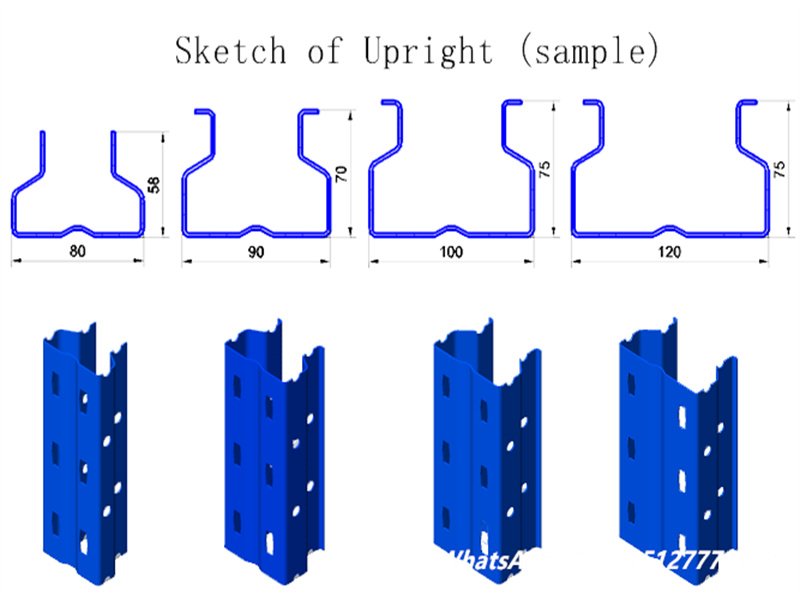

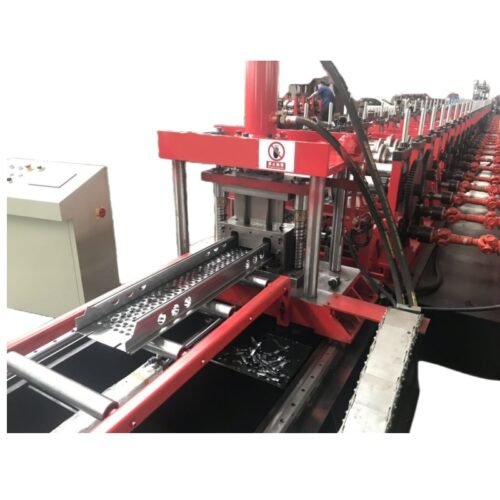

Argentina Warehouse Storage Rack Roll Forming System – Industrial Upright Pillar Production Equipment

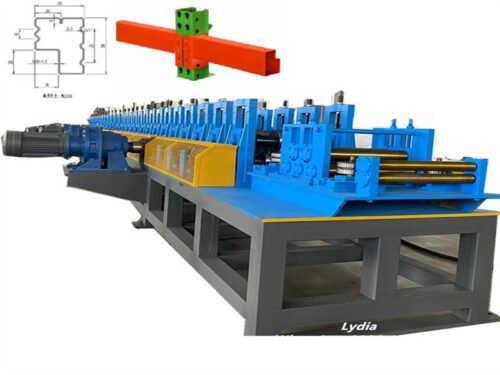

Overview of the Upright Rack Roll Forming System

This high-efficiency Storage Rack Roll Forming Machine is engineered for producing both shelf racks and pallet racking systems, offering flexible storage solutions for diverse applications. It efficiently handles materials up to 2.5mm thick with a production speed of 15-25 meters per minute, making it ideal for high-bay warehouses requiring optimized space utilization.

Key Advantages of the Upright Rack Production Line

-

Precision Engineering – Tolerances maintained within ±1mm for consistent quality.

-

Robust Construction – Reinforced base frame with 82mm solid shafts and H-beam steel to prevent deformation under heavy-duty operation.

-

CNC-Machined Rollers – Ensures dimensional accuracy for seamless rack assembly.

-

Stress-Relieved Frames – Minimizes warping during prolonged use, maintaining smooth surface integrity.

-

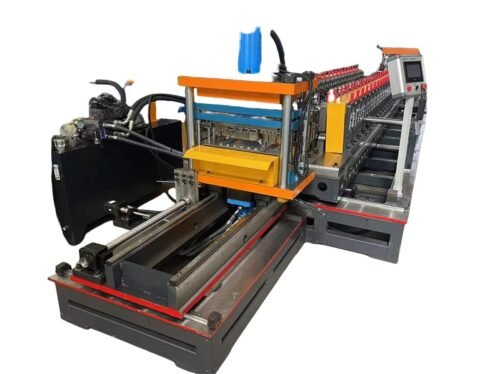

Automated Control – Equipped with Mitsubishi/Siemens PLC for stable performance. Set length and quantity parameters, and the machine auto-processes with a cutting precision of ±2mm

Customizable Racking Machine

ZTRFM offers multiple upright rack machine models, allowing customization in frame height and depth. Each unit includes pre-assembled components, such as vertical posts, diagonal braces, and base plates, for quick and easy installation.

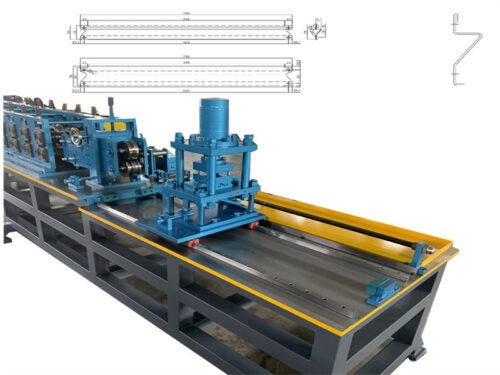

Production Workflow

-

Motorized Decoiler → 2. Precision Punch Feeder → 3. High-Speed Punch Press (with Dies) → 4. Roll Forming Machine → 5. CNC Cutting Unit → 6. Finished Product Conveyor

Technical Specifications

| Category | Feature | Specification | Notes |

|---|---|---|---|

| Material | Base Metal | Galvanized Steel Sheet | Client Approved |

| Thickness Range | 1-2 mm | ||

| Uncoiler | Roller Setup | 7-Roller System (3 Top + 4 Bottom) | Standard alignment for material flattening |

| Max Load | 3 Metric Tons | ||

| Coil Inner Diameter | 450-550 mm | ||

| Roll Forming Unit | Guide Mechanism | Integrated by Manufacturer | |

| Shaft Composition | Heat-Treated 45# Steel | ||

| Shaft Diameter | Ø70 mm | ||

| Roller Hardness | Cr12 Alloy (HRC 56-58) | ||

| Forming Stations | 18 Stages | ||

| Operational Speed | 0-12 m/min (Adjustable) | ||

| Structural Frame | Vertical Arch Design | ||

| Base Construction | Welded Steel Plate | ||

| Bearing Type | Premium Roller Bearings (Harbin) | ||

| Drive System | Dual 11 kW Motors | ||

| Transmission Method | Enclosed Chain Drive | ||

| Safety Features | Full Protective Covers | ||

| Finish & Quality | Surface Treatment | Smooth Paint Coating, No Burrs/Rust | 100% Brand-New Guarantee |

| Optional Upgrades | Hydraulic Decoiler Available | On Request |

Profile Design & Applications

Adjustable Pallet Rack Uprights – Features 2-inch incremental height settings for flexible storage configurations. Teardrop Perforations – Securely locks beams in place for enhanced load-bearing stability.

Additional Machine Images

This revised version enhances clarity, eliminates redundancy, and improves readability while maintaining all technical details. Let me know if you’d like any further refinements!

Reviews

There are no reviews yet.