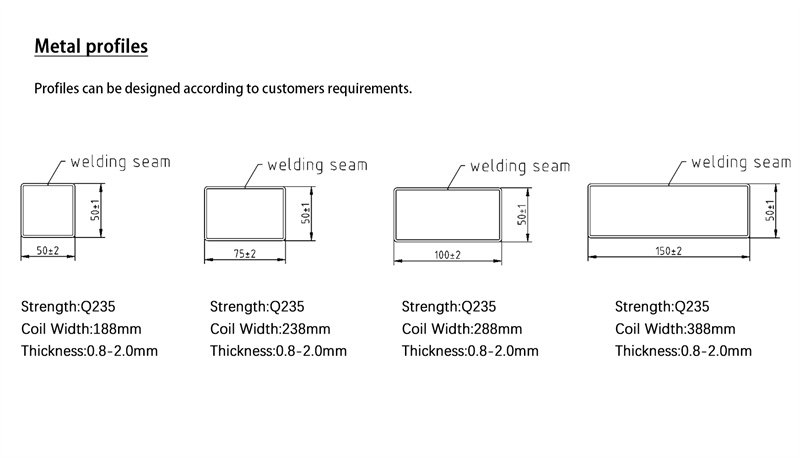

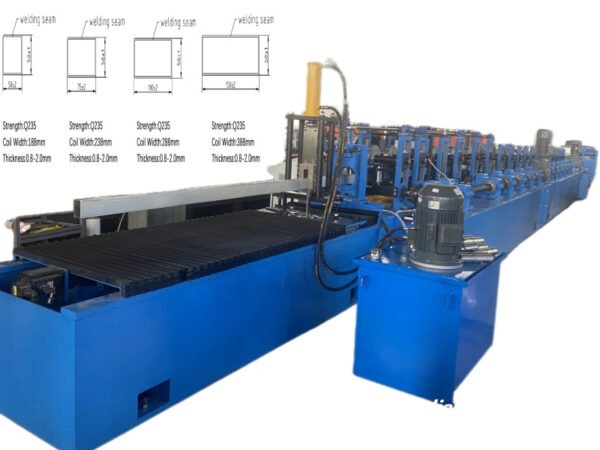

The Laser Welding Square Pipe Roll Forming Machine is a cost-effective and compact tube mill designed for producing various sizes of square and rectangular galvanized tubing. These tubes are widely used as purlins, structural supports, frames, and general construction components in metal building systems.

Compared with traditional High Frequency (HF) welding tube mills, the laser welding line offers multiple advantages:

Lower investment cost

Smaller footprint

Energy-saving operation

Simple & user-friendly control

Perfect for small factories or business startups

Why Choose Laser Welding Square Pipe Roll Forming Machine?

Laser welding technology provides:

- Higher welding precision

- Clean, smooth weld seam

- Lower heat input → minimal deformation

- More flexible for different wall thicknesses

It is especially ideal for producing medium-thickness galvanized square tubing (1.5–3.0 mm) used in steel construction projects.

We provide custom engineering solutions based on your profile drawings, tolerances, and budget.

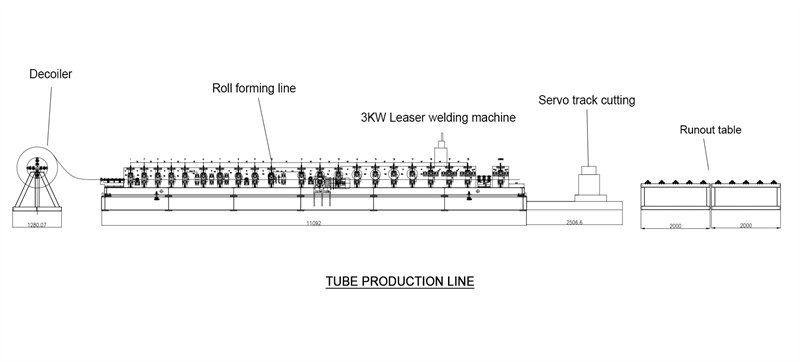

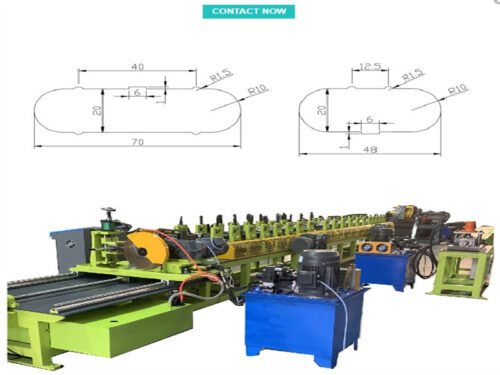

Production Flow of Laser Welding Square Pipe Line

Decoiling → Leveling → Forming → Laser Welding → Sizing → Straightening → Saw Cutting → Output Table

Smooth, continuous, and fully automatic.

Product Details of Laser Welding Tube Mill Roll Forming Machine

Raw Material

- Galvanized Steel Coil

Thickness: 1.5–3.0 mm (customizable) - Carbon Steel Coil

Yield Strength: 250–550 MPa

Technical Parameters of Galvanized Square Tubing Making Machine

| Item | Specification |

|---|---|

| Material Type | Galvanized steel / Carbon steel |

| Coil Thickness | 1.5–3.0 mm (customizable) |

| Yield Strength | 250–550 MPa |

| Decoiler | Manual / Hydraulic optional |

| Forming Stations | 16–24 |

| Driving System | Chain drive / Gearbox optional |

| Machine Frame | Wall panel / Forged iron optional |

| Forming Speed | 10–25 m/min (depending on profile) |

| Roller Material | 45# steel / Cr12Mov optional |

| Laser Power | 3 kW / 4 kW |

| Cutting System | Flying saw cutting |

| Frequency Inverter | Yaskawa / Siemens optional |

| PLC Control | Panasonic / Siemens optional |

| Power Supply | 380V 50Hz 3Ph or customized |

| Machine Color | Industrial blue or customized |

Benefits of Our Galvanized Square Tubing Making Machine

Precision Forming & Stable Laser Welding

Consistent tube dimensions with minimal distortion.

Flexible Design

We customize roller stations, welding power, and speed based on your tube sizes.

Durable & Long Service Life

High-strength steel rollers and heavy-duty frames ensure long-term plant operation.

One-to-One Engineering Support

You provide the drawing → we design the full solution → you get a ready-to-run production line.

Applications in the Construction Industry

Besides square tubing, our factory also manufactures a wide range of metal roll forming machines, including:

- Main channel roll forming machine

- C/Z purlin roll forming machine

- Drywall stud & track machine

- Top hat channel roll former

- Clip roll forming machine

- Metal deck / floor deck roll forming machine

- Roof / wall panel roll forming machine

- Corrugated sheet roll forming machine

- Ridge cap roll forming machine

- Downspout roll forming machine

Why Choose Us?

- 15+ years of roll forming experience

- Complete tube mill solutions

- Global installation & technical support

- Exported to over 90 countries

- ISO / CE / CAS certified manufacturing

We ensure you obtain stable, reliable, and high-precision steel tubing for your business.

Reviews

There are no reviews yet.