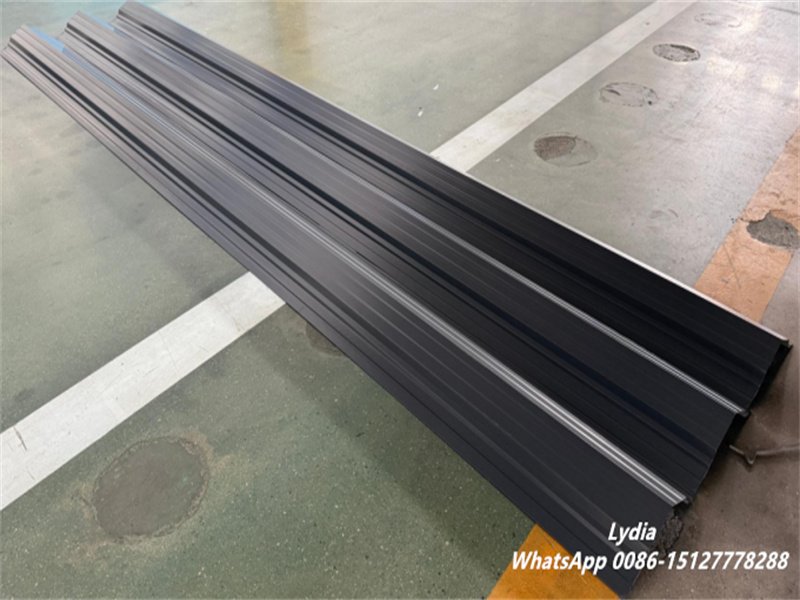

Width Adjustable Ridge Cap Roll Forming Machine for Roofing Systems

The width-adjustable ridge cap rolling forming machine is an innovative solution designed for modern metal roofing production. Unlike traditional fixed-type machines, this model allows full automatic width adjustment to produce multiple ridge cap sizes with just one line — saving both time and cost.

Why Ridge Caps Matter?

A ridge cap plays a vital role in any roofing system. It prevents water infiltration, keeps moisture away from the structure, and protects the roof from wind-driven rain and snow. As a result, it significantly extends the roof’s lifespan while maintaining its perfect appearance

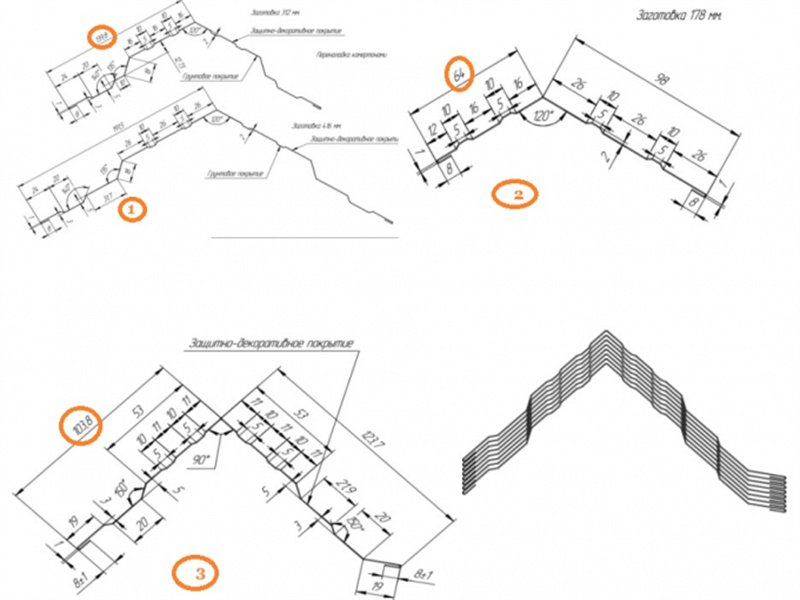

The Drawing Profile of Ridge Cap Roll Forming Machine

How the Width Adjustment Works of the metal roof ridge cap machine

The width adjustment of this ridge cap forming machine combines PLC control and servo motor precision.

For the first eight roller stations, the width can be automatically adjusted by the PLC system, ensuring smooth and accurate alignment.

- Manual Fine-Tuning for Rear Stations:

The last few roller stations are manually adjustable to ensure fine control and optimal product shape at different widths. - Rubber Rollers Protection:

Rubber rollers are added at the end section to prevent scratches and edge damage during shearing. - Segmented Roller Design:

The rollers are designed in separate segments, making it easy to adjust for larger or smaller ridge cap sizes. - Stable Forming Frame:

The molding frame ensures steady and vibration-free operation, maintaining product accuracy and consistency. - Durable Roller Material:

The rollers are made of GCr12 steel, known for its excellent hardness and wear resistance, which greatly extends the service life of the machine. - Multiple Cutting Options:

The shearing section includes interchangeable cutters designed for different ridge cap sizes, ensuring clean, accurate cuts and high production efficiency.

Key Benefits of the metal roof panel forming machine

Manual Fine-Tuning for Rear Stations

Operators can adjust the last few roller stations manually to achieve precise control and maintain the perfect ridge cap shape at any width. In addition, this manual fine-tuning gives the flexibility needed for custom sizes or special orders.

Rubber Rollers Protection

We add rubber rollers at the end of the line to prevent scratches and edge damage during the shearing process. As a result, each ridge cap keeps a smooth surface and professional finish, even at high speed.

Segmented Roller Design

Our engineers design the rollers in separate segments, allowing quick size changes between large and small ridge caps. Moreover, this modular setup simplifies maintenance and reduces downtime, improving production efficiency.

Stable Forming Frame

A reinforced molding frame keeps the machine steady and free from vibration. Consequently, it delivers consistent forming accuracy and ensures long-term stability during continuous operation.

Durable Roller Material

We use GCr12 steel for all rollers because of its excellent hardness and wear resistance. Therefore, the machine operates reliably for years, even under heavy-duty use.

Multiple Cutting Options

The shearing system includes interchangeable cutters for different ridge cap sizes. Meanwhile, the quick-change design helps operators switch sizes faster and maintain clean, precise cuts every time.

Applications of the ridge cap forming machine

In today’s competitive roofing market, versatility and efficiency are everything. The width-adjustable ridge cap rolling forming machine helps manufacturers stay ahead by offering customizable production with maximum accuracy.

If you’re looking for a smart upgrade to your roofing sheet production line, this machine is the perfect investment for future-ready manufacturing.

It’s an ideal solution for manufacturers aiming to produce high-quality, multi-size ridge caps efficiently and automatically.

Reviews

There are no reviews yet.