This automated roll forming manufactures structural roofing panels for residential and commercial construction, specializing in TR40 and TR60 profiles. Engineered for continuous operation, it processes galvanized and polymer-coated steel coils into precision architectural components compliant with EN 10143 standards.

Voltage: 380V±10% 50/60Hz 3-phase – Certifications: CE, ISO 9001 – Safety: EN 13898-1 compliant guards

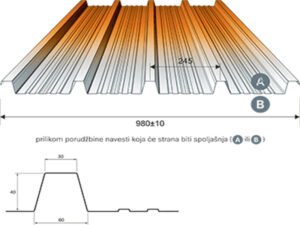

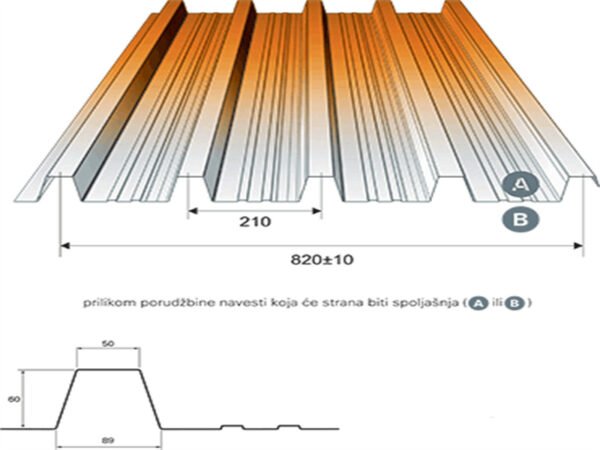

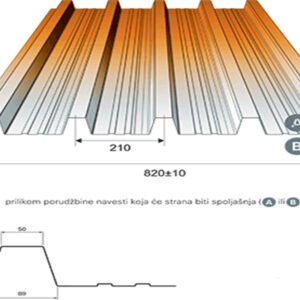

Technical Specifications of Tr40 Metal Roofing Sheets Machine

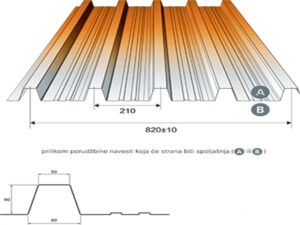

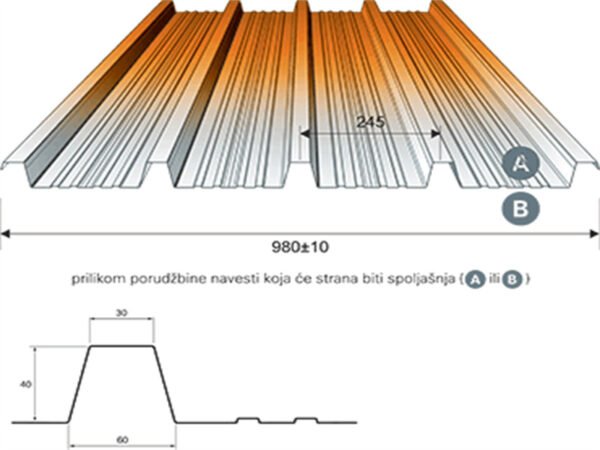

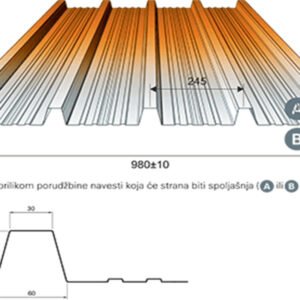

| Parameter | TR40 Profile | TR60 Profile |

| Application | Vertical cladding | Low-slope roofs (>4°) |

