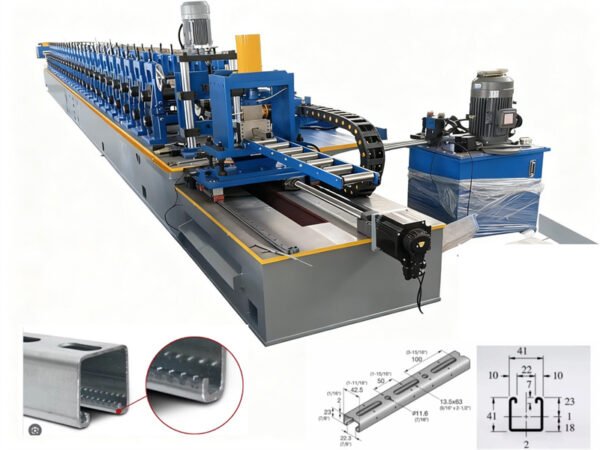

Solar Panel Bracket Roll Forming Machine

High-Efficiency Manufacturing Equipment for Photovoltaic Mounting Systems

In the construction of photovoltaic (PV) power plants, bracket systems serve as the structural link between solar modules and ground or rooftop foundations. The Solar Panel Bracket Roll Forming Machine provides high-precision and automated production of PV mounting profiles, ensuring strength, accuracy, fast installation, and long-term stability of solar power stations.

By integrating positioning accuracy, streamlined assembly, and intelligent control, this equipment accelerates PV project implementation and supports large-scale, standardized construction of solar energy plants.

Advantages for Your PV Project

- Precise and stable bracket dimensions ensure long-term system durability

- Automated processing reduces labor cost and on-site assembly time

- Supports customization for national standards and mounting design variations

- Efficient production meeting tight construction deadlines for PV projects

Technical Parameters & Solar Panel Bracket Roll Forming Machine Configuration

| Item | Specification |

|---|---|

| Formed Material | GI Sheet (Thickness: 0.8–1.8 mm) |

| Decoiler | 3 Tons Manual or Automatic Decoiler (Free Manual Type Included) |

| Roller Stations | 16 Rows (Customizable) |

| Roller Material | Gcr15 High-Strength Steel |

| Shaft Diameter | 60 mm Solid Shaft |

| Machine Body Frame | 400 H Beam Steel Structure |

| Transmission | Gear + Chain Drive |

| Machine Dimensions | 15000 × 1800 × 1600 mm (Customizable) |

| Weight | Approx. 5 Tons |

| Cutter System | Hydraulic Automatic Cutting with Cr12Mov Blades (No deformation, clean cut) |

| Main Motors | 7.5 KW × 2 Siemens Motors |

| Hydraulic Power | 15 KW |

| Voltage | 380V 50Hz 3-Phase (Adjustable per region) |

| Control System | PLC, Multi-Language Support, Touch Screen, Automatic Mode |

| Forming Speed | 25 m/min (Depends on profile size & material thickness) |

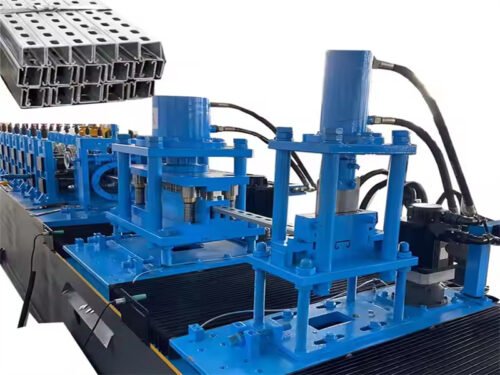

Key Technical Features

| Feature | Description |

|---|---|

| High Precision Positioning | Accurate roll forming ensures consistent profile dimensions for stable installation. |

| Automated & Intelligent Control | PLC control supports batch setting, length adjustment, quantity customization, and automatic cutting. |

| Strong Environmental Adaptability | Suitable for desert, mountains, rooftops, agricultural PV fields, water surface installations, and more. |

Applicable Scenarios

1. Centralized Photovoltaic Power Stations

For large-scale PV bases in deserts, plains, and hills, the machine supports mass production of uniform and durable support structures to ensure efficient construction and stable electricity output.

2. Distributed Solar Power Systems

Industrial plants, residential rooftops, and commercial buildings require lightweight and flexible support structures. This machine produces profiles adaptable to limited and uneven installation spaces.

3. Special Application PV Plants

Agricultural and fishing PV systems benefit from adjustable bracket heights to ensure optimal crop growth and sunlight capture. Floating PV plants require corrosion-resistant and precise mounting supports, which this machine can produce reliably.

Reviews

There are no reviews yet.