Octagon Pipe Roll Forming Production Line

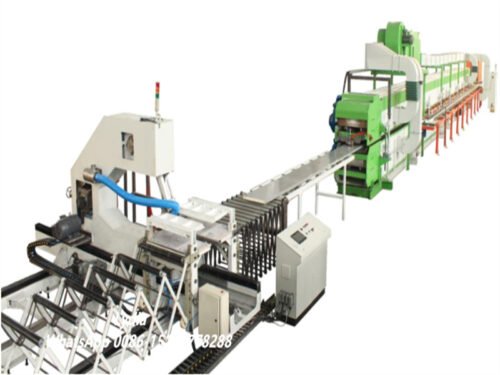

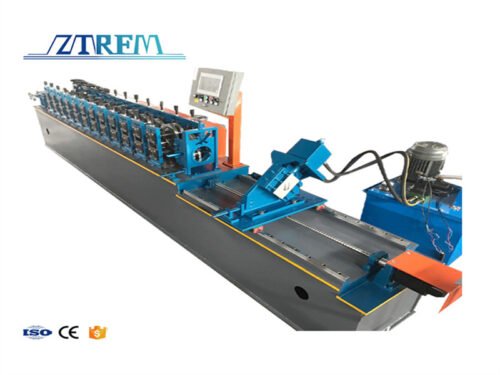

The Octagon Pipe Roll Forming Production Line is a specialized manufacturing system designed to produce high-precision octagon pipes used in applications such as roller shutters, doors, and various industrial structures. With its advanced forming technology, robust construction, and user-friendly control system, this production line ensures efficient, accurate, and continuous operation while maintaining consistent product quality.

The line is engineered for long-term durability and stability, with high-quality rollers, precise guiding systems, and an optimized hydraulic cutting unit. It supports a wide range of materials and thicknesses, meeting the needs of both small-scale and large-scale production.

Production Process The workflow of the octagon pipeline includes:

- Decoiling – Uncoiling the raw material coil.

- Leveling & Feeding – Flattening and guiding material for accurate forming.

- Roll Forming – Continuous shaping of the steel strip into octagon pipes.

- Cutting – Hydraulic cutting with high accuracy.

- Output & Collection – Finished products are stacked and ready for packing.

