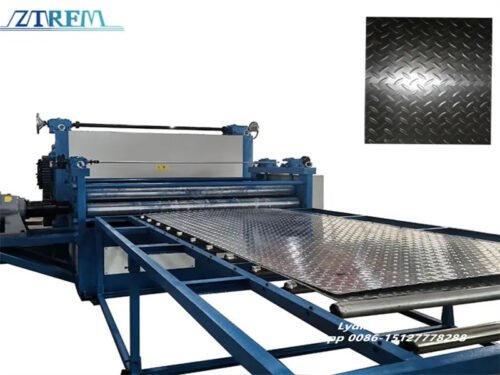

The Snap Lock Roofing Panel Roll Forming Machine SL-1 is a flagship product developed for metal roof panel production. Unlike traditional mechanical lock systems, this machine produces panels with a self-closing lock, simplifying installation.

Technical Benefits of the Standing Seam Roof Machine

Most importantly, the SL-1 allows manufacturers to produce panels with fixation holes for self-tapping screws, making installation even faster. Consequently, it is ideal for roofing projects where both speed and quality are critical.

Choosing between snap lock and mechanical lock standing seam panels can be challenging. However, there are key differences that make snap lock more practical in many cases.

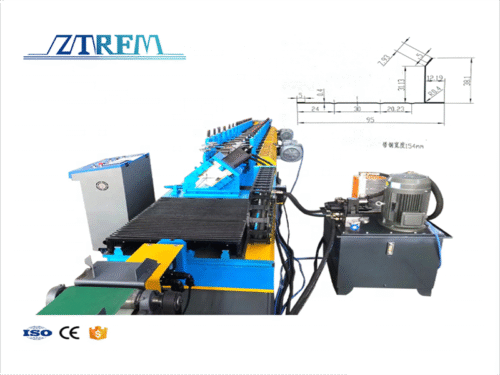

| em | Name | Specifications |

| 1 | Raw material | Galvanized steel and Pre-painted steel |

| 2 | Raw material thickness | 0.3-0.5mm |

| 3 | Decoiler | 5T Hydraulic decoiler(Different capacity for option,manual one for option) |

| 4 | Roller station | 18 stations |

| 5 | Roller material | 45# steel with quenched treatment |

| 6 | Shaft diameter | 80mm |

| 7 | Shaft material | 45# steel with tempered |

| 8 | Transmission | by chain |

| 9 | Motor power | 5.5kw moter |

| 10 | Machine frame | 350H steel welded |

| 11 | Cutting type | Hydraulic cutting |

| 12 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 with quenched treatment |

| 15 | Cutting tolerance | +/-1mm |

| 16 | Control system | PLC |

| 17 | Brand | PLC:Delta/Siemens/Mitsubishi

Touch screen:Delta/Siemens/Mitsubishi Encoder:Omron |

Mechanical Lock Panels

-

Require special seaming tools

-

Need skilled labor

-

More time-consuming installation

Snap Lock Panels

-

Simple connection: press panels until they snap in place

-

No tools required: reduces equipment costs

-

Easy for beginners: even workers with little experience can install

-

Lower cost overall: saves on both labor and accessories

Advantages of the Snap Lock standing seam roof machine

-

Easy installation: just press panels together until you hear a click.

-

No extra tools required: compared with mechanical seam panels.

-

Cost saving: eliminates the need for clips and seaming equipment.

-

High efficiency: reduces labor time and installation costs.

In conclusion, while mechanical lock panels are still used for certain projects, snap lock panels are easier, faster, and more cost-effective. For businesses that want high efficiency with lower investment, the snap lock system is the best choice.

Reviews

There are no reviews yet.