K-Style Gutter Fabrication System Technical Superiority:

Introducing our breakthrough gutter production equipment featuring independent polyurethane composite drive rollers paired with chromium-plated floating forming dies. This 2025 engineering achievement redefines material versatility for seamless gutter manufacturing.

Processes all substrate grades up to 24-gauge steel

Eliminates deformation risks through pressure-free forming

Dual rack-and-pinion cutting mechanism ensures clean shearing

Maintains consistent performance across material variations

| Base Frame Structure | 350 H-beam welded |

| Sidewall thickness | 16mm A3 Carbon Steel seamless welded with base frame |

| Roller Stations | 18 forming units |

| Connect Bar | Diameter 25mm galvanized steel rod |

| Roller Shaft(Solid) | 70mm-0.01~-0.03 with Key-way |

| Shaft Material(Hard) | High grade 45# steel,lathe then polishing smoothly |

| Roller Material(Hard) | High grade 45# steel,CNC lathe then chromed plated 0.05mm |

| Bearing type | standard 6210(Wanxiang,Wuxi), single units inside wall box |

| Screw and bolts | Common 8.8 standard |

| Transmission method | 0.6 inch (Jindun,Hangzhou) |

| Driving motor | 4.0KW(Lichao,Shanghai) |

| Motor reducer | 4.0KW (Wujin,Changzhou) |

| Forming speed | 10-12m/min |

Gutter systems serve as critical water diversion infrastructure, channeling precipitation away from structures to prevent moisture damage. Our fabrication equipment produces premium drainage components from corrosion-resistant materials including galvanized and stainless steel.

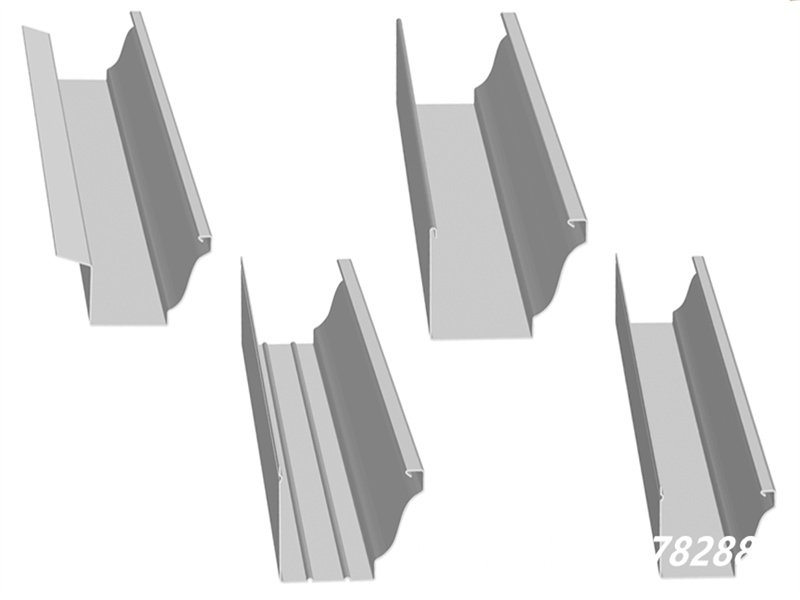

K-Style Gutter Advantages

Characterized by their angular crown molding profile, these systems deliver:

- Enhanced Hydraulic Capacity

Superior volume retention versus rounded designs

- Structural Resilience

Reinforced geometry resists impact deformation

- Architectural Versatility

Multiple dimensions and material finishes are available

Operational Benefits

Material Flexibility: Processes copper, aluminum, and coated steels

Production Efficiency: 30% faster cycle times than conventional systems

Reduced Maintenance: Precision-ground components extend service intervals

Quality Assurance: Consistent dimensional accuracy (±0.2mm)

Reviews

There are no reviews yet.