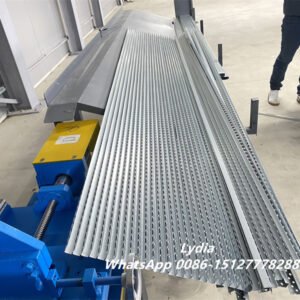

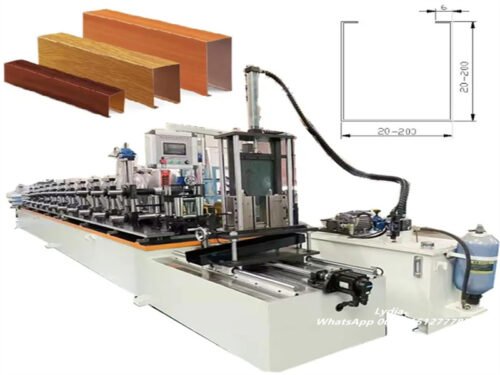

Combo Drywall Roll Forming Machine for Hat Channel, Stud & Track, Wall Angle

The Combo Drywall Roll Forming Machine is designed for manufacturers who need high output, flexible profile production, and space-saving equipment. Instead of running multiple standalone machines, this solution integrates two roll forming lines into one compact system, allowing different drywall profiles to be produced at the same time.

As a result, production efficiency increases while labor and factory space requirements decrease.

One Machine, Two Drywall Profiles

This combo roll forming machine can simultaneously manufacture two different profiles, such as:

- Metal hat channel

- Wall angle

- C stud

- U track

Moreover, operators can easily supervise both lines from one control area, which simplifies daily operation and improves workflow efficiency.

Why Choose a Combo Drywall Roll Forming Machine?

Compared with traditional single-line equipment, this machine delivers clear advantages:

- Higher productivity – two profiles produced at once

- Lower investment cost – fewer machines required

- Reduced labor – one operator can manage both lines

- Smaller footprint – ideal for workshops with limited space

Therefore, it is widely used in drywall framing systems, soffit panels, ceiling furring structures, and light steel construction projects.

Main Technical Parameters

| Item | Specification |

|---|---|

| Forming Material | GI / PPGI steel strip |

| Material Thickness | 0.3 – 0.8 mm |

| Recommended Thickness | 0.5 – 0.7 mm |

| Shaft Material | 45# steel, chrome coated |

| Shaft Diameter | 80 mm |

| Forming Speed | 25 m/min (single line) |

| Max Combo Speed | Up to 45 m/min |

| Cutting Type | Hydraulic cutting |

| Punching System | Adjustable hydraulic punching |

| Hydraulic Station Power | 5.5 kW |

| Frame Structure | 300H high-grade steel |

| Control Mode | Fully automatic |

| Voltage | 380V / 50Hz / 3 Phase |

| Application | Drywall framing, soffit panel, furring system |

This simplified table helps customers quickly understand machine capacity while reducing text repetition on the page.

Hydraulic Punching System – Flexible & Precise

The machine integrates a hydraulic punching station directly into the roll forming line.

In addition:

- Punching molds are replaceable

- Hole patterns can be customized

- All hydraulic pipes are pre-installed

Therefore, installation time is reduced and hole accuracy remains consistent during high-speed production.

Integrated Oiling System for GI Coils

When processing galvanized steel at high speed, zinc residue may stick to the roller surface.

To avoid this issue, we equip the machine with an automatic oiling system, which:

- Protects forming rollers

- Improves product surface quality

- Extends machine service life

As a result, the machine performs more reliably during long production runs.

Safety Protection for Stable Operation

For safer operation, the roll forming machine includes a full protection cover.

This design minimizes operational risks and ensures stable performance during continuous production.

Suitable for Narrow Strip Drywall Profiles

Although not all wide coil profiles support combo design, narrow strip drywall profiles are ideal for this configuration.

Therefore, metal stud, track, wall angle, and hat channel profiles can be efficiently produced with one integrated system.

Custom Design Available

Every drywall market has its own standards.

If you provide your profile drawings, our engineering team will design a custom combo roll forming machine that fits your exact production requirements.

Reviews

There are no reviews yet.