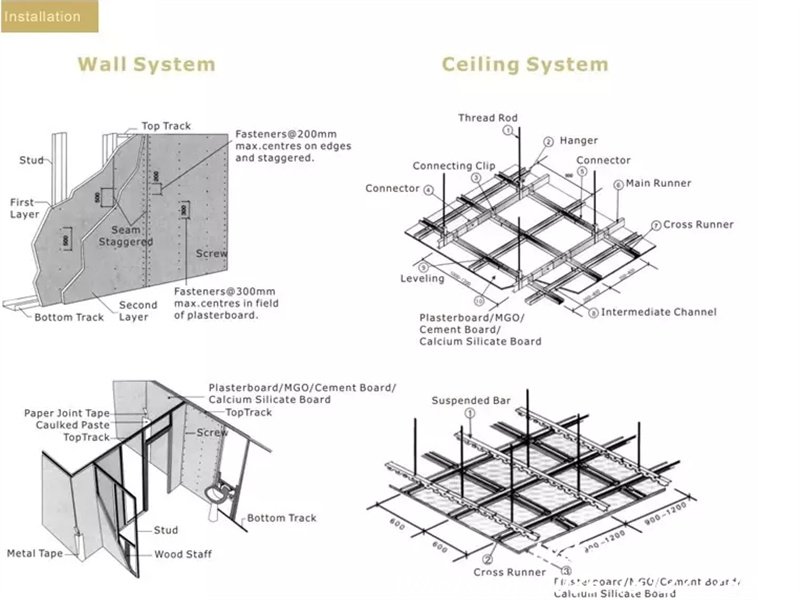

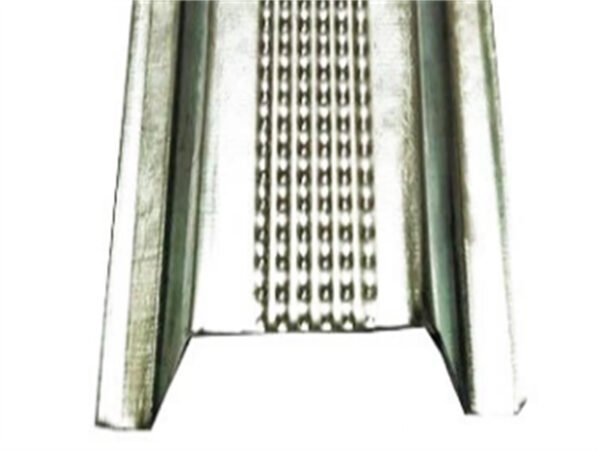

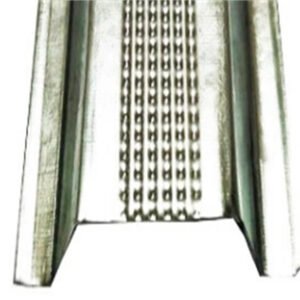

In contemporary building applications, hat-shaped galvanized steel channels have become essential components for creating durable wall and ceiling frameworks. These corrosion-resistant profiles, typically installed perpendicular to masonry surfaces using specialized fasteners, serve as critical substrates for attaching gypsum panels in both vertical and overhead applications. The construction sector’s ongoing pursuit of enhanced productivity and quality assurance has driven significant advancements in roll-forming technology, particularly for manufacturing these vital framing elements.

