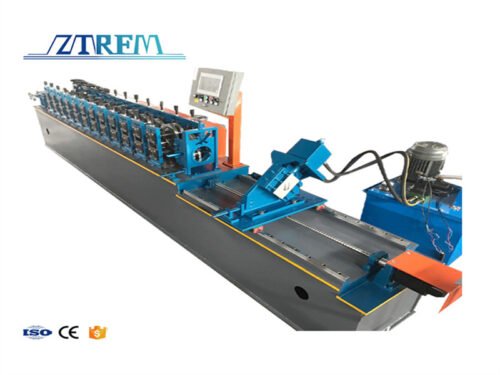

Our ISO and CE-certified Roll-Up Door Roll Forming Machine specializes in fabricating metal shutter door panels, offering adjustable speeds ranging from 15 to 45 meters per minute with full customization options.

This advanced production line is engineered to manufacture diverse rolling door profiles while integrating punching and embossing functionalities. Tailored designs can be accommodated to meet specific project needs.

As a leading manufacturer, Cangzhou Roll Forming Technology employs cutting-edge manufacturing techniques and rigorous quality assurance protocols to guarantee superior performance and durability in every machine.

For comprehensive technical specifications and pricing information, contact our team today.

Key Features and Advantages of Door Shutter Roll Forming Making Machine:

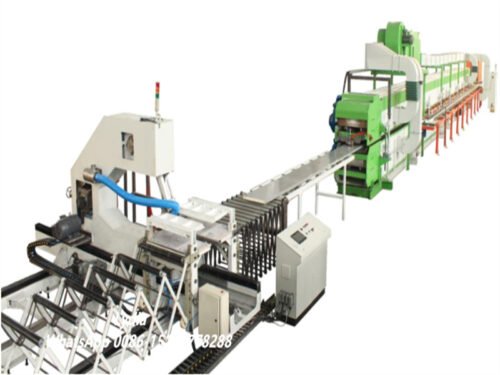

Designed for high-volume output, our Rolling Shutter Door Production Line delivers exceptional efficiency and precision:

-

Adjustable Speed: Configurable at 20, 30, 40, 50, or 60 meters per minute.

-

Enhanced Productivity: Features a continuous flying cut system and automated stacking, achieving speeds up to 60 m/min.

-

Modular Design: Optional cassette-style quick-change platform supports multi-profile compatibility.

-

Certified Quality: Patented technology with CE compliance, meeting European safety and performance standards.

-

Fast Delivery: Select standard-profile machines are available from stock for immediate shipment.

Production Process:

Pre-Cutting Workflow:

Uncoiling (manual/auto) → Material Feeding & Guidance → Leveling → Precision Punching (profile-dependent) → Pre-Cutting → Roll Forming → Manual/Automatic Stacking (optional)

Post-Cutting Workflow:

Uncoiling (manual/auto) → Material Feeding & Guidance → Leveling → Precision Punching → Roll Forming → Hydraulic Post-Cutting → Manual/Automatic Stacking (optional)

Operational Principle:

Roller shutter doors function via an interconnected panel system that glides along vertical tracks, with the upper section serving as a rotational axis for smooth opening/closing. Widely used in commercial, residential, and industrial settings, these space-efficient doors provide secure closures where conventional walls are impractical.

Key components include:

-

Interlocking curtain panels

-

Dual side guides

-

Reinforced brackets

-

Motorized reel assembly

-

Control unit with limit switches

-

Emergency manual override

-

Safety sensors

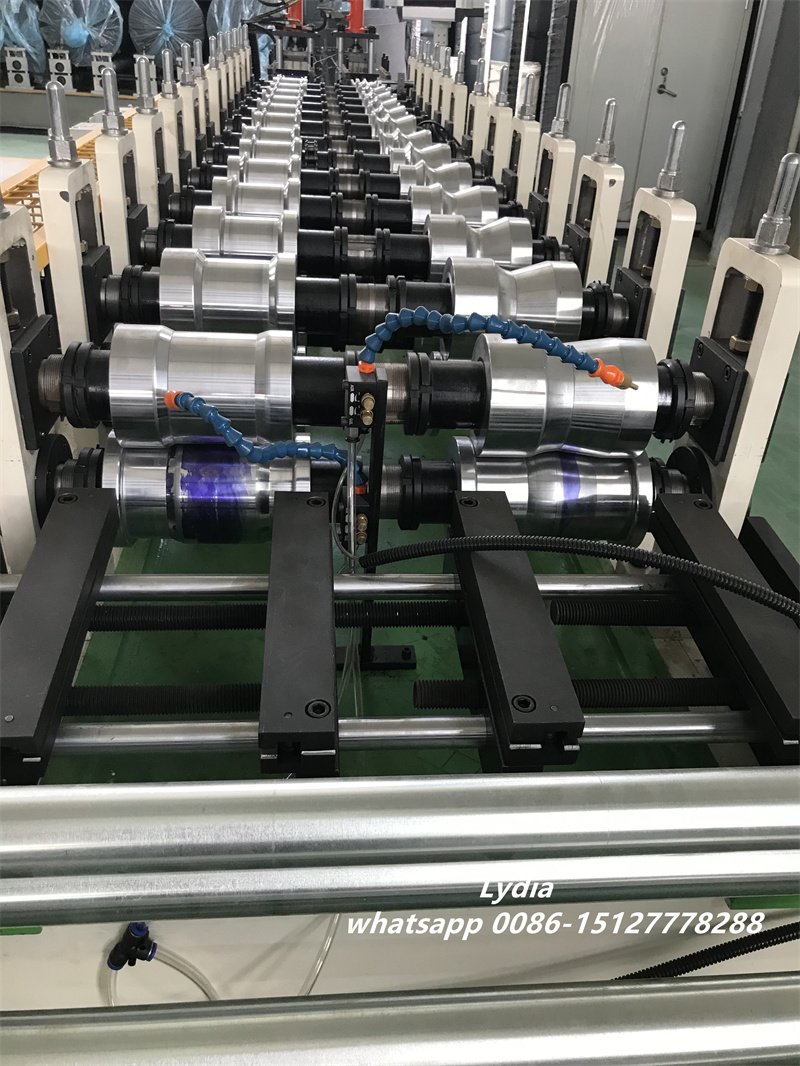

Technical Parameters of Shutter Door Machine:

| Specification | Detail |

|---|---|

| Material | Galvanized Steel (0.6-1.2mm thickness) |

| Decoiler | Hydraulic automatic / Manual (complimentary) |

| Forming Stations | 12-stand (customizable) |

| Roller Shaft | 50mm solid steel |

| Roller Composition | 45# chromium-plated steel |

| Drive System | Gear/chain or gearbox transmission |

| Dimensions | 5500×800×1200mm (customizable) |

| Cutting Mechanism | CR12MOV steel blades (scratch-resistant) |

| Power Requirements | 7.5KW main motor + 5.5KW hydraulic system |

| Voltage | 380V/50Hz/3-phase (configurable) |

| Control System | Siemens PLC with multi-language interface |

| Production Speed | 15-45 m/min (adjustable) |

Reviews

There are no reviews yet.