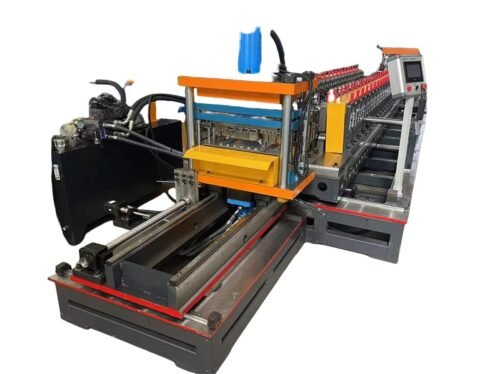

1. Overview of Scaffold Walk Board Roll Forming Machine

The Foot Pedal Cold Bending Forming Production Line adopts coiled metal strips as raw materials.

Through decoiling, continuous roll forming, and automatic cutting, the system produces customized profiles with high dimensional accuracy.

The roll forming section is designed with German COPRA software and simulated using FEA finite element analysis to ensure the highest precision.

The whole line applies PLC control with variable frequency speed adjustment, enabling continuous, automatic, and stable production — ideal for steel structure and metal cold forming industries.

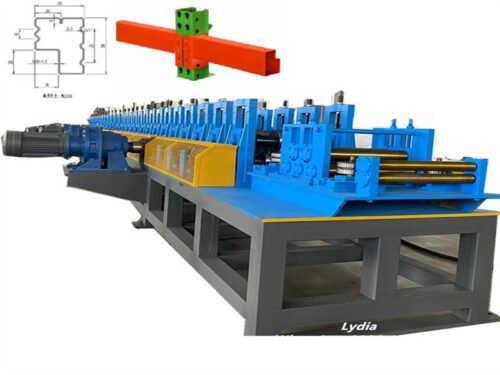

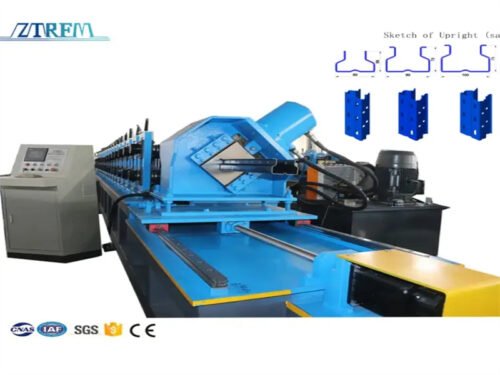

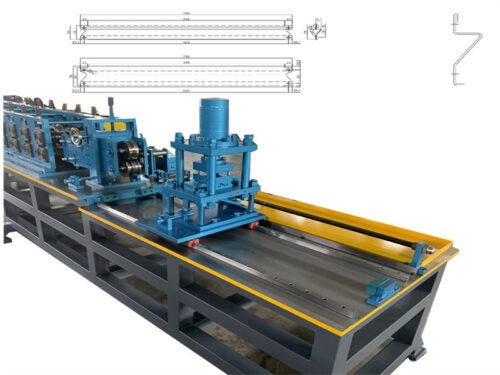

2. Profile Cross Section

The final profile shape will be determined based on drawings confirmed by both parties.

3. Production Process

Decoiling & Leveling 2 in 1 → Servo Feeding + Punching (Stretching & Hole Forming) → Guiding → Clamping → Forming (Closed Triangular Wave Shape) → Riveting → Edge Forming → Riveting → Servo Tracking Saw Cutting

4. Main Technical Parameters

4.1 Decoiling and Leveling Integrated Machine

| Item | Specification |

|---|---|

| Decoiler Type | Passive unwinding, hydraulic tensioning |

| Load Capacity | 5 tons |

| Inner Diameter | φ508 mm (adjustable φ470–530 mm) |

| Roll Width | ≤900 mm |

| Hydraulic Power | 1.5 kW |

| Oil Pump | Gear or vane type |

| Solenoid Valve | Beijing Huade |

| Frequency Converter | Delta |

| Leveling Rollers | 7 rolls (φ52.5 mm), material 40Cr |

| Heat Treatment | High-frequency quenching |

| Leveling Accuracy | ±0.3 mm |

4.2 Servo Feeding & Punching Section

| Item | Specification |

|---|---|

| Feeder Model | NC-900 |

| Servo Motor | Delta 4.5 kW |

| Punch Press | 200T hydraulic punch |

| Main Motor | 15 kW |

| Stroke Speed | 35–50 times/min |

| Material Thickness | ≤2.0 mm |

| Die Set | 1 set core-drawing combined mold |

| Mold Material | Cr12MoV, quenched HRC58–60 |

4.3 Roll Forming Machine

| Item | Specification |

|---|---|

| Structure | Cast iron arch with gearbox transmission |

| Main Frame | Welded high-strength steel with vibration aging treatment |

| Shaft Diameter | Φ80 mm, 40Cr material, CNC precision ground |

| Roller Material | GCr15, HRC58–62, CNC processed |

| Forming Stations | 40 passes + auxiliary rollers |

| Line Speed | 0–9 m/min |

| Main Motors | 2 × 11 kW (K-series gearbox reducer) |

| Bearing | Harbin HRB |

| Spacer Sleeve | Thick-walled tube, precision machined |

| Riveting System | Central + Double-sided riveting |

| Protection | Safety cover on the transmission side |

4.4 Cutting Mechanism

| Item | Specification |

|---|---|

| Type | Servo tracking circular saw cutting |

| Power | 11 kW |

| Clamping | Pneumatic |

| Length Accuracy | ±1 mm |

| Guide Rail & Ball Screw | Domestic top brand |

| Hydraulic Station | 1.5 kW motor power |

4.5 Electrical Control System

| Component | Brand |

|---|---|

| PLC | Siemens |

| Frequency Converter | Delta or Yaskawa |

| Encoder | Koyo (Japan) |

| Touch Screen | MCGS |

| Main Electrical Components | Schneider |

5. Quality Assurance

- Complies with GB/T6725-2008 and relevant industrial standards

- 1-year warranty with lifetime technical service

- Each machine undergoes strict precision testing before delivery

Reviews

There are no reviews yet.