WF-12-36 Roof Panel Roll Former

The WF-12-36 Roof Panel Roll Forming Machine is a high-speed, high-precision production line engineered for manufacturing the WF-12-36 metal roofing profile. This panel—featuring 36’’ coverage, deep ribs, and superior strength—is widely used in commercial, industrial, and agricultural buildings.

Designed and produced by Zhongtuo Machine (ZTRFM / ZTFRM Machine), this roll forming system integrates full automation, heavy-duty components, and a stable chain-driven transmission structure to ensure long service life and consistent panel accuracy.

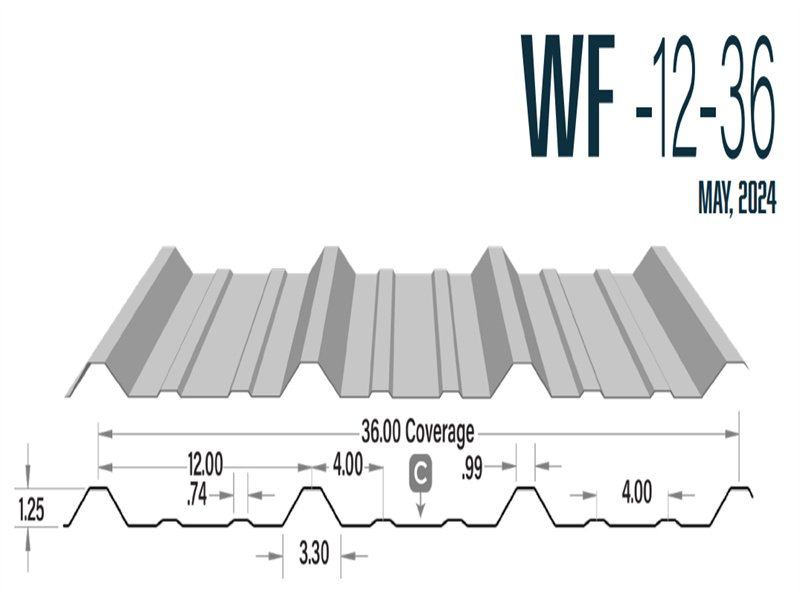

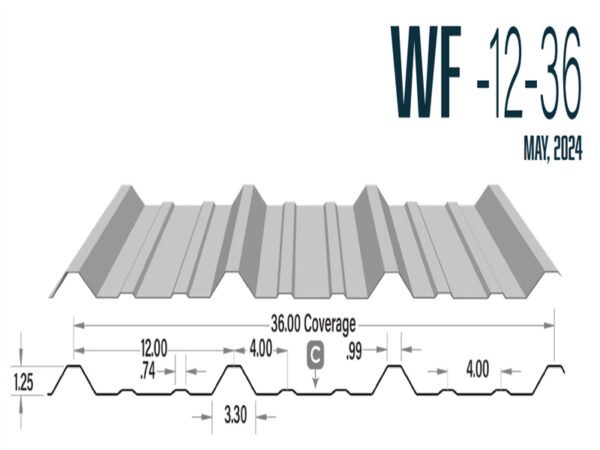

WF-12-36 Profile Drawing

The WF-12-36 panel features:

- 36” coverage width

- Rib height: 1.25 inches

- Rib spacing: 12.00” / 4.00” / 0.99” / 4.00”

- Strong structural ribs (3.30” center rib) for better load-bearing capacity

This profile is widely recognized for commercial steel buildings, barns, warehouses, and roofing projects requiring high durability.

Technical Specifications of WF-12-36 Roof Panel Roll Forming Machine

| Item | Specification |

|---|---|

| PLC Brand | Delta (Original) |

| Motor Power | 11 kW |

| Shearing | Stamping / Hydraulic |

| Automation Level | Fully Automatic |

| Damping System | Optional |

| Driving Method | By Chain |

| Stacker | Manual Type or Hydraulic Auto Stacker |

| Roller Stations | 22 Stations |

| Control System | Delta PLC Control |

| Rolling Shaft Diameter | 75 mm |

| Suitable Materials | Color steel plate, HR/CR steel, Galvanized, Pre-painted coils |

| Steel Thickness | 0.3–0.80 mm |

| Tile Type | Colored Steel / Galvanized Roof Panels |

| Highlight Features | High Speed, High Precision, Industrial-Grade Durability |

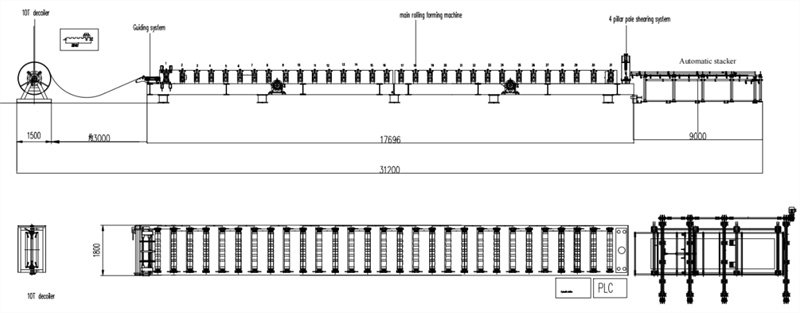

Machine Description — WF-12-36 Roof Panel Roll Former

The WF-12-36 roof panel roll forming machine is engineered for efficient, automated fabrication of roofing sheets from steel coils. It utilizes a continuous roll forming process, sending the flat strip through 22 roller stations to gradually form the precise WF-12-36 profile.

This series is widely used for commercial metal buildings due to its:

- Reliable waterproof performance

- High structural strength

- Beautiful appearance

- Low installation cost

Zhongtuo machine / ZTFRM machine guarantees consistent quality through strict manufacturing standards and fully inspected machine components.

Processing Flow

Uncoiling → Feeding → Roll Forming → Stamping/Cutting → Finished Panel Output

Advantages of WF-12-36 Roll Forming Machine

- High-speed production with stable accuracy

- Full automatic control reduces labor cost

- Designed by Zhongtuo Machine / ZTFRM Machine, a global roll forming manufacturer

- Suitable for large roofing factories, metal building suppliers, and construction companies

- Long service life with low maintenance cost

Machine Structure & Components

1. Machine Frame

- Heavy-duty 350 mm H-beam welded structure

- Reinforced 20 mm middle support plates

- Vibration aging treatment to ensure long-term stability

2. Rollers & Shafts

- High-grade 45# forged steel rollers

- 0.05 mm hard chrome plating for durability

- 75 mm heat-treated precision shafts

- 22 rolling stations ensure perfect panel shape

3. Forming Speed

- Standard speed: 0–25 m/min

- Stable chain + gear transmission system

4. Hydraulic Cutting System

- Four-pillar hydraulic cutting for stable and accurate cutting

- Blade material: GCr12 quenched steel

- Precise ±2 mm cutting tolerance

5. Control System

- Delta PLC + Delta Transducer

- Omron encoder

- Schneider low-voltage components

- Multi-language HMI (English/Chinese)

- Easily adjustable length, batch quantity, and speed

Applications of the metal roof roll forming machine

- Commercial metal roofs

- Industrial steel buildings

- Agricultural barns

- Warehouses and workshops

- Wall cladding projects

Reviews

There are no reviews yet.