Cee & Eave Strut Roll Forming Machine High-Precision Purlin & Eave Strut Production Line

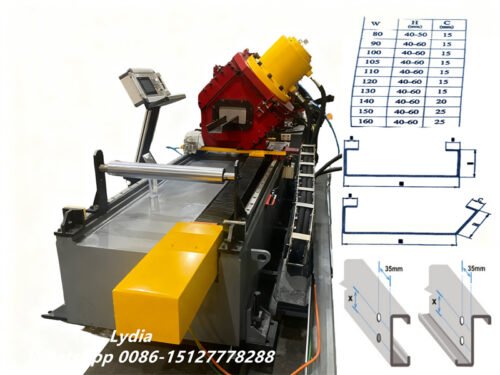

The Cee & Eave Strut Roll Forming Machine is an advanced production line designed to manufacture Cee profiles, girts, and eave struts for metal buildings, warehouses, and steel structures. With high-speed forming, precision cutting, and full automation, this machine delivers consistent quality and efficiency for modern construction needs.

Machine Description: Cee & Eave Strut Roll Former

The Cee & Eave Strut Roll Forming Machine transforms steel coils into accurately shaped C purlins, girts, and eave struts. The line feeds material continuously, forming profiles through a series of 21 precision rollers before cutting them to the required length using a hydraulic shear.

How the Machine Works

- Coil loading

- Straightening

- Roll forming through automated stations

- Punching (optional)

- Hydraulic shear cutting

- Run-out table stacking

This fully automated process allows manufacturers to produce high-strength metal building components with minimal labor.

Key Benefits of the Cee purlin roll forming machine

- ✔ High-speed forming up to 60 ft/min

- ✔ Supports multiple profile sizes (5″–12″)

- ✔ Produces Cee purlins, girts & eave struts in one line

- ✔ Delta PLC ensures reliable, stable production

- ✔ Strong frame structure supports heavy-duty operation

- ✔ Easy profile change & flexible adjustment

The machine is ideal for manufacturers supplying:

- Metal building components

- PEB structures

- Steel framing systems

- C purlins, girts, and eave struts

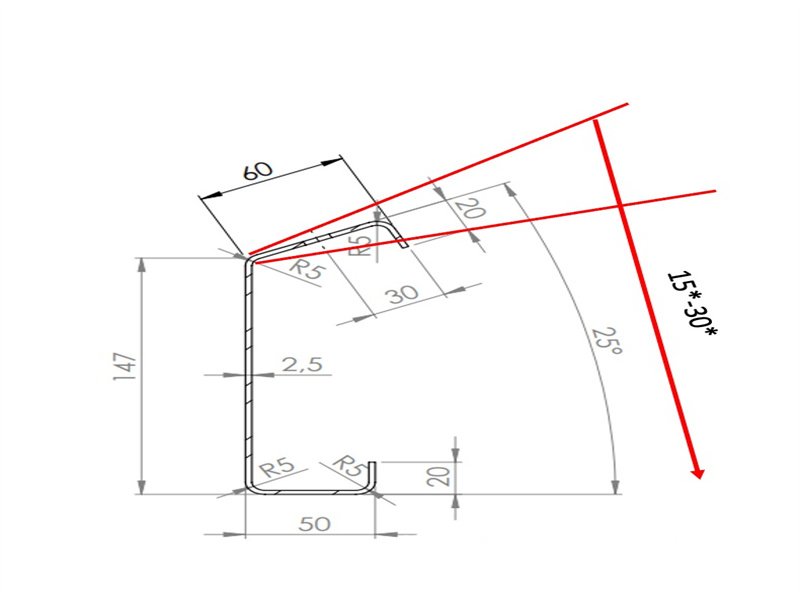

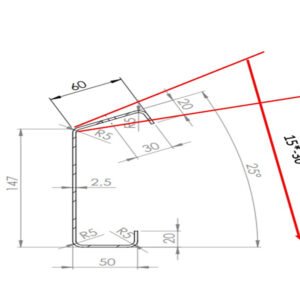

What Are Eave Struts?

Eave struts are structural components located at the junction of the roof and wall—the building’s eave line.

They support both roof and wall panels and are typically manufactured in a C-shaped profile.

