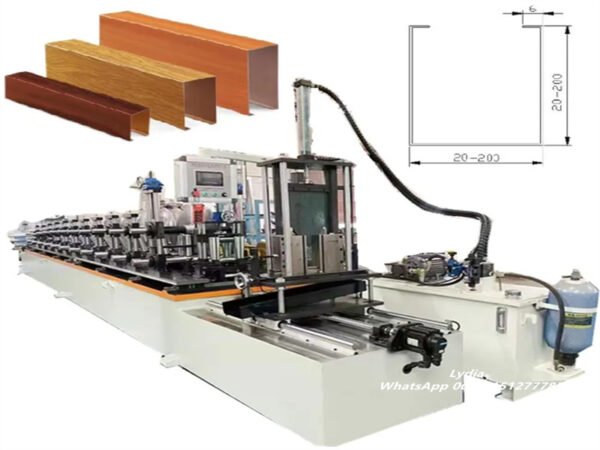

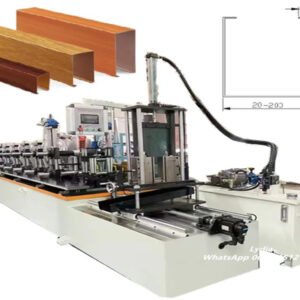

Product Details of U Baffle Acoustic Ceiling Machine

The U Baffle Acoustic Ceiling Machine is an advanced roll forming system designed for the continuous production of U-shaped ceiling baffles widely used in commercial and architectural interior decoration. This machine ensures smooth feeding, accurate forming, high-precision cutting, and stable long-term performance—making it an ideal solution for ceiling manufacturers seeking high efficiency and premium product quality.

Engineered for versatility, the U-baffle ceiling roll forming machine supports a wide range of material sizes and thicknesses, delivering reliable output for both aluminum and color-coated steel baffles. With a robust PLC control system and high-speed forming process, this production line guarantees precise lengths, clean cuts, and flawless surface finishes.

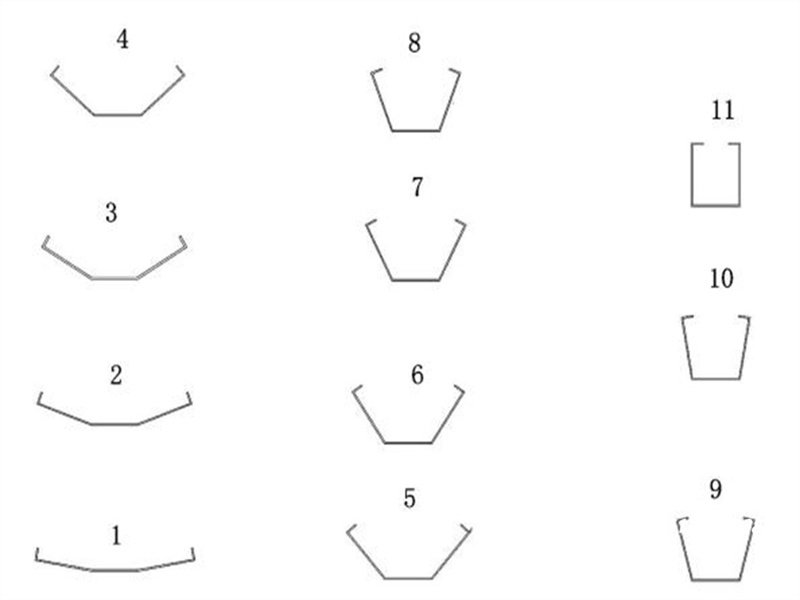

Profile Range & Material

Profile Specifications

- Profile Width: 20–200 mm

- Flange Height: 20–200 mm

Applicable Materials

- Aluminum Coil: 0.3–1.2 mm

- Color Steel: 0.27–0.45 mm

Supports a broad range of U-baffle ceiling design requirements.

Technical Specifications of U-baffle ceiling design requirements

| Item | Specification |

|---|---|

| Machine Type | Automatic U Baffle Acoustic Ceiling Roll Forming Machine |

| Speed | 10–50 m/min |

| Control | PLC (Panasonic/Delta) |

| Decoiler | Manual / Hydraulic |

| Cutting Type | Hydraulic Fly Cutting |

| Material Strength | 235–345 MPa |

| Container Loading | 1×40′ GP |

| Production Capacity | 600 sets/year |

| Warranty | 1 year + lifetime technical support |

Key Features of the U Baffle Ceiling Roll Forming Machine

1. High-Precision Forming System

The machine feeds the coil material through a guiding device and gradually shapes it using high-precision forming rollers.