| Material | Galvanized steel | Color-coated steel |

| Wave Height | 18mm | 35mm |

| Min. Roof Pitch | Not applicable | 4° |

| Arch Bending | Optional accessory | Not recommended |

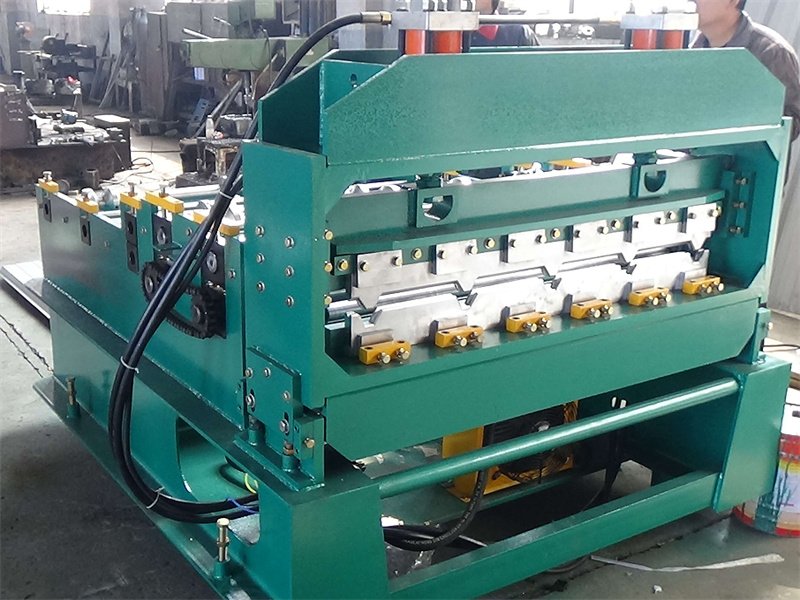

Production Line Configuration Tr40 Metal Roofing Sheets Machine

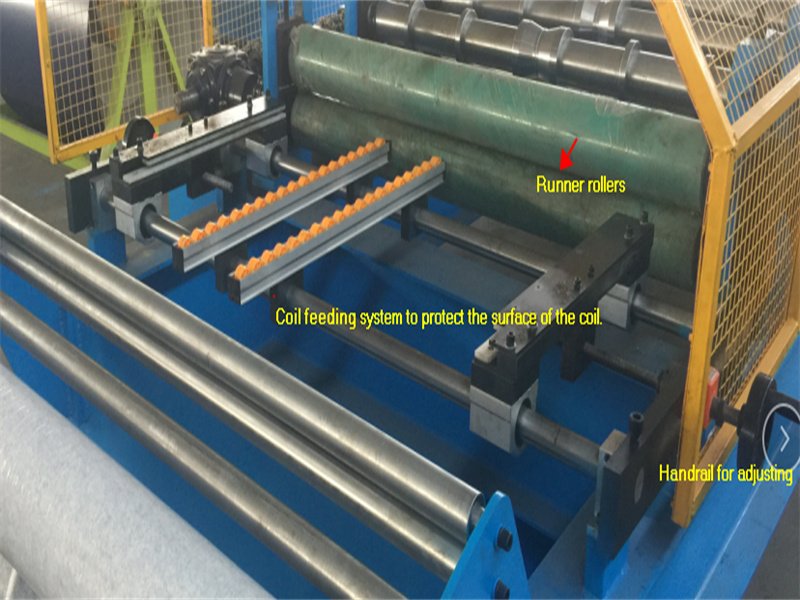

Flow Process: Hydraulic Decoiler → Material Leveling → Double-Layer Forming → PLC Control → Output Conveyor

Core Components

| Component | Specification |

| Coil Handling | 7-ton hydraulic decoiler |

| Material Preparation | Dual-roller leveling with edge guidance |

| Primary Drive | 15kW Siemens motor (dual-layer system) |

| Control System | Mitsubishi PLC with HMI interface |

| Cooling System | Integrated hydraulic temperature control |

Precision Forming System

Structural Framework

- 400H steel welded frame (20mm thickness)