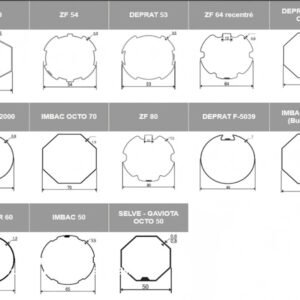

Technical Parameters of Octagon Pipe Roll Former

| Item | Specification |

|---|---|

| Material | Galvanized Steel, Cold Rolled Steel |

| Material Thickness | 0.25 – 0.8 mm |

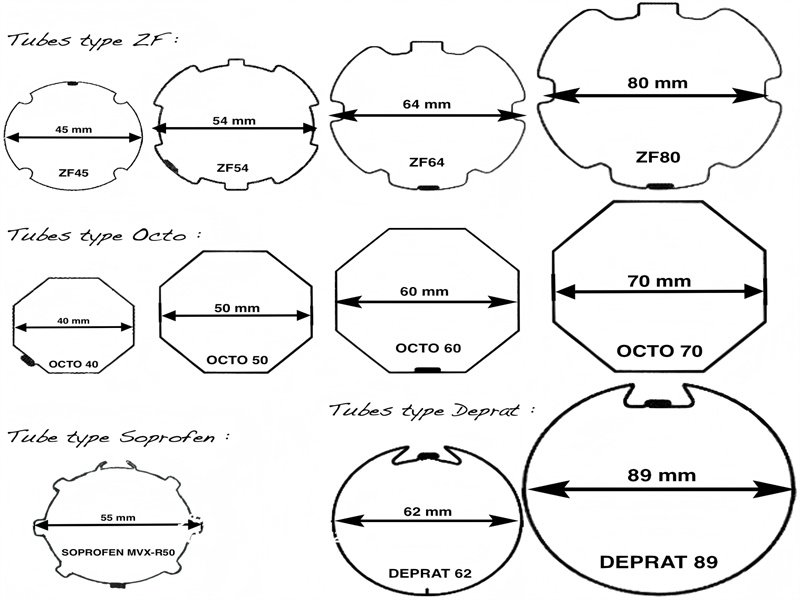

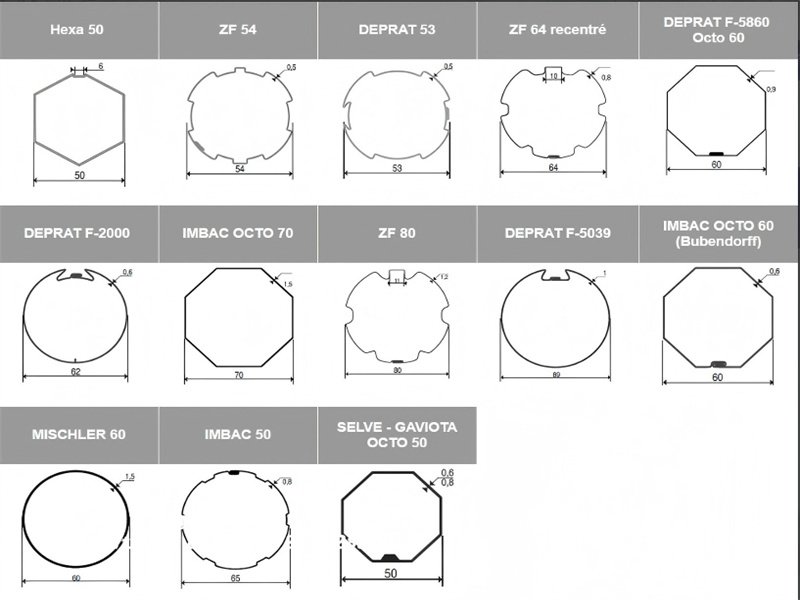

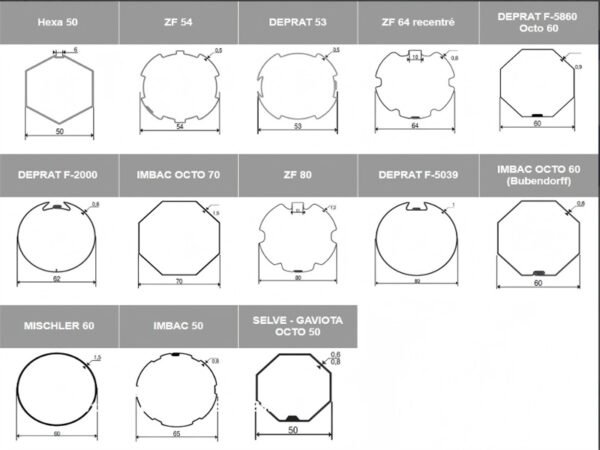

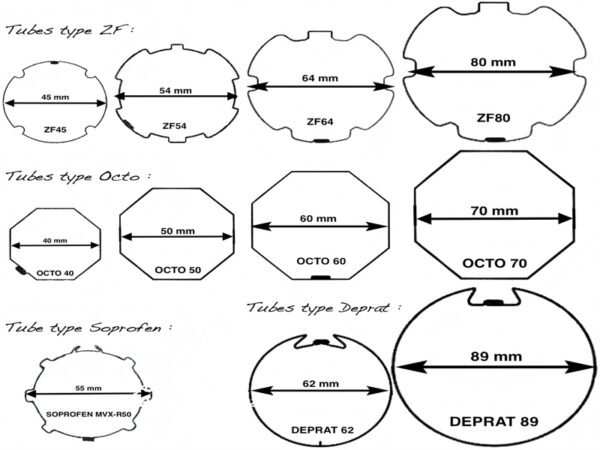

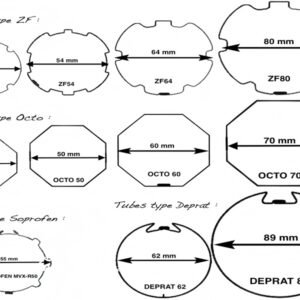

| Pipe Shape | Octagon |

| Pipe Size | 40 mm, 60 mm (customizable) |

| Line Speed | 10 – 15 m/min |

| Roller Material | GCr15 / Cr12, heat-treated |

| Roller Stations | 12 – 16 groups (depending on design) |

| Transmission | Gearbox / Chain Drive |

| Cutting System | Hydraulic cutting |

| Control System | PLC, Touch Screen (Siemens/Delta/Omron optional) |

| Total Power | Approx. 10 – 15 KW |

| Line Length | 12 – 15 m |

Key Features of Octagon Pipe Roll Forming Machine

- High Precision Forming – CNC-machined rollers ensure accurate product dimensions.

- Efficient & Stable Operation – Designed for continuous production with minimal downtime.

- Customizable Design – Pipe sizes and thickness range can be tailored to specific requirements.

- User-Friendly Control – PLC system with touch screen for easy operation and monitoring.

- Durability & Reliability – Heavy-duty frame, hardened rollers, and advanced transmission system.Applications

- Roller shutter doors

- Security doors

- Industrial structures

- Construction materials

- Customized metal profiles

The Octagon Pipe Roll Forming Production Line is an ideal investment for manufacturers seeking efficiency, accuracy, and long-term reliability in pipe production. With its optimized design, flexible customization options, and advanced control system, this equipment guarantees high-quality products and enhanced productivity.

Reviews

There are no reviews yet.