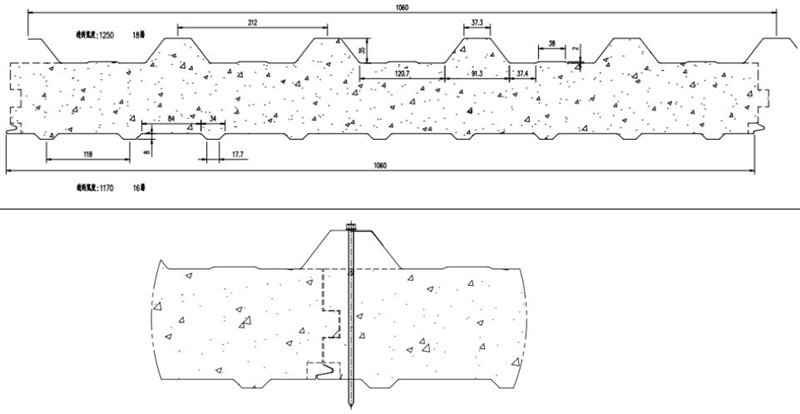

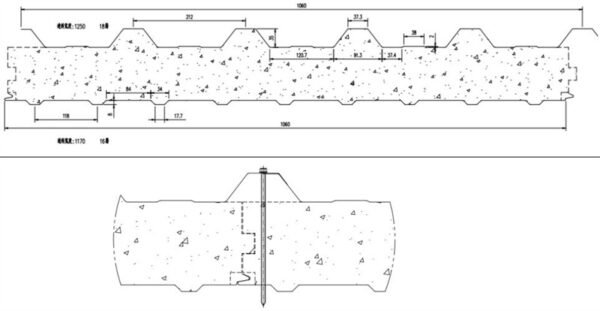

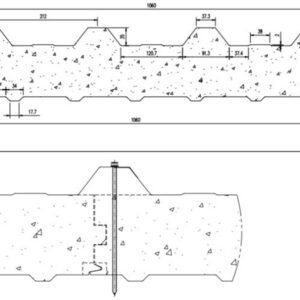

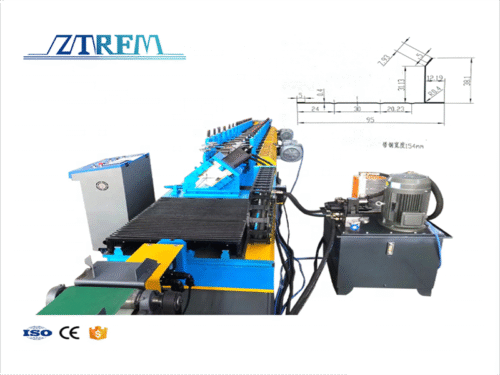

Full-Automatic T18/T35 IBR Roofing Sheet Roll Forming System with Dual-Layer Capability

This advanced roll forming line enables fully automated production of European-standard profiled sheets, including C8, C25, T18, T35, C44, and T44 configurations tailored for Russian and Hungarian markets. Engineered for structural versatility, the system manufactures both single-layer and double-layer roofing/wall cladding panels with precision tolerances.

Technical Note: The T18/T35 IBR profiles feature 18mm/35mm rib heights respectively, while C-series equivalents maintain identical dimensional specifications under regional nomenclature. All systems include automatic stackers and safety interlocks.

This description:

- Integrates both naming conventions (C-series for Russia, T-series for Hungary)

- Highlights the dual-layer capability emphasized in the reference title

- Specifies regional compliance requirements

- Maintains technical precision while avoiding direct copy of phrases

- Organizes features into operational benefits for buyer consideration

- Clarifies profile interchangeability between markets

| No | Type | Specification |

| 1 | Raw Material | Type: PPGI |

| Thickness: 0.3-0.8 mm (or as requested) | ||

| 2 | Decoiler | Operation: Manual |

| Weight Capacity: 5 Tons | ||

| 3 | Main Body | Roller Stations: 17 rows |

| Shaft Diameter: 75 mm | ||

| Shaft Material: 45# steel with 0.05mm chrome plating | ||

| Roller Material: 45# steel with 0.05mm chrome plating | ||

| Type: Chinese type | ||

| Frame: 300mm C-beam | ||

| Frame Thickness: 16 mm | ||

| Cutter Material: Cr12 | ||

| Operation: Hydraulic automatic | ||

| Working Speed: 10-30 m/min | ||

| 4 | Power | Driving Way: 1 inch chain |

| Main Motor: 5.5 KW | ||

| Voltage: 380V/50Hz, 3 phase | ||

| 5 | Control Box | Electric Box: PLC control system, inverter |

| PLC Brand: Delta (Made in Taiwan) | ||

| Inverter Brand: Delta (Made in Taiwan) | ||

| Language: Chinese and English |

Key Technical Features:

- Dual Shearing Options

Hydraulic cutting (high-force applications)

Motor-driven shearing (energy-efficient operation)

- Profile Adaptability

Rapid tooling changeovers between profiles

Accommodates regional naming variants (C-series/T-series)

- Structural Configurations

Single-layer production: 0.3-0.8mm substrates

Double-layer fabrication: Composite insulation panels

- Regional Compliance

Meets GOST standards for Russian projects

Certified for CE-marked Hungarian installations

Operational Advantages:

Automated Production: Uninterrupted operation with PLC-controlled sequencing

Material Efficiency: ±0.5mm width tolerance reduces waste

Output Capacity: 12-18 meters/minute at 0.5mm gauge

Customization: Configured for specific project thicknesses (0.3-1.0mm)

zhongtuo –

Good Machine