Australian Specification Shipping Container House Frame Making Machine

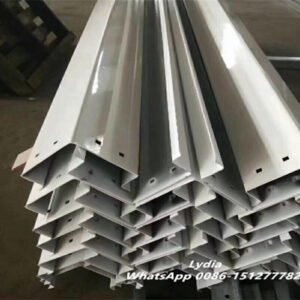

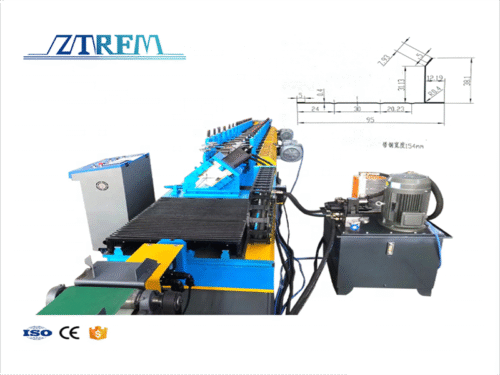

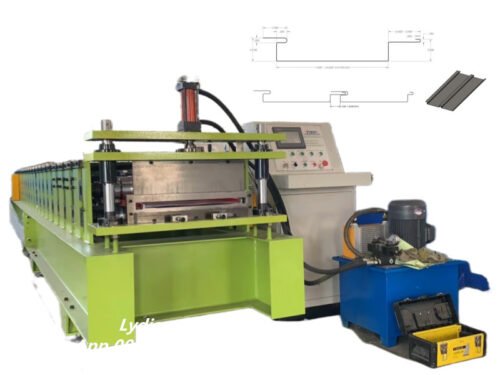

The Australian Specification Shipping Living Container House Frame Making Machine is a fully automatic roll-forming solution designed to manufacture container house frames in batches with high precision and efficiency. Built to meet Australian standards, this machine is especially suitable for producing strong, reliable pillar frames used in shipping container houses and modular living units.

Container House Frame Making Machine

Our container house frame-making machine adopts a heavy-duty roll forming structure combined with hydraulic punching and cutting. Consequently, it can handle thick galvanized steel while maintaining excellent forming accuracy and surface quality.

Key Features of the Container House Frame Making Machine

- Gearbox Transmission System

The machine uses a gearbox transmission to ensure even power distribution. As the material thickness can reach up to 4.0 mm, this design guarantees stable operation and long service life. - Hydraulic Forming and Cutting

Hydraulic molding and cutting ensure that the profile shape remains unchanged during the cutting process, resulting in clean edges and consistent dimensions. - High-Precision Rollers and Molds

All rollers and molds are precisely processed and heat-treated, ensuring accurate profiles and a smooth, professional finish. - High Production Speed

The container house frame pillar machine can reach a working speed of up to 25 meters per minute, significantly improving production efficiency. - World-Famous Electrical Components

We use internationally recognized brands for motors, PLCs, and electrical components. As a result, the machine delivers stable performance and reliable long-term operation.

Technical Parameters of the Container House Frame Making Machine

Below is a reference table of the main technical specifications:

| Item | Specification |

|---|---|

| Raw Material | Galvanized steel sheet |

| Material Thickness | 3.0 – 4.0 mm |

| Material Strength | Q235 |

| Forming Speed | 15–25 m/min |

| Roller Stations | 26 stations |

| Shaft Diameter | 95 mm (quenched & tempered) |

| Roller Material | GCr15, heat-treated and finished |

| Cutting Type | Hydraulic forming & shearing |

| Cutting Length Tolerance | ≤ ±2.0 mm |

| Control System | PLC + Touch Screen (Delta) |

| Encoder | OMRON |

Main Machine Composition

The complete container house frame making machine line includes:

- 5T × 600 mm Manual Decoiler (one load 5T, non-powered)

- Feeding and Positioning Device (with double roller tray)

- Five-Roll Leveling Device

- Main Roll Forming Host Platform (compressible & non-compressible structure)