- Machine footprint: 8500×1650×1500mm

- Operational weight: 4.5 tons

Roller Assembly

| Item | TR40 Station | TR60 Station |

| Forming Units | 20 sets | 24 sets (reinforced bearings) |

| Shaft Diameter | Ø80mm | Ø80mm |

| Tooling Material | 45# steel, quenched & chrome-plated (HRC 58-62) | 45# steel, quenched & chrome-plated (HRC 58-62) |

| Surface Protection | Non-marking chromium finish | Non-marking chromium finish |

Drive Transmission

- 25″ precision chain drive

- Dedicated gear system for high-wave profiles

Operational Advantages of the Tr40 Metal Roofing Sheets Machine

1. Dual-Layer Efficiency Simultaneous production of TR40/TR60 profiles

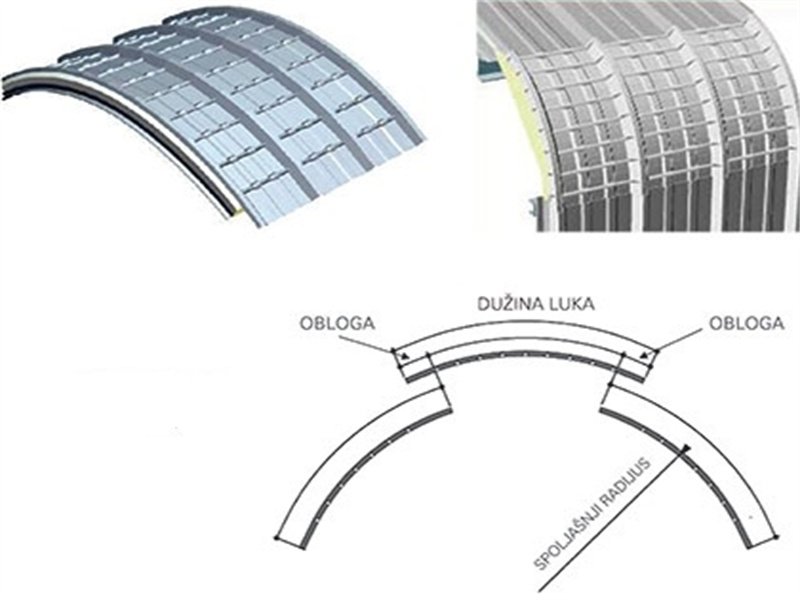

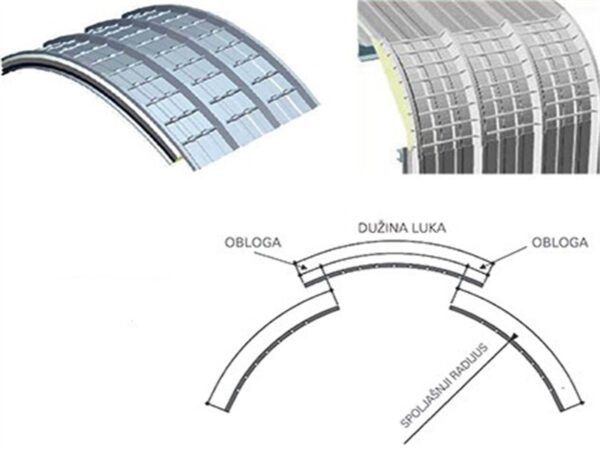

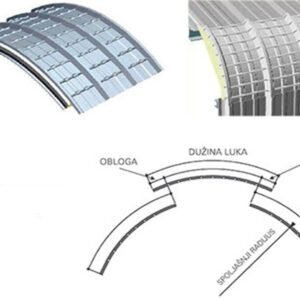

2. Architectural Flexibility: Optional arch-rolling module for curved TR40 applications

3. Production Velocity 25 meters/minute throughput

4. Surface Integrity Scratch-free forming with integrated felt/film application Quality Assurance:

1. ±0.2mm/m longitudinal tolerance

2. Dynamic balancing certified rollers

3. Vibration-damping technology

4. Global Compliance

Arched profiled sheets TR-40 hydraulic bending machine could be designed like this:

Reviews

There are no reviews yet.