C Post Roll Forming Machine

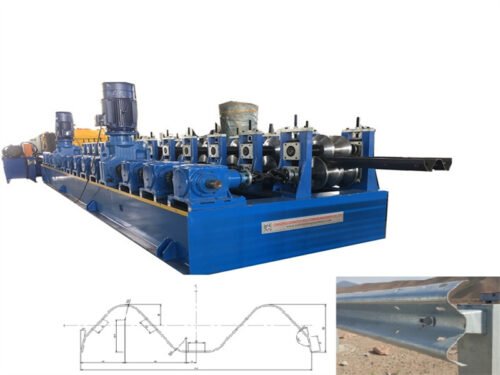

The Sigma Post Roll Forming Machine is a high-performance equipment designed for the continuous production of C post beams, Sigma posts, and highway guardrail components. Manufactured by Xinhonghua Machinery, this advanced metal roll forming line is engineered to produce two-wave and three-wave guardrails, Sigma posts, C posts, and steel guardrail cross beams, as well as guardrail end bending parts used in expressway barrier systems.

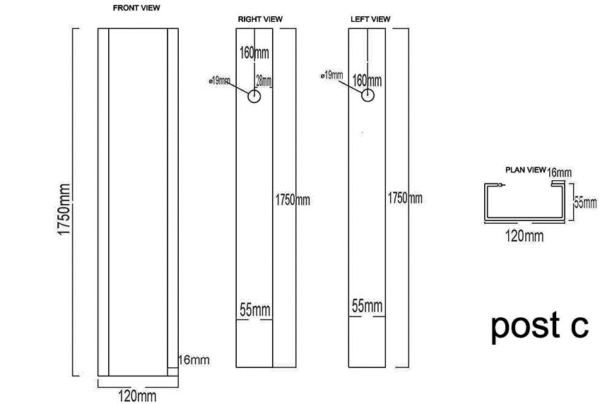

This C Post Beam Roll Forming Machine plays an essential role in producing components for highway guardrails, machinery frameworks, and structural applications. The C-shaped post is widely used for machine supports, enclosures, and building construction due to its excellent strength-to-weight ratio.

Each post features pre-punched holes along the channel, allowing quick installation and easy attachment using bolts.

Machine Technical Specifications of Highway Barrier Production Equipment

| Item | Specification |

|---|---|

| Raw Material Thickness | 4.0–5.0 mm |

| Coil Width | 242–258 mm |

| Material Grade | S-355 or equivalent |

| Forming Speed (With Punching) | 8–10 m/min |

| Forming Speed (Without Punching) | 10–15 m/min |

| Machine Dimension | 35,000 × 3,000 × 1,500 mm |

| Overhead Crane Requirement | ≥10 Tons |

| Estimated Container Loading | 3 × 40GP Containers |

Production Line Layout of Steel Post Roll Forming Line

Workflow:

Hydraulic Decoiler with Traveling Cart → Hydraulic Feeding Table → Leveling Unit → Hydraulic Punching & Pre-Cutting → Roll Forming Machine → Servo Tracking Cutting → Automatic Output Table

This integrated design ensures continuous production, high-dimensional accuracy, and reduced material waste.

Machine Composition

The Sigma Post Roll Forming Production Line consists of:

- Hydraulic decoiler with traveling cart

- Leveling and feeding system

- Hydraulic punching unit with pre-cutting

- Main roll forming unit

- Servo or hydraulic cutting system

- Output table

- Hydraulic power station

- Electrical control cabinet (with PLC touch screen)

The Sigma Post Channel Roll Forming Machine is a robust and efficient system developed to produce sigma-shaped steel posts from coils of various widths and thicknesses. It combines flexibility and precision, supporting a wide range of metal materials, including galvanized steel, carbon steel, and stainless steel.

Equipped with an intelligent PLC control system, the machine ensures high accuracy during forming and cutting, maintaining consistent product quality. With its high-speed forming capability, it delivers reliable performance for large-scale industrial production, making it ideal for manufacturers in the construction, automotive, and agricultural sectors.

Key Advantages of Sigma Post Channel Roll Forming Machine

- Versatile Forming Range: Capable of processing various materials and post profiles, including C, U, and Sigma channels.

- High Production Efficiency: Operates at speeds up to 15 meters per minute, significantly reducing cycle time.

- Precision Control: Advanced PLC system ensures automatic length measurement, batch counting, and fault monitoring.

- Durable & Stable Design: The heavy-duty frame and hardened rollers provide long service life and smooth forming.

- Energy Saving & Low Maintenance: Optimized hydraulic and electrical systems lower operating costs and maintenance downtime.

Each component works seamlessly together to provide stable forming performance, consistent accuracy, and high operational safety.

Applications Sigma Channel Roll Former

The Sigma Post Roll Forming Machine is ideal for producing:

- Highway guardrail posts and beams

- Structural steel supports

- Fence and barrier posts

- Industrial framing components

- Agricultural infrastructure columns

This machine is widely used in infrastructure construction, metal fabrication plants, and civil engineering projects, offering a cost-effective solution for producing durable and precisely shaped metal posts.

Reviews

There are no reviews yet.