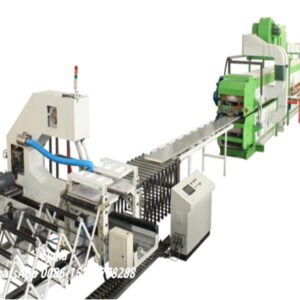

Automatic Steel Sectional Garage Door Panel Production Line

ZTRFMFORMING has dedicated itself to expanding its global footprint in the sectional garage door roll forming industry by strengthening its sales and service network. As one of the experienced garage door machinery manufacturers in China, ZTRFMFORMING can supply a full range of sectional garage door production lines.

Sectional overhead doors are made of multiple horizontal panels that open vertically. Because the panels fold up and lie flat under the ceiling when open, this design saves both interior and exterior space, making it easier to park vehicles directly in front of the garage

Production Line Options

-

Vertical Lift Overhead Garage Door Line

-

Discontinuous Garage Door Production Line

-

Sectional Overhead Door Machine

ZTRFMFORMING sectional garage door equipment ensures durability, safety, and ease of operation. These doors are among the fastest-growing industrial and commercial solutions worldwide, offering reliable sealing, smooth vertical lifting, and space-saving advantages.

Vertical lift doors are suitable for both interior and exterior applications, with customizable options in steel or aluminum. They can be designed according to specific requirements such as insulation performance, wind resistance, door size, or visual appearance.

Process Flow of a Discontinuous Sectional Door Line

A complete vertical lift sectional overhead door production line typically includes the following steps:

-

Decoiling → Leveling → Embossing → Cut-to-length

-

Hot pressing to form decorative patterns (e.g., cube or custom designs)

-

Shutter panel roll forming

-

PU foaming and hot pressing

-

Packing process

-

Finished garage door delivery

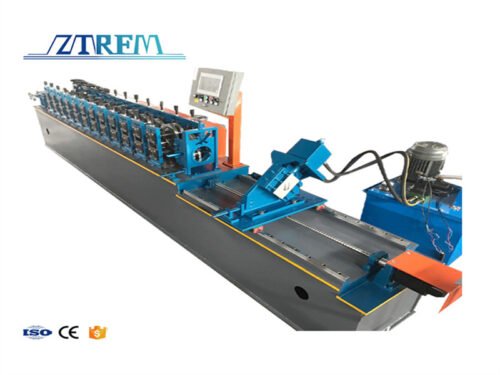

Key Components & Technical Data of Sectional Garage Door Roll Forming Machine

1. Decoiler

-

Capacity: 5 tons

-

Coil inner diameter: φ480–φ508mm

-

Coil outer diameter: max φ1000mm

-

Cantilever width: 400mm

2. Roll Forming Unit

-

Stations: 41 forming rollers

-

Rollers: 45# steel, heat treated (HRC 58–62°)

-

Shaft diameter: φ60mm, quenched and tempered

-

Main motor: 15KW

-

Transmission: Gearbox (chain optional)

-

Frame: 350# H-beam, stress-relieved

-

Bearing: HRB 30213

3. Foaming Machine

-

PU mixing tanks, no-block nozzle

-

Materials: Polyol + ISO

4. Roller Heating Belt

-

Roller dia.: 5mm

-

Roller groups: 40

-

Material: Rubber

-

Length: 8m (depending on panel width)

5. Hydraulic Station

-

Motor: 4KW

-

Cooling: Air fan

6. Electrical System

-

Frequency inverter: DELTA

-

PLC: DELTA

-

Touch screen: DELTA

-

Encoder: Omron

-

Low-voltage components: Schneider

Additional Garage Door Forming Machines Available

-

Channel track roll forming machines

-

Support strut forming machines

-

Sliding door roll forming machines

-

Bottom rail roll forming machines

-

Vertical track forming equipment

Advantages of Sectional Garage Doors

Sectional garage doors are increasingly used in private garages, residential complexes, and public parking areas because they:

-

Roll up quickly with smooth operation

-

Feature wider slats for extra safety

-

Require minimal installation space, ideal for lower ceiling heights

-

Provide noise reduction, thermal insulation, and fire resistance

With over 14 years of experience in manufacturing sectional garage door production lines, ZTRFFORMING offers tailored solutions based on client drawings or samples. Machines are designed to process galvanized steel, PPGI, or aluminum sheets ranging from 0.3–0.7mm thick, with a typical panel width of around 3 meters.

Each complete production line combines decoiler, roll forming unit, PU injection system, foaming silo, servo tracking saw, and PLC control to ensure efficient and precise operation.

For installation, customers can also obtain matching accessories such as U-profile guide rails, motors, and roller systems. For more details or customized project support, ZTRFMFORMING welcomes inquiries at any time.

Reviews

There are no reviews yet.