Zhongtuo Cable Tray Roll Forming Machine Roll Forming Machinery

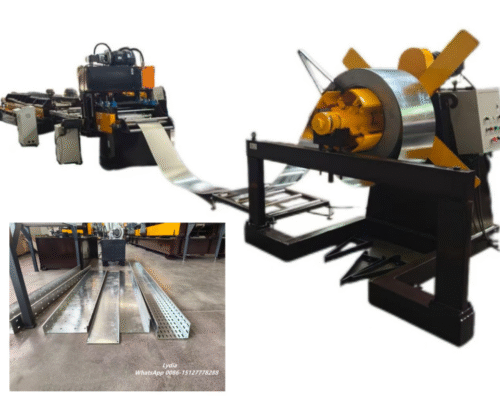

Efficient & Fully Automatic Metal Cable Tray Production Line

The Cable Tray Roll Forming Machine by Cangzhou Zhongtuo Roll Forming Machine Co., Ltd. is designed to produce high-precision galvanized steel cable trays for power distribution, industrial wiring, and infrastructure projects.

This system integrates hydraulic decoiling, leveling, servo feeding, punching, roll forming, cutting, and PLC control, ensuring continuous, efficient, and precise production.

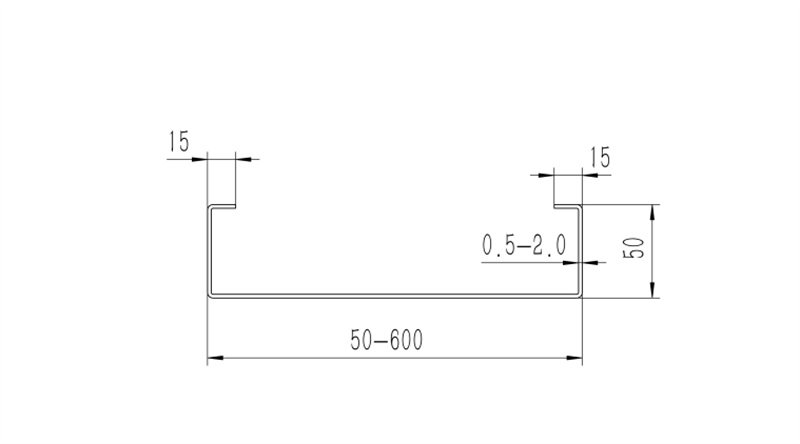

Material Width: 50–600 mm Material Height: 50 mm Thickness: 0.8–2.0 mm

Machine Configuration & Details

| Part | Name | Specification | Remarks |

|---|---|---|---|

| 1 | 5T Hydraulic Decoiler | Capacity: 5 tons; Coil inner Ø: 450–550 mm; Feeding width: 150–800 mm; Power: 5.5 kW | With pneumatic press arm |

| 2 | Leveling Machine | 7 rollers (3 upper + 4 lower); Power: 5.5 kW | Rollers: 45# steel, quenched 62–65 HRC |

| 3 | Servo Feeding Machine | Power: 2.2 kW; Length: 12 m | Multi-stage feeding for accurate punching |

| 4 | Hydraulic Punching Machine | Punching Force: 200T; Die Material: Cr12MoV | Online punching and cutting |

| 5 | Punching Dies | Cr12MoV material | Combined the mold with the cutter |

| 6 | Roll Forming Machine | Shaft: 40Cr, Φ65mm; Roller: Cr12 HRC56–58; 26 stations | Transmission: chain; Motors: 5.5 kW×3, 1.5 kW×2 |

| 7 | Shearing System | Hydraulic cutting | Integrated with punching |

| 8 | PLC Control System | PLC: Delta; Encoder: Omron; Electrical: Schneider | Touch screen; Multi-language |

| 9 | Product Collect Table | 3m × 2 sets | Adjustable width, welded steel frame |

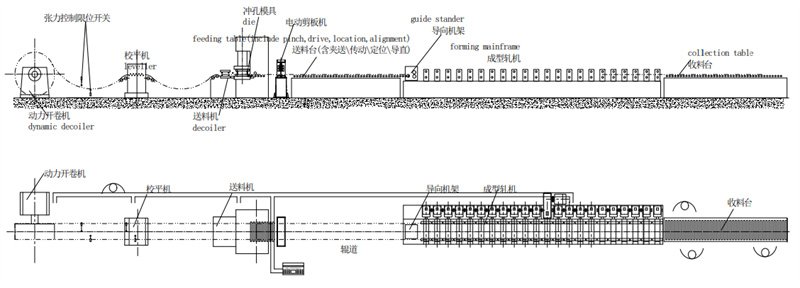

Working Flow

Decoiling → Leveling → Servo Feeding → Hydraulic Punching → Roll Forming → Cutting → Output Table

This automated flow ensures seamless operation, minimal manual interference, and high consistency across all produced trays.

Main Performance Parameters

| Parameter | Specification |

|---|---|

| Raw Material | Galvanized Steel |

| Thickness | 0.8–2.0 mm |

| Cutting Length | Adjustable |

| Forming Speed | 10–15 m/min |

| Power Supply | 380V / 50Hz / 3 Phase |

| Roller Stations | 26 |

| Total Power | Approx. 35–40 kW |

| Control System | Delta PLC + Touch Screen |

| Accuracy | ±1.0 mm |

Applications

The Zhongtuo Cable Tray Roll Forming Line is ideal for:

- Electrical cable support systems

- Industrial automation wiring

- Power plants & factories

- Commercial building infrastructure

It supports various tray sizes, hole types, and thicknesses without changing molds, offering great flexibility and production efficiency.

Why Choose Zhongtuo

Over 15 years of roll forming experience

Exported to 130+ countries, including the USA, India, Saudi Arabia, and Europe

ISO9001 & CE certified production

Expert engineering team & lifetime technical service

Zhongtuo is committed to “Quality First, Customer First, and Continuous Innovation,” delivering machines that empower your business with precision, reliability, and global competitiveness.

Reviews

There are no reviews yet.