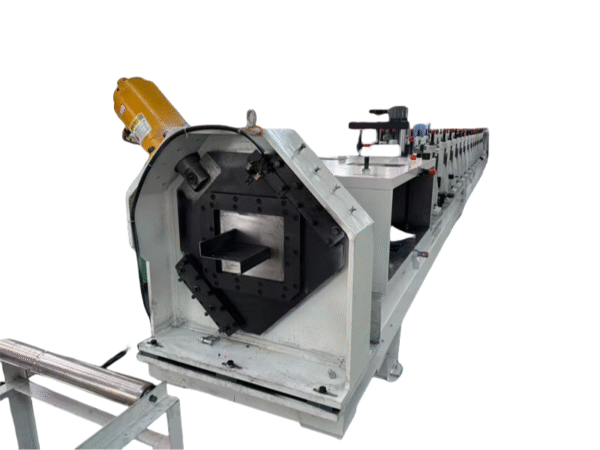

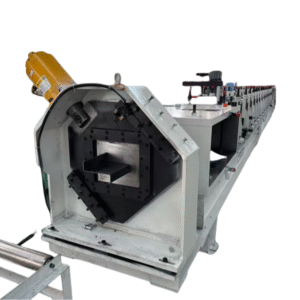

This machine is used for making the Z beam, which is used for the automatic bottom beam. The most important point of the product is keeping a high precision of hole layout when curving. Our company’s machines achieve this perfectly. And our customers are very satisfied with this machine. The whole line process flow is: Hydraulic decoiler with leveler → Hydraulic punching machine with servo feeder → Roll forming machine → Curving device → Hydraulic cutting device → Collecting table. The whole line chooses iron cast arch construction with gearbox driving, and high-strength material to make the forming mold.

High-Velocity Multi-Profile Purlin Manufacturing System

System Overview

Zhongtuo’s automated purlin production line integrates continuous forming technology with intelligent material handling to fabricate C, U, and Z structural profiles at industrial-scale throughput. The solution features synchronized non-stop cutting and automated stacking, achieving operational velocities of 35-40 meters/minute.

Operational Advantages of Z Profile Automobile Bottom Beam Roll Forming Machine

Continuous Production: Integrated fly-cut system eliminates stopping for shearing

Precision Alignment: 14-roller straightening unit (10 primary + 4 secondary)

Quick Changeover: Automated profile adjustment via PLC programming

Quality Assurance: Real-time thickness monitoring with feedback control

Safety Compliance: CE-certified guards with light curtain protection

Integrated Production Modules

| Component | Technical Specifications |

| Material Handling | 5T hydraulic decoiler with motorized coil car • Ø470-520mm mandrel • Hydraulic expansion |

| Surface Preparation | 7-roller leveling system (3 top/4 bottom + dual pinch) • Ø80/100mm hardened rollers • Adjustable 600-2200mm width |

| Pre-Forming Processing | Triple-station punching unit • Configurable single/dual hole patterns • CR12 tool steel dies (HRC 58-62) |

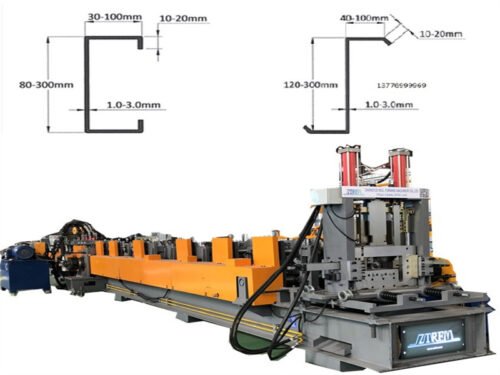

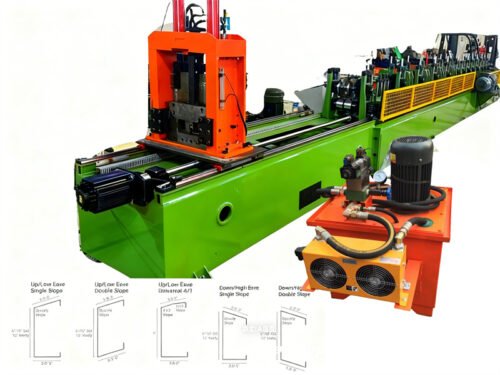

| Precision Forming | 22-stage progressive tooling • GCr15 induction-hardened rollers (HRC 60+) • 45kW main drive • 40Cr alloy shafts |

| Cutting Technology | Non-stop hydraulic shear • CR12MOV blades • Programmable length/count control (±1mm accuracy) |

| Output Handling | Automated stacker with flipping mechanism • Chain conveyor system • 12m max profile length capacity |

Technical Performance Parameters

| Category | Capabilities |

| Material Range | Hot-rolled/galvanized steel • 1.5-4.0mm thickness • 235-550MPa yield strength |

| Production Speed | 30-40 m/min (sustained) • 40% faster than conventional systems |

| Profile Dimensions | C/U/Z configurations • 1.5-12m lengths • ±0.5mm/m linear tolerance |

| Control System | Siemens PLC • 15″ HMI touchscreen • Emergency stop circuit • Bilingual interface |

| Power Requirements | 380V/50Hz 3-phase • 68kVA total capacity |

Reviews

There are no reviews yet.