- Rollers: GCr15 steel, quenched & precision-ground

- Roller Stations: 14 groups

- Shaft processing: Double grinding for dimensional accuracy

- Structure: 60mm precision arch columns ensure long roller life

This ensures perfectly formed U-baffle profiles with consistent dimensions.

2. Fly Cutting System with Encoder Control

Equipped with a hydraulic fly-cutting mechanism, the cutting blade moves synchronously with the product during cutting, ensuring non-stop production.

- Cutting mold material: CR12MOV

- Length control: Encoder positioning (tolerance within ±1mm)

- Operation: Smooth, fast, and stable without production interruption

This design significantly improves efficiency and precision.

3. Automatic Decoiler (Manual or Hydraulic Options)

The machine includes a durable decoiler system to support easy coil loading and smooth feeding.

- Expansion range: 450–520mm

- Max capacity: 1 Ton

- Feeding speed: Matches forming line speed

- Optional hydraulic decoiler with coil car for heavy-duty operations

4. Sheet Guiding Device

Ensures the coil enters the forming system in accurate alignment.

- Components: Steel platform, guide rollers, position blocks

- Function: Stable feeding and correction of material position

5. Hydraulic Station

Provides stable power for cutting operations:

- High-quality hydraulic components

- Oil tank, pump, electromagnetic valves

- Energy-saving design—runs only during cutting

- Ensures no leakage and long-term durability

6. Un-Powered Stacker

A 3m discharge table equipped with rollers for easy movement and stacking of finished profiles.

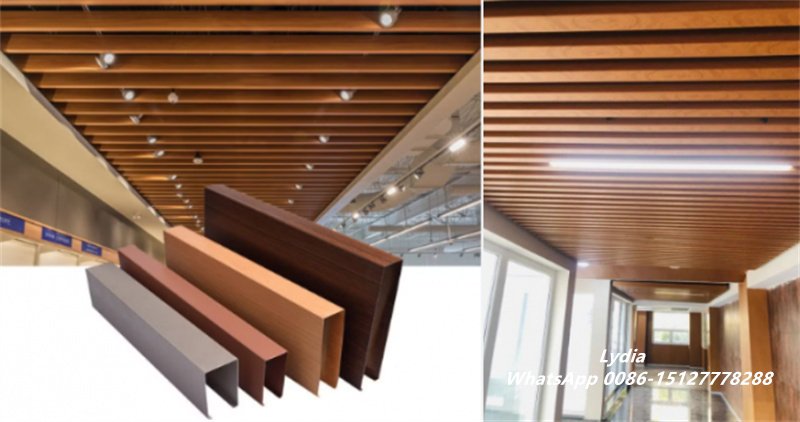

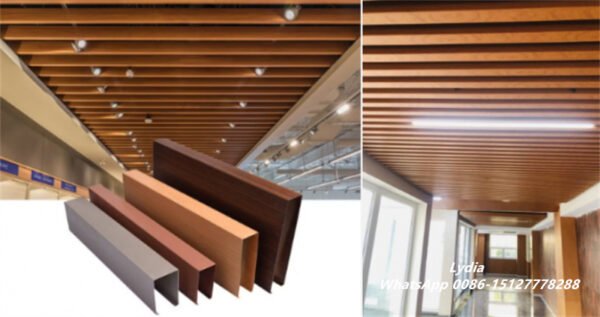

Applications of U Baffle Acoustic Ceiling Panels

The U-shaped acoustic ceiling baffles produced by this machine are widely used in commercial building decoration, including:

- Shopping Malls

- Airports & Railway Stations

- Hotels & Restaurants

- Exhibition Centers

- Office Buildings

- Conference Halls

- Public Spaces & Interior Design Projects

These ceilings offer excellent aesthetics, acoustic performance, and modern architectural appeal.

Why Choose This U Baffle Ceiling Machine?

- High forming accuracy

- Fast production speed

- Low length error

- Multi-size adjustable

- Stable hydraulic system

- Durable roller and cutter materials

- Suitable for aluminum and steel

- Lifetime technical support

This acoustic ceiling panel machine helps manufacturers significantly enhance productivity while ensuring premium-quality U-baffle profiles.

Reviews

There are no reviews yet.