Metal Hat Channel Roll Forming Machine Steel Framing Equipment Manufacturer

A metal hat channel roll forming machine is an advanced piece of steel framing equipment designed to continuously produce hat-shaped metal profiles from galvanized steel, aluminum, or pre-painted steel coils.

These hat channels are widely used in the construction and industrial sectors for wall and ceiling framing, soundproofing structures, and various load-bearing applications.

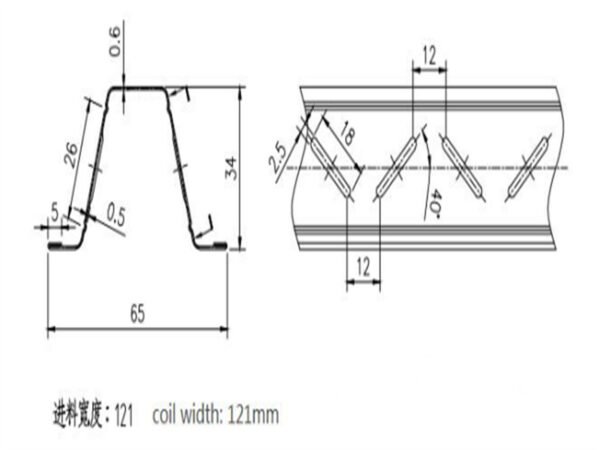

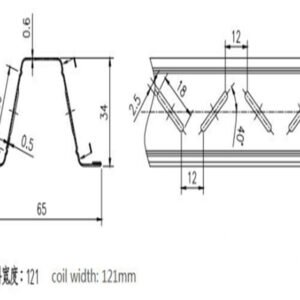

Common Hat Channel Sizes of Hat Channel Forming Machine

| Specification | Typical Range | Notes |

|---|---|---|

| Width | 25–76 mm (1″–3″) | Wider sizes for heavy-duty applications |

| Height | 25–63 mm (1″–2.5″) | Taller sections for greater strength |

| Thickness | 0.5–2.5 mm (16–12 gauge) | Customizable according to load requirement |

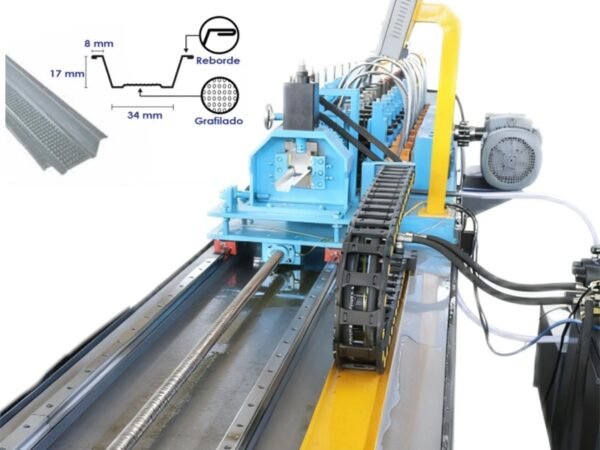

How the Hat Channel Roll Forming Machine Works

- Material Feeding

The production begins with loading a coil of sheet metal into the decoiler. The coil—usually made of galvanized or pre-painted steel—is straightened and fed into the roll forming line for continuous processing. - Roll Forming

A series of precisely aligned rollers gradually shapes the flat metal strip into the hat channel profile. Each forming station performs a specific bending step, ensuring accurate dimensions and smooth surface finish throughout the process. - Cutting System

Once the metal has been formed, the hydraulic or servo cutting unit trims the profiles to the programmed length with high precision.

The PLC control system allows automatic cutting, length counting, and production data tracking. - Stacking & Packaging

Finished hat channels are automatically collected and stacked, making them ready for easy transport and packaging.

Features & Advantages of Hat Channel Roll Forming Machine

- High Precision Forming: Ensures consistent dimensions and perfect symmetry of hat profiles.

- Flexible Adjustment: Quick change of sizes by setting the control system—no complex tooling needed.

- Durable Rollers: Made of high-quality 45# steel with hard chrome plating for long service life.

- Stable Performance: Equipped with PLC control, inverter speed adjustment, and automatic cutting.

- Wide Application: Suitable for drywall framing, metal ceiling systems, partition walls, and industrial structures.

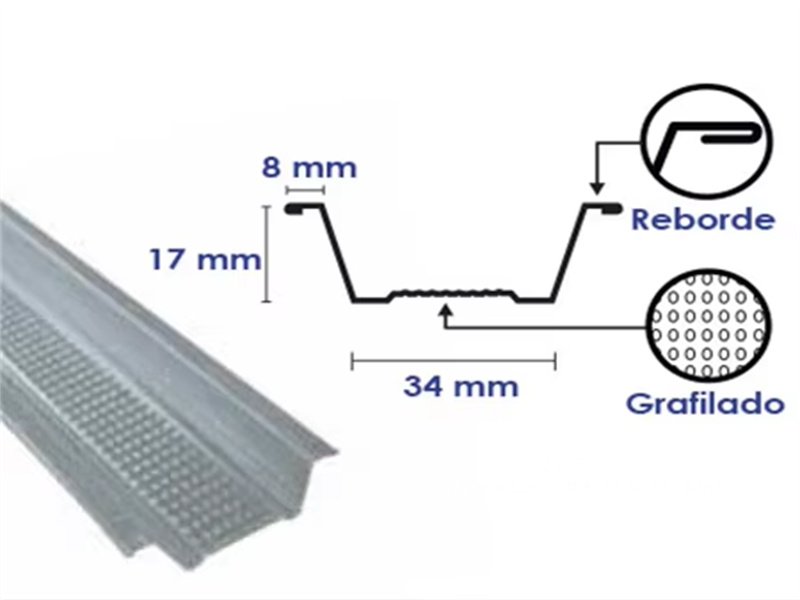

Hat Channel Profile Overview

A hat channel profile, also known as a metal furring channel or drywall hat section, features a flat top (brim) with two vertical sides (flanges).

Its shape resembles a hat or an inverted “U”, providing excellent rigidity and load-bearing capacity while maintaining a lightweight structure.

These profiles are commonly used in:

- Wall and ceiling framing systems

- Soundproofing and insulation installation

- Concealed conduits for wiring or plumbing

- Structural reinforcement in automotive and manufacturing fields

Why Choose Our Hat Channel Forming Machine

- Custom design according to your profile drawing

- CE and ISO certified manufacturing

- 24/7 after-sales support and remote assistance

- Easy operation with a touch screen and a Mitsubishi PLC

- Durable forming rollers and precision cutting blades (Cr12 steel)

Applications of Hat Channel Roll Former

The metal hat channel roll forming machine is widely used for:

- Drywall framing systems

- Metal ceiling grids and partition structures

- Steel frame housing projects

- Automotive and industrial component manufacturing

Conclusion

The hat channel making machine is an indispensable tool for producing high-quality metal hat profiles with consistent accuracy and efficiency.

With its fully automated control system, high forming precision, and versatile design, it plays a vital role in modern construction and metal fabrication industries.

Reviews

There are no reviews yet.