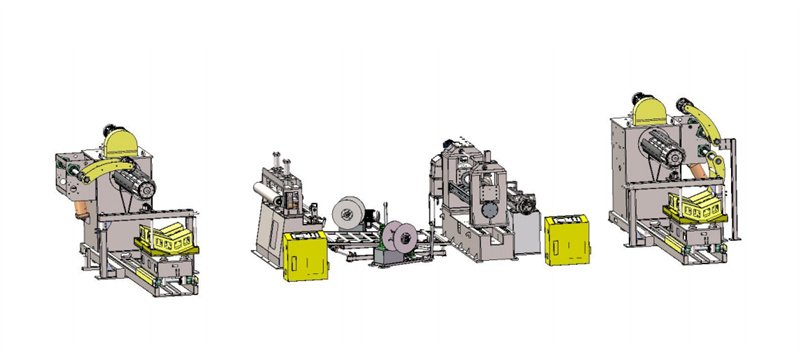

I. System Workflow of Simple Slitting Line

This system is designed for high-speed precision slitting of steel coils into strips of specified widths. It consists of four main components: an uncoiler, precision rotary blade holders, a tension station, and a recoiler, supplemented by auxiliary devices, including material handling equipment, pinch rollers, a lead trimmer/scrap chopper, a loop pit, guiding devices, edge trim winders, and discharge units.

Process Overview:

-

Steel coils are loaded onto the uncoiler via a loading car.

-

A hydraulic shear trims the leading edge to remove irregular sections before being fed into the slitter by lateral guides.

-

The material is slit into strips, with edge trim collected by dedicated winders.

-

Strips pass through a loop pit and separator before entering the tension station, which establishes and maintains uniform tension.

-

Strips are wound under consistent tension to prevent loose or collapsed coils.

-

Finished coils are offloaded using a discharge car and transported away.

The uncoiling, slitting, and recoiling processes are automatically synchronized to prevent material stretching, deformation, or misalignment. The tension station regulates overall strip tension, ensuring uniform coil hardness. The system features automatic length cutting, decelerating and stopping at preset lengths or the coil tail end, supporting both automatic and manual scrap chopping. Operations are fully automated except for initial manual threading.

II.Key Functional Descriptions (Excerpts)

-

Loading Car: 10T capacity, hydraulic lifting & traversing, equipped with remote control.

-

Cantilever Uncoiler: Hydraulic expanding mandrel, 10T capacity, 11kW motor, equipped with disc brake.

-

Guidance & Centering Device: Handwheel adjustment for widths 300–1350mm, chrome-plated vertical rolls.

-

Slitting Machine: Single top knife design, max speed 30m/min, main motor 22kW, knife shaft Φ160mm, utilizes imported NSK bearings.

-

Tension Stand: Press plate type, hydraulically adjusted pressure ensures tight, uniform winding.

-

Recoiler: 10T capacity, 37kW motor, hydraulic expanding mandrel, surface hard chrome plated, equipped with disc brake.

-

Offloading Car: 10T capacity, hydraulic lifting & traversing, includes anti-toppling device.

-

Hydraulic System: 100L reservoir, working pressure 7–14 MPa, 7.5 kW motor, air-cooled.

- Pneumatic System: Operating pressure 0.6 MPa, air consumption 1 m³/min; air source to be provided by customer.

III.Main Technical Specifications

1. Raw Material Specifications

| Item | Specification |

|---|---|

| Material | Aluminum sheet, galvanized steel (GI), galvalume sheet (AZ), cold-rolled steel sheet (flat, no wave or bow) |

| Thickness | 0.3 – 1.5 mm |

| Width | 300 – 1300 mm |

| Max. Coil OD | ≤ Φ1600 mm |

| Coil ID | Φ508 mm |

| Max. Weight | 10 T |

| Tensile Strength | σb ≤ 440 N/mm² |

| Yield Strength | σs ≤ 235 N/mm² |

2. Finished Product Specifications

| Item | Specification |

|---|---|

| Finished Coil ID | Φ508 mm |

| Finished Coil OD | ≤ Φ1600 mm |

| Max. Weight | 10 T |

| Max. Number of Slits | – Cold-rolled sheet (1.5 mm): ≤ 5 strips- Cold-rolled sheet (1.0 mm): ≤ 8 strips- Cold-rolled sheet (0.3–0.6 mm): ≤ 15 strips |

| Min. Slit Width | 25 mm |

| Width Tolerance | ≤ ±0.05 mm |

| Edge Trim Width | 2 – 8 mm |

| Burr Height | ≤ 0.05 mm |

| Slitting Straightness | – Width ≤ 50 mm: ≤ 0.8/1 m- Width > 50 mm: ≤ 0.6/1 m |

3. Machine Specifications

| Item | Specification |

|---|---|

| Slitting Speed | 0 – 30 m/min (Stepless) |

| Threading Speed | 0 – 15 m/min |

| Power Supply | 220V / 60Hz / 3 Phase |

| Total Power | Approx. 95 kW |

| Manning | 1 skilled operator + 2-3 workers |

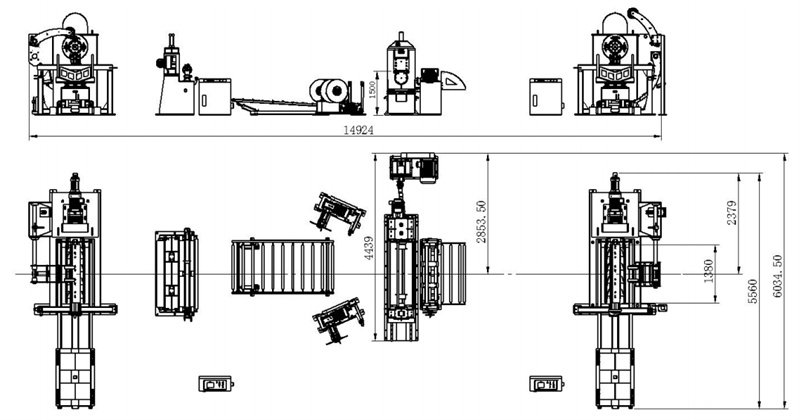

| Footprint | 20 m (L) × 8 m (W) |

| Material Flow | Left to right (facing control panel) |

| Machine Color | Customer specified |

IV.Major System Components

-

-

Loading Car (1 unit)

-

Cantilever Uncoiler (1 set, without hold-down arm)

-

Guidance & Centering Device (1 set)

-

Slitting Machine (1 set, single top knife holder)

-

Material Transition Table + Scrap Edge Winder (1 set)

-

Tension Stand (1 set)

-

Recoiler (incl. Lattice Type Separator) (1 set)

-

Offloading Car (1 unit)

-

Hydraulic Power Units (2 sets)

-

Pneumatic System (1 set)

-

Reviews

There are no reviews yet.