- Wu-Roll Shaping Device

- Hydraulic Control Center (55 kW power, equipped with air-conditioning cooling)

- Hydraulic Back Punching Device (with combined punching mold)

- Hydraulic Forming Shearing Device

- Blade material: Cr12MoV, heat-treated

- Computer-Controlled Console

- Automatic length control and quantity setting

- Finished Product Run-Out Table (3 meters, non-powered)

Shipping Container Roll Forming Machine – Working Principle

A shipping container roll forming machine is used to produce container wall panels and structural components. First, large steel sheets are cut into smaller pieces. Then, the roll forming process shapes the sheets into the required profiles.

Next, the panels are corrugated. This wave-like structure significantly increases the strength of the container walls. After that, the formed panels are welded together to create full-size wall sections. Finally, square tubes are welded to the top and bottom, allowing the walls to be securely connected to the container floor and roof.

In summary, the Australian specification shipping living container house frame making machine is a powerful, efficient, and reliable solution for producing container house pillar frames and structural components. Thanks to its heavy-duty design, precise forming system, and intelligent control, it fully meets the requirements of modern container houses and modular construction projects.

If you are looking for a container house frame-making machine or a shipping container making machine that complies with Australian standards, this production line is an ideal choice for stable quality and high productivity.

What Is a Living Container House?

A living container house is a modern building system that repurposes shipping container structures into movable, eco-friendly living spaces. Thanks to their modular design, container houses can be transported and installed almost anywhere, offering flexibility and convenience for residential, commercial, and temporary accommodation projects.

Moreover, container houses can integrate:

- Solar photovoltaic panels for electricity generation

- Solar water heaters for a daily hot water supply

- Sewage treatment systems for water reuse

As a result, container houses of different sizes and layouts can be customized according to the number of occupants and functional requirements.

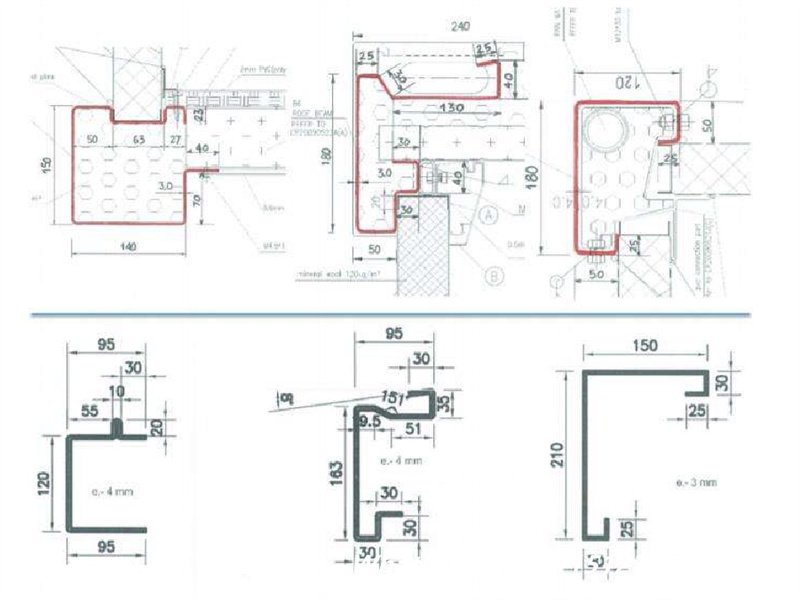

Why Focus on the Container House Pillar Frame?

In this article, we take the container house pillar frame as an example to explain how the container house frame-making machine works.

The pillar frame is one of the most critical load-bearing components of a container house. Therefore, it requires:

- High material strength

- Accurate forming dimensions

- Stable and repeatable production quality

To meet these demands, we design a dedicated container house frame-making machine with a strong structure and advanced hydraulic and control systems.

Reviews

There are no reviews yet.