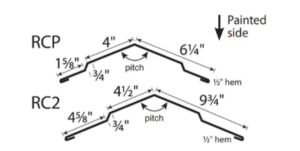

The Ridge Cap is engineered to complement a wide range of metal roofing systems. When installed with closure strips and sealant, it offers reliable protection against water penetration at the ridge seam. Its sharp angles and defined peak contribute to a timeless, clean roofline.

-

Constructed with a durable Galvalume base for extended service life

-

Compatible with roof slopes of 3/12 pitch or steeper

-

Can be easily cut using standard aviation snips

-

Specifically developed for ridge applications on both commercial and residential buildings

-

Complies with or surpasses Energy Star standards

-

Designed with a 1-inch step on both sides of the peak and a total width of 12–14 inche

-

Available in all standard colors, fabricated from 29-gauge metal

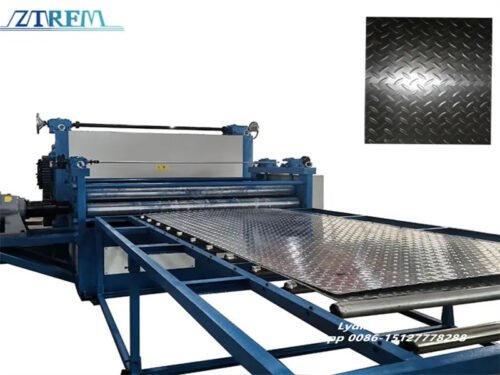

Introduction to the Ridge Cap Forming Machine

This machine specializes in producing ridge caps for metal roofing sheets. While traditional ridge coverings were once made from glazed tiles, modern alternatives such as color steel or aluminum ridge caps offer a lighter, more cost-effective, and easier-to-install method.

Technical Parameters of the Ridge Cap Roll Forming Machine

| Category | Specification |

|---|---|

| Uncoiling System | Manual or hydraulic decoiler |

| Material Thickness Range | 0.3–0.8 mm |

| Substrate | Customizable to customer specifications |

| Machine Dimensions | 7000 × 800 × 1500 mm |

| Feeding Width | Adapted to the profile dimensions |

| Number of Forming Stations | 13–15 |

| Shaft Diameter | 70 mm |

| Shaft Material | High-quality 45# steel, tempered and quenched |

| Roller Material | Premium 45# steel with 0.05 mm chrome plating |

| Production Speed | 10–15 meters per minute (adjustable) |

| Drive Mechanism | Chain transmission |

| Main Frame | 18 mm thick welded structural steel |

| Main Motor | 5.5 kW (Shanghai manufacturer) |

| Cutting Method | Hydraulic stop-cut system |

| Cutting Power | 3 kW |

| Blade Material | Cr12, heat-treated to HRC 58–62 |

| Length Tolerance | ±2 mm |

| Power Supply | 380V/50Hz/3-phase (customizable) |

| Control System | PLC-based operation |

| Control Cabinet Size | 700 × 1000 × 300 mm |

| PLC Brand | Delta or Siemens |

Key Advantages of the Ridge Roll Forming Machine

| Category | Details |

|---|---|

| Warranty | 24-month warranty with extended service life |

| Spare Parts | Includes two complimentary spare parts for each type |

| Training Support | – Online assistance – Instructional videos – Technical video support – Comprehensive operation manual |

| Ease of Use | – Operable by a single person – Customizable PLC interface language |

| Engineering Support | – Custom CAD profile design – OEM and ODM services available |

| Certifications | CE, SGS, ISO, and Certificate of Origin included |

Reviews

There are no reviews yet.