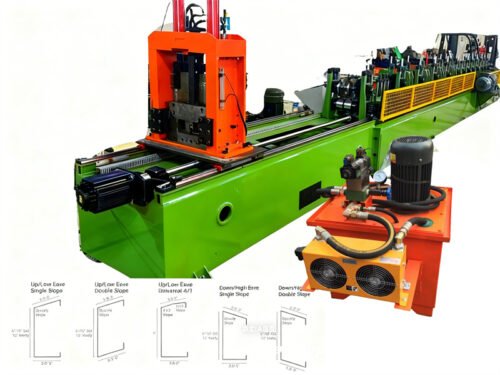

C/Z Purlin Roll Forming Machine with Light Duty Stacker

The Fully Automatic C/Z Purlin Roll Forming Machine is designed for quick size and profile interchange between C and Z sections.

Thanks to its interchangeable roller structure, operators can switch between C and Z profiles without dismantling rollers or spacers.

The universal hydraulic cutting system applies to all profile sizes, meaning there’s no need to change cutting blades, significantly improving efficiency and precision.

Machine Highlights

| Feature | Description |

|---|---|

| Stand Base | Heavy-duty cast iron base ensures maximum stability and long service life. |

| Quick Interchangeable Design | Switch between C and Z profiles simply by rotating the roller set 180°, without removing any parts. |

| Universal Cutting System | One hydraulic post-cutter works for all profile sizes, eliminating blade change downtime. |

| Customized Engineering | Each machine is tailor-made by experienced engineers according to customer profile drawings and layout. |

Technical Parameters of C/Z Purlin Roll Forming Machine

| Item | Specification |

|---|---|

| Product Type | C/Z Purlin Quick Interchangeable Roll Forming Machine |

| Profiles | C Channel / Z Shape (Customizable) |

| Base Material | Galvanized Steel, Hot or Cold Rolled |

| Material Thickness | 1.5–3.0 mm |

| Effective Width | According to Profile |

| Roller Stations | Approx. 16 |

| Roller Material | Bearing Steel / Cr12Mov |

| Drive Type | Chain or Gearbox |

| Machine Frame | 350H / 400H Steel |

| Power Requirement | 15–18 kW |

| Control System | PLC (Panasonic, Siemens, Delta, etc.) |

| Cutting Drive | Hydraulic |

| Cutting Type | Universal Post Cutter |

| Hydraulic Station | 11 kW |

| Blade Material | Cr12Mov (HRC 58–62) |

| Color & Brand | Customizable; SUNWAY standard configuration |

Why Choose Our Automatic C/Z Purlin Roll Forming Line with Stacker

Integrating the automatic stacker with the C/Z purlin forming machine creates a fully automated and efficient production line.

The PLC and servo control system guarantee precise stacking, smooth synchronization, and stable operation throughout the process.

Key Benefits

- Significant labor savings and reduced handling time.

- Consistent output quality for every batch of purlins.

- Customizable solutions according to your plant layout and profile drawings.

- Designed for high-speed, continuous production with low maintenance demand.

If you aim to modernize your metal forming workshop with automated stacking and smart control, this integrated system is your ideal choice.

Reliable Light-Duty Stacking Solution for Roll Forming Line

The Light Duty Stacker for C/Z Purlin Roll Forming Machine offers a practical and efficient way to automate profile collection, improve safety, and optimize workflow.

It is the perfect choice for manufacturers seeking high performance, customization, and cost-effectiveness in their steel purlin production line.

Reviews

There are no reviews yet.