Product Details of C89 Light Gauge Steel House LGS Framing Roll Forming Machine for Villa

Single Profile Steel Framing Machine C89-1.6mm

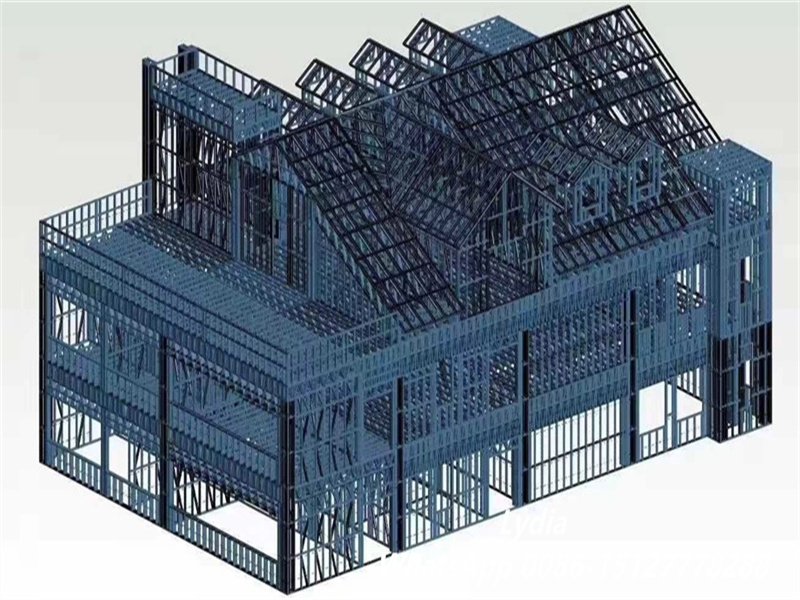

The C89 Light Gauge Steel (LGS) Framing Roll Forming Machine is a high-precision, single-profile steel frame production line designed for villa construction, residential housing, modular buildings, and light steel structure projects.

With a forming capacity of up to 1.6mm, this model provides strong structural performance while maintaining high-speed, stable, and automated production.

Material & Mechanical Performance

- Coil Material: Galvanized coil, Aluminum-zinc coil

- Yield Strength: G550 MPa high-tensile structural steel

- Forming Part Size: 5.6m × 1.1m × 1.6m

- Machine Weight: About 4.5 Tons

- Overall Dimension (with decoiler & output table):

11m × 1.35m × 1.5m

These specifications ensure the C89 machine meets strict requirements for lightweight structural housing, offering both strength and precision.

Working Flow

Decoiler → Leveling Device → Punching System → Roll Forming Machine → PLC Control System → Receiving Table

This streamlined flow ensures high accuracy in punching, forming, and cutting operations.

Why Choose Zhongtuo the C89 Light Gauge Steel Framing Machine?

High Speed & High Precision — up to 48m/min forming

Strong Steel Capacity — handles 1.6mm G550 MPa

Optimized for Villa & LGS Housing Projects

Fully Automated Punching & Cutting

Durable Rollers & Shafts for Long Machine Life

Stable Structure with Full Safety Protection

This machine is specially designed for companies producing light steel villa structures, modular homes, and prefabricated buildings.

Main Components of C89 light gauge steel roll forming machine

| Item | Description | Unit | Qty |

|---|---|---|---|

| 1 | 3 Ton Decoiler | Set | 1 |

| 2 | Levelling Device | Set | 1 |

| 3 | Punching System | Set | 1 |

| 4 | Main Roll Forming Part | Set | 1 |

| 5 | Online Printer (Double-side) | Set | 1 |

| 6 | PLC Control System | Set | 1 |

| 7 | Receiving Table | Set | 1 |

| 8 | Spare Parts | Set | 1 |

Component Description

1. Decoiler

- Type: Manual

- Capacity: 3 Tons

- Inner Diameter: 480–510 mm

- Outer Diameter: 1600 mm

- Motor Power: 2.5 kW

Stable material feeding ensures smooth production without material distortion.

2. Leveling Device

Equipped with four leveling rollers to tightly fix and flatten raw material during punching and forming, ensuring high accuracy and consistent product shape.

3. Punching System

- Material of punching dies: SKD11

- Hydraulic Motor Power: 7.5 kW

- Punching Stations: 9 functions

- Driven by servo motor

- Hole Type: Customized

- Punching Accuracy: ±0.5 mm

- Blade Material: Cr12MoV, heat-treated

This system ensures clean, high-speed punching suitable for structural framing.

4. Main Roll Forming Section

- Main Motor Type: Servo Motor

- Brand: Inovance

- Motor Power: 7.5 kW

- Forming Speed: 48 m/min

- Comprehensive Speed: 5–20 m/min

- Roller Stations: 16 groups

- Roller Material: GCr15 hardened steel

- Shaft Diameter: Ø60 mm, Material: 40Cr

- Frame Material: 45# Steel, Thickness: 20 mm

- Equipped with flare control rollers for final straightening

- Hydraulic Post Cutting System

- Cutting Material: Cr12MoV

- Hydraulic Motor Power: 7.5 kW

The forming section is designed for long-term durability with no deformation, ensuring precise and stable product output.

5. Online Printer

Two-side automatic marking system for project codes, sizes, production data, etc.

6. PLC Control System

- Functions: Control punching, length measurement, cutting, auto-counting

- The machine stops automatically during punching & cutting

- Voltage: 380V, 3-Phase, 50Hz (customizable)

Recommended Applications

- Light Gauge Steel Villas

- Prefab Houses

- Mobile Homes

- Modular Buildings

- Wall Studs & Tracks

- Floor Joists

- Partition Frames

Reviews

There are no reviews yet.