Sigma Purlin Roll Forming Machine: Complete Guide for Efficient Steel Building Production

A sigma purlin making machine is a roll forming production line that manufactures sigma-shaped steel purlins for metal buildings and roofing systems.

Unlike traditional C or Z purlins, sigma purlins provide higher structural strength with optimized material usage.

Therefore, many manufacturers choose sigma profiles for pre-engineered steel buildings, warehouses, and low-rise constructions.

In this guide, we explain how sigma purlin machines work, their main components, production flow, machine types, and how to select the right solution for your project.

What Is a Sigma Purlin?

Sigma purlins are structural steel members installed perpendicular to roof or wall panels.

Thanks to their unique sigma-shaped cross section, they deliver:

- Higher strength-to-weight ratio

- Better resistance to bending and deflection

- Optimized steel usage with lower material cost

As a result, sigma purlins are increasingly used in steel warehouses, industrial plants, commercial buildings, and low-rise constructions.

How a Sigma Purlin Roll Forming Machine Works

The sigma purlin roll forming process follows a continuous and automated workflow.

First, the steel coil is uncoiled and guided into the machine. After flattening and alignment, the strip passes through multiple roll forming stations, where each set of rollers gradually bends the metal until the final sigma profile is achieved.

Next, optional punching units create bolt holes or slots. Finally, the finished purlins are cut to precise lengths and transferred to the exit table for stacking or automatic bundling.

Because the forming process is progressive, the machine ensures high dimensional accuracy, smooth surfaces, and consistent quality.

Main Components of a Sigma Purlin Making Machine

Each sigma purlin production line consists of several integrated systems working together:

| Section | Main Components | Function |

|---|---|---|

| Decoiling | Hydraulic or manual decoiler | Smooth coil unwinding |

| Feeding & Guiding | Feeding rollers, entry guides | Stable material transfer |

| Pre-treatment | Straightener, edge trimmer (optional) | Improves flatness and accuracy |

| Roll Forming | Roll stands, shafts, gearboxes, motors | Gradual forming of sigma profile |

| Post-forming | Punching unit, hydraulic shear | Hole punching and cut-to-length |

| Automation | PLC, servo motors, sensors | Production control and monitoring |

| Output | Run-out table, auto stacking system | Cooling, collection, bundling |

The roll forming section is the core of the machine. A higher number of forming stations ensures better profile precision and higher speed.

Sigma Purlin Production Process Flow

The full production process typically includes:

- Decoiling – Steel coil is loaded and unwound smoothly

- Feeding & Alignment – Strip is guided accurately into the line

- Pre-treatment – Straightening and trimming prepare the material

- Roll Forming – Progressive bending forms the sigma profile

- Punching – Bolt holes or slots are created if required

- Cutting – Hydraulic shear cuts purlins to set lengths

- Cooling & Stacking – Finished purlins are stabilized and bundled

Thanks to automation, the entire process runs continuously with minimal labor.

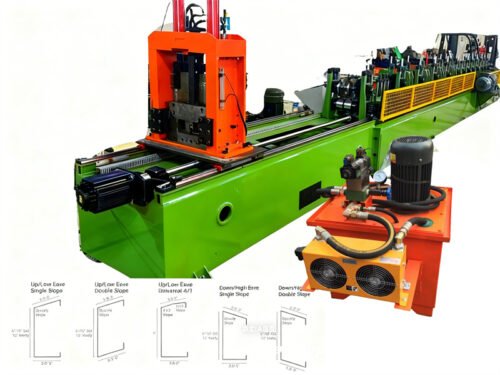

Types of Sigma Purlin Roll Forming Machines

Different production needs require different machine configurations:

| Machine Type | Application |

|---|---|

| Portable Sigma Machine | On-site roll forming for small projects |

| Manual Sigma Machine | Low-volume, budget-friendly production |

| Automatic Sigma Machine | High-speed industrial manufacturing |

| Customized Sigma Machine | Tailored profiles, sizes, and output |

Choosing the right type depends on production scale, size range, budget, and mobility requirements.

Key Design Considerations

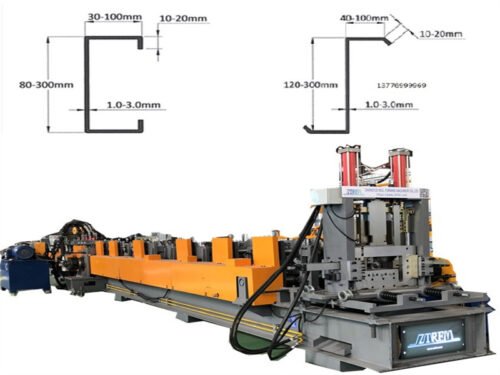

When selecting a sigma purlin roll forming machine, consider the following factors:

- Purlin dimensions and thickness range

- Steel grade and coating (GI, PPGI, high-strength steel)

- Required production speed and daily output

- Hole patterns and cutting accuracy

- Level of automation and labor availability

A professional manufacturer can customize the machine layout, roll design, and control system to match your exact requirements.

Their strength and efficiency make them a preferred choice for modern steel construction.

Why Choose ZTRFM Sigma Purlin Roll Forming Machine?

With years of experience in cold roll forming technology, we provide:

- Fully customized sigma purlin solutions

- CE & ISO certified production lines

- Stable performance and long service life

- Professional installation and after-sales support

Our machines help customers reduce material costs, increase productivity, and improve structural reliability.

Reviews

There are no reviews yet.