When ordering eave struts, customers can specify:

- Single slope

- Double slope

- Low eave

- High eave

- Universal style

Slopes up to 4:12 are available.

These components are essential for stability in pre-engineered steel buildings and metal roofing systems.

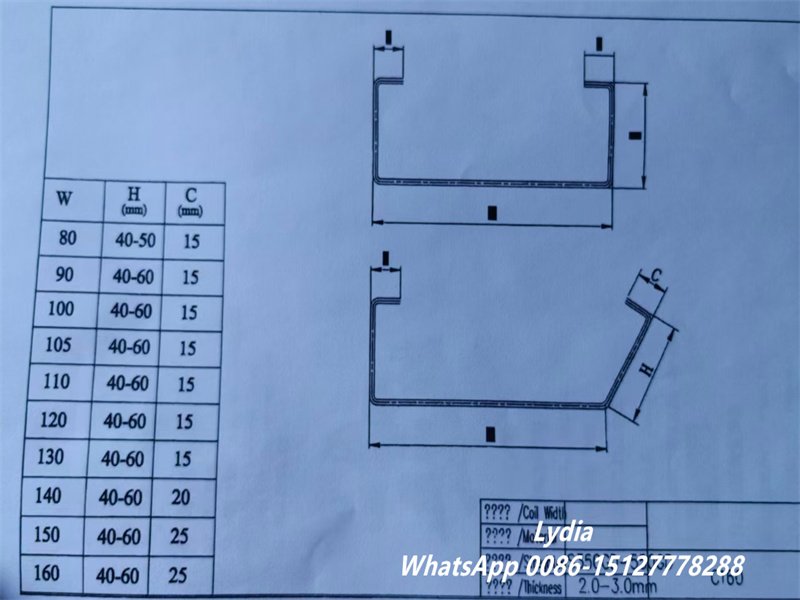

Cee & Eave Strut Roll Forming Machine Specifications

| Specification | Details |

|---|---|

| Profile | 5″ to 12″ |

| Coil Width | Variable |

| Forming Speed | 50–60 ft/min |

| Material Thickness | Variable |

| Machine Weight | 15 ton |

| Machine Footprint | 60 ft × 12 ft |

| Main Power | 32 HP – 480V – 3PH |

| Stations | 21 |

| Cutting Type | Hydraulic Shear |

| Control System | Delta PLC + Inverter |

| Safety Covers | Yes |

| Emergency Stops | Yes |

| Delivery Term | FOB Tianjin, China |

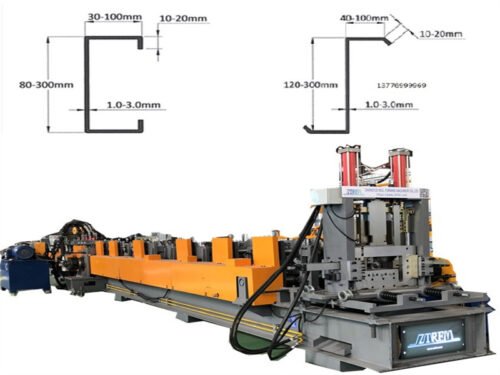

What Are Cee Profiles? (Cee Purlins & Girts)

Cee profiles—also known as C purlins or C girts—are horizontal structural members used to support roof decks and wall panels in metal buildings.

Applications of Cee Profiles

- As purlins: Placed horizontally along the roof to support metal sheeting

- As girts: Installed on walls to provide support and attachment points for cladding

Their C-shaped design provides excellent structural strength while keeping material weight low. The narrow profile makes Cee purlins ideal for tight spaces, such as areas close to eaves.

Because the center of gravity lies near the center of the section, Cee profiles sit securely on their short edge—making them easier to handle during installation. They are commonly used in:

- Carports

- Light steel structures

- Industrial buildings

- Warehouse wall/roof framing

Available Finishes of Roll Forming Machine

- Galvanized C purlins

- Red oxide-coated C purlins

Both coatings help extend the lifespan of metal buildings while reducing maintenance requirements.

Why Choose a Cee & Eave Strut Roll Forming Machine?

This equipment provides a cost-effective and highly efficient solution for producing two of the most important steel structural components—Cee profiles and eave struts. With continuous roll forming, strong profile accuracy, and automated process control, the line significantly improves production capacity and reduces downtime.

Reviews

There are no reviews yet.