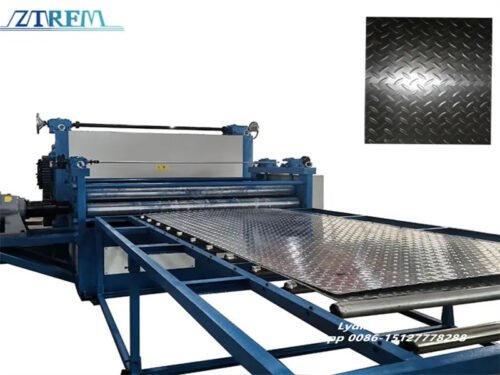

The Zhongtuo Metal Wall Cladding Panel Machine is a premium industrial machine designed for producing high-quality wall cladding panels made from aluminum or steel. It can manufacture panels up to 4 ft (about 1.2 m) in width, tailored for both exterior and interior applications.

Key Features of Wall Cladding Roll Forming Machine

Material Compatibility: Suitable for pre-painted aluminum or color-coated steel coils.

Width Flexibility: Enables automatic adjustment of panel width between 300–1200 mm via servo motor.

Length Control: Panels are cut to precise lengths using servo-controlled slicing.

Forming Speed: Reaches up to 12 m/min.

Roller Stations: Typically 14 forming rollers, but customizable per client specifications.

Roller Material: Built with Cr12MoV alloy mold steel offering high cold-forming performance.

Transmission: Driven by a reliable worm gear motor.

Cutting & Edge Bending: Utilizes hydraulic cutting integrated with edge-folding capability.

Power Requirement: Approximately 20 kW.

Production Flow

Material enters via coiled coils, then proceeds through:

uncoiling → notching → cold roll forming → automatic cutting and folding → final product output.

Factory & Support

Zhongtuo operates its own manufacturing facility, equipped with CNC machining, frame casting, parts processing, and comprehensive in-house testing. Clients are welcome to visit and witness full production and assembly processes.

They also maintain a localized after-sales network, with service centers in countries including India, Russia, Turkey, UAE, and Qatar.

Reviews

There are no reviews yet.