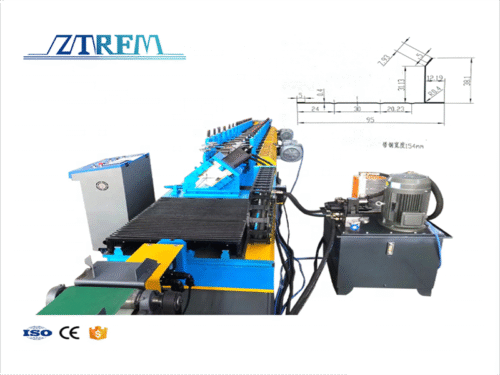

Zhongtuo TR10/TR40 Double Deck Roll Forming Machine

High Efficiency Trapezoidal Roof Sheet Making Machine

The TR10/TR40 Double Deck Roll Forming Machine is designed to manufacture two types of trapezoidal roofing sheets on a single machine frame. With a dual-layer forming structure, it allows fast profile switching without changing molds, significantly reducing downtime and improving production efficiency.

This machine is ideal for roofing sheet manufacturers, building material suppliers, and metal construction contractors looking to increase output capacity and expand product offerings.

Machine Technical Parameters of Double Layer Roll Former

| Item | Specification | Notes |

|---|---|---|

| Raw Material | Galvanized Steel / PPGI / GL | Coil-coated steel optional |

| Material Thickness | 0.3 – 0.8 mm | According to the profile type |

| Top Profile | TR10 Roof Sheet | Upper forming deck |

| Bottom Profile | TR40 Roof Sheet | Lower forming deck |

| Forming Speed | 10 – 30 m/min | Depending on the punching & PLC settings |

| Roller Stations | 16 – 26 Rows (Each Layer) | Based on the final profile complexity |

| Roller Material | GCr15 / GCr12MoV | Heat-treated, long service life |

| Shaft Diameter | 70 mm (solid shaft) | High strength and durability |

| Transmission System | Gearbox + Chain Drive | Stable and powerful |

| Cutting Type | Hydraulic Cutting | Smooth cutting, no material burr |

| Control System | PLC Automatic Control + Touch Screen | Easy and efficient operation |

| Power Requirement | 380V / 50Hz / 3Phase (Customizable) | Adjustable for any country |

| Decoiler | Manual / Hydraulic Optional | According to the production scale |

Production Advantages of Roll Former

One Machine, Two Profiles

- TR10 (Top Layer) + TR40 (Bottom Layer)

- Save workshop space, reduce equipment cost, increase product range

Fast Switching

- No need to replace forming rollers

- Switch profile via PLC control in seconds

High Production Stability

- Heavy-duty steel frame & gearbox transmission ensure stable long-term running

Uniform Profile Formation

- CNC precision-machined forming rollers guarantee consistent sheet shape and wave height

Production Line Workflow

Decoiling → Feeding → Roll Forming (Top & Bottom) → Length Measuring → Hydraulic Cutting → Finished Roofing Sheets → Stacking & Packing

Applications

This machine is widely used in:

- Industrial steel structure roofing

- Warehouse & workshop construction

- Farm buildings & shading roofs

- Residential slope roofing

- Container house and modular building supply

Why Choose This TR10/TR40 Double Deck Roll Forming Machine?

| Concern | Our Solution |

|---|---|

| Want to expand product range, but space is limited | Dual-layer design = 2 machines in 1 |

| Need to reduce production downtime | No mold change required |

| Concerned about sheet accuracy and appearance | CNC-machined GCr12MoV hardened rollers |

| Need a simple, stable, low-maintenance system | PLC + gearbox + heavy frame structure |

| Want a lifetime service guarantee | Long-term spare parts & online engineering support |

Contact Us for Price & Full Layout Design

We provide:

Factory-direct supply (no trading markup)

Installation & training support

Profile drawings customization

Shipment to 100+ countries

Send Inquiry Now:

Reply with Your Coil Width + Thickness, + Target Profile Market

We will send a quotation + machine drawings + working video within 24 hours.

Reviews

There are no reviews yet.