Manufacturing for Lightweight Steel Framing

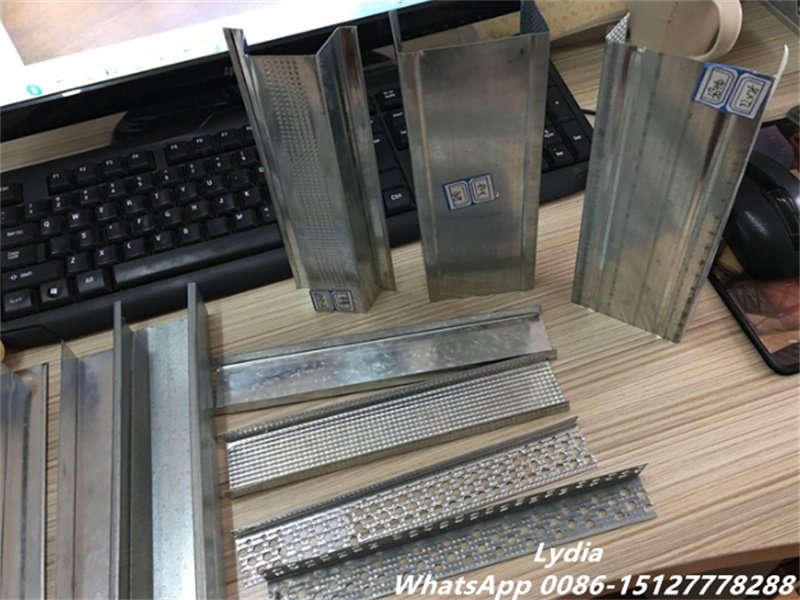

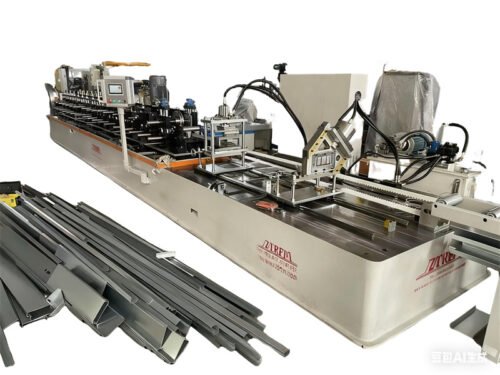

Modern roll forming systems have transformed the production of structural channels used in light-gauge steel construction. Unlike heavy-gauge buildings that employ C or Z purlins, lightweight structures utilize precision-formed hat channels crafted from 0.6-1.2mm galvanized steel. These automated production lines combine multiple processes into a continuous operation, converting raw coil stock into finished framing components with exceptional dimensional accuracy.

Engineering Advantages of Stud Furring Hat Channel Roll Forming Machine

The equipment’s robust construction features a reinforced structural frame that maintains stability during high-speed operation. Premium-grade GCr12MoV alloy forming rollers ensure extended service life, while the integrated servo tracking system guarantees consistent product quality throughout production runs. The machine’s innovative design incorporates 35-40mm thick forming frames to absorb operational vibrations, particularly during maximum velocity production.

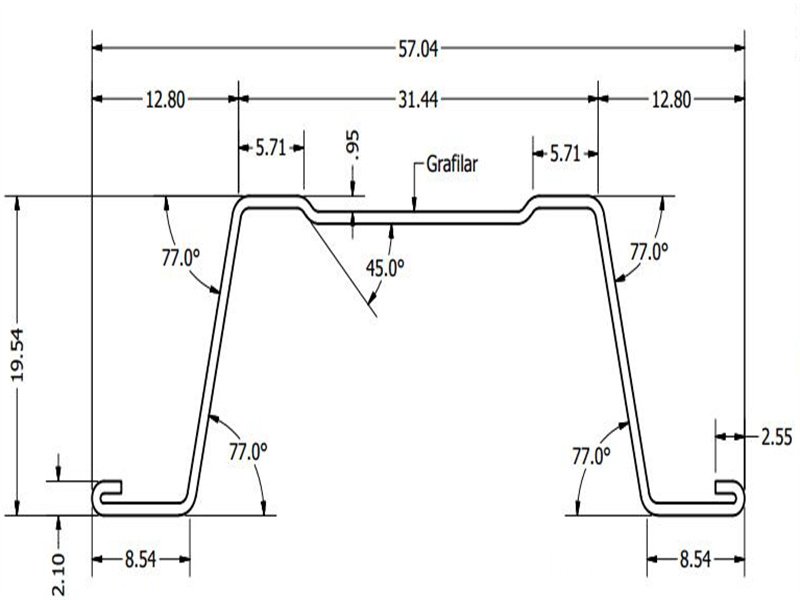

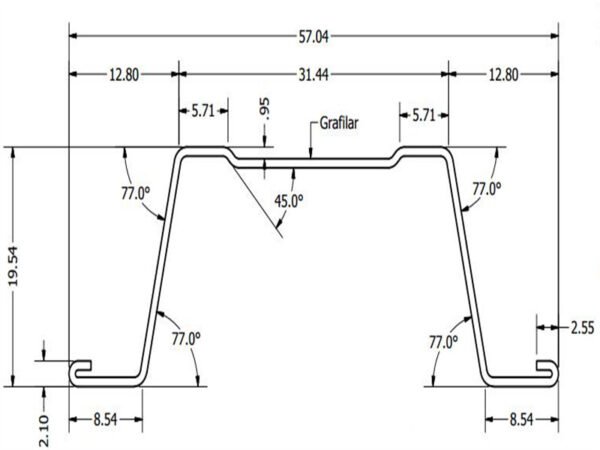

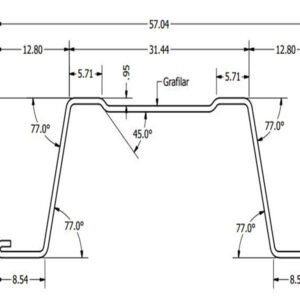

The Drawing Profile :

Key Features of High-Performance Stud Furring Hat Channel Roll Forming Machine:

| Item | Specification |

| Decoiler | Manual decoiler |

| Inner Diameter (I.D) | 508–610 mm |

| Outer Diameter (O.D) | 1000–1200 mm |

| Decoiler Capacity | 3 Tons |

| Roll Diameter | 70 mm |

| Forming Roller Stations | 14 stations |

| Roller Material | 45# steel coated with hard chrome |

| Forming Speed | 0–12 m/min (excluding punching or cutting) |

| Machine Frame Stand | Welded structural steel |

| Thickness of Stand Plates | 18 mm |

| Main Power | 5.5 kW |

| Cutting Type | Hydraulic stop-to-cut |

| Hydraulic Power | 3 kW |

| Cutting Blade Material | Cr12 Steel with quenching treatment |

| Control System | Japanese Panasonic PLC with inverter and Omron encoder |

| Voltage | 380 V, 3-Phase, 50 Hz |

Reviews

There are no reviews yet.