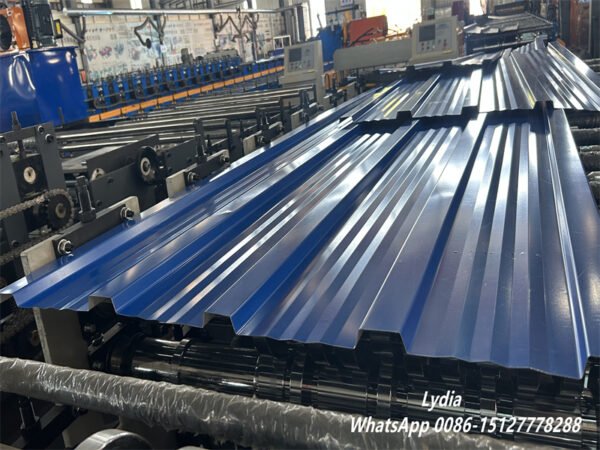

Serbia Popular High-Quality 1090 and 965 Trapezoidal Double Layer Roofing Sheet Roll Forming Machine

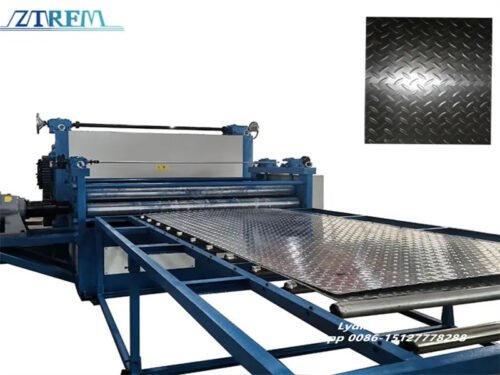

This glazed tile machine is designed for prefab houses and produces galvanized steel roofing tiles with a step tile profile.

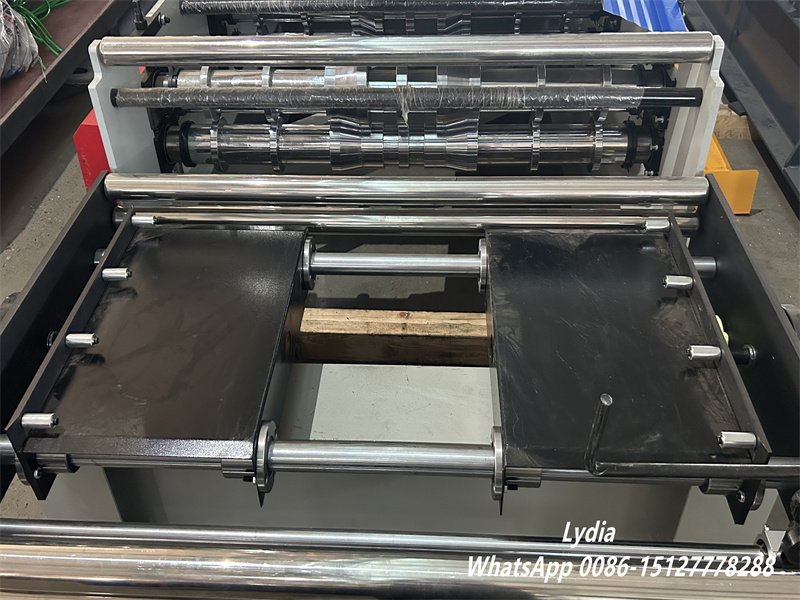

The working principle of the galvanized steel tile machine utilizes a new hydraulic shearing system powered by a gear oil pump.

IBR roofing equipment is a traditional Chinese building material often finished with lead-glazed coatings in colors such as gold, emerald green, and blue, among over a hundred glaze color options. Importantly, these tiles do not suffer from the anti-lead phenomenon that can affect decorative finishes on lead-glazed tiles. Due to their aesthetics and durability, Western-style tiles are increasingly favored in modern construction and are being widely adopted.

New Product Launch: High-Quality TR4 Trapezoidal IBR Metal Roof Sheet Double Deck Roll Forming Machine

- The color metal roofing tile machine is equipped with a hydraulic cylinder that moves the mold up and down to press the color steel into multiple sections, producing a glazed tile-like appearance. The cutting mechanism, also driven by a hydraulic cylinder, moves vertically to accurately shear the colored steel tiles.

- The arch sheet roof tile machine includes a frequency converter-driven motor, a hydraulic station motor, and four hydraulic solenoid valves—two for pressing and two for cutting.

- This metal tile machine supports 14 input signals and 10 relay outputs, sufficient to meet all input/output requirements. It features a KDN text screen for parameter configuration, alarm notifications, help information, and production data display.

- Numerous machine parameters can be adjusted via the text screen, divided into equipment parameters (such as single pulse length, overshoot, pressing distance and time, cutting time) and user parameters (including sheet count, length, section size, last section, pitch, and number of sections).

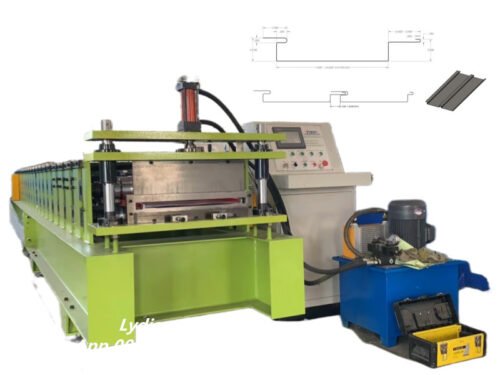

Workflow for TR4 IBR Roofing Sheet Double Layer Machine

Uncoiler → Molding Core → Hydraulic System → Automatic Control System → Step Formed Mechanism → Automatic Shearing Mechanism → Product Receiving Table

| Component | Specifications |

| Decoiler | Quantity: 1 set

Max Width: 1000–1250 mm Inner Diameter: Φ450–Φ550 mm Outer Diameter: 1500 mm Max Load Capacity: 5000 kgs Operation: Passive or hydraulic |

| Feeding Device with Pre-sliding Cutter | Quantity: 1 set |

| Roll Forming Machine | Material Thickness: 0.25–0.8 mm PPGI and GI

Number of Roller Stations: 10–18- Rollers Material: 45# steel, polished & chrome-coated (HRC58–62°)- Shaft Material: High-grade 45# steel, CNC lathe polished- Shaft Diameter: 70 mm (solid shaft)- Frame Panel Size: 16×290×330 mm- Bottom Frame: 350×8 mm H steel- Motor Power: 3.8/5.5 kW × 2 (servo motors)- Drive Type: Wall plate chain drive- Chain and Gear: 1″ chain- Speed: Approx. 4–6 m/min |

| Cut-off Device | Cut-off Modular Material: Cr12 steel (heat-treated, HRC58–62°)- Cut-off Type: Qualified pillar cutting- Hydraulic Stand Motor: 5.5 kW- Punching Die Material: Cr12 steel (heat-treated) |

| PLC Control Box | Type: PLC frequency control system with touchscreen- PLC Brand: Delta- Encoder Brand: Omron- Length Error: ±2 mm- Language: English and Chinese- Voltage: 380 V / 50 Hz, 3-phase (customizable) |

| Hydraulic Pump Station | Oil Type: 46# hydraulic oil- Pump Brand: Domestic Chinese brand- Motor Power: 5.5 kW- Solenoid Valves: Huade brand- Valve Type: Single solid valve- Cooling Method: Fan |

| Production Support Table | Manual type or automatic stacker available |

Reviews

There are no reviews yet.