When it comes to long-lasting and weather-resistant roofs, Ultra-Dek standing seam metal panels are one of the best options. They are designed as snap-together trapezoidal leg panels and have passed Air Leakage and Water Penetration testing approvals.

Key Features of Standing Seam Roll Forming Machine

-

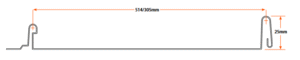

Available widths: 18-inch & 24-inch

-

Seam height: 1 3/4″

-

Minimum slope: ¼:12

-

Panel materials: steel, aluminum, or copper

Why Choose Ultra-Dek Panels?

Firstly, they are durable and can withstand extreme weather. Secondly, they are versatile, since they can be installed on different construction types. Finally, their clean appearance makes them suitable for industrial, commercial, and even architectural use.

| Technical parameters | ||

| Series | Details | Parameter |

|

Product sheet |

Raw material | PPGI & GI |

| Material thickness | 0.3-0.8mm | |

| Effective width | As request | |

| Sheet cutting length | Adjustable | |

| Part 1: 5 ton Decoiler | ||

| Decoiler | Work type: passive type | |

| Structure;Steel channel welded for the basic frame | ||

| usage:To support the coil and make the uncoiling | ||

| Loading capacity: 5 tons | ||

| Inner diameter: 600mm | ||

| Coil width: 1000mm | ||

| Brake system: manual brake | ||

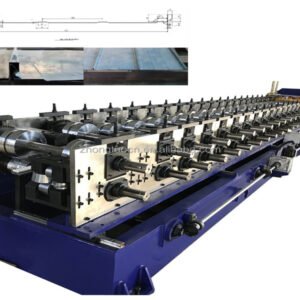

| Part 2: Main roll former | ||

|

Roll forming machine |

Feeding device | Steel plate welded as the feeding platform |

| One set guiding roller | ||

|

Rolling shaft |

Shaft material:45# STEEL | |

| Shaft type: solid shaft | ||

| Shaft diameter: 70 mm | ||

| Tempering treatment to prevent deformed and improve hardness | ||

| Roller | 45# steel, | |

| Rolling station | 18 rolling stations | |

| Machine structure | Middle wall plate structure 16mm | |

| Work speed | 0-10 m/min | |

| Machine structure | Carbon steel welded structure | |

| Machine basic frame | 350# H steel welded | |

| Anti rusty treatment after welding | ||

| Work power | 5.5 kw | |

| Part 3: PLC control system | ||

|

Control system |

Frequency brand | Delta |

| PLC brand | Delta | |

| Frequency brand | Delta | |

| Screen type | Touch screen, also have buttons on the panel | |

| Screen language | English/Chinese/Spanish | |

| Cut command | Yes | |

| Profile length set-up | Yes | |

| Batch quantity program | Yes | |

| Low pressure part | Schneider brand | |

| Encoder | Omron brand | |

| Part 4: Hydraulic cutting system | ||

|

Hydraulic system |

Work type | Hydraulic cutting |

| Driving method | By pillar type Cylinder | |

| Hydraulic motor power | 5.5 kw | |

| Cutter material | GB-Cr12 | |

| Cutting length tolerance | ±1mm/3m | |

| Cutting feature | Steady and safe working condition | |

| Pre-shearing system | Decoil – feeding – pre-shearing – roll forming – receiving | |

With Ultra-Dek, you get both performance and style for your roofing project.

Reviews

There are no reviews yet.