Wall Cladding Roll Forming Machine

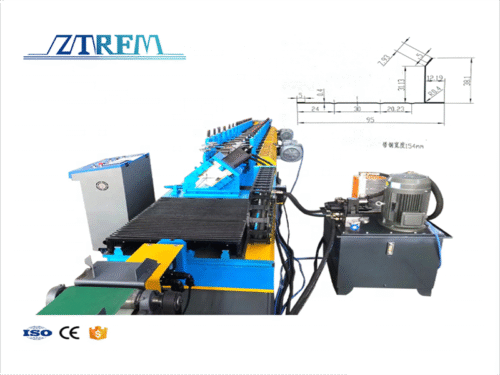

In modern lightweight steel construction, efficiency, precision, and stability are crucial for sheet metal production. The Wall Cladding Roll Forming Machine developed by Cangzhou Zhongtuo Roll Forming Machinery Co., Ltd. offers a stable, high-speed, and fully optimized solution for manufacturing thin-sheet wall cladding profiles.

This equipment is widely used in industrial workshops, warehouses, residential buildings, and architectural decoration projects.

The Wall Cladding Machine is designed for:

- Thin sheet cut-to-length production

- High speed: 25–35 m/min

- Stable forming for 24-gauge PPGI & GI material

- Accurate cutting and intelligent PLC control

The machine includes a hydraulic decoiler, a main roll former, a PLC control cabinet, a hydraulic cutting system, and 3m manual product tables, providing a complete production line for wall cladding panels.

Packing List

| No. | Name | Unit | Quantity | Remark |

|---|---|---|---|---|

| Part 1 | 3T Hydraulic Decoiler | set | 1 | Manual type optional, free choice |

| Part 2 | Main Roll Former | set | 1 | Chains drive |

| Part 3 | PLC Control Station | set | 1 | Delta brand |

| Part 4 | Hydraulic System | set | 1 | Hydraulic |

| Part 5 | Product Collect Table | set | 2 | 3m, manual type |

Production Flow

Decoiling → Feeding & Guiding → Roll Forming → Length Measuring → Hydraulic Cutting → Output Table

Technical Parameters

Product Sheet

| Series | Details | Parameter |

|---|---|---|

| Raw material | PPGI & GI | Width 152.4mm |

| Material thickness | 24 gauge | — |

| Cutting length | Adjustable | — |

Part 1: 3 Ton Hydraulic Decoiler

- Work type: Passive type, automatic expand & shrink

- Motor power: 2.2 kW with inverter control

- Hydraulic power: 1.5 kW

- Frame structure: Steel channel welded

- Loading capacity: 3 tons

- Coil width: 600 mm

- Inner diameter: 450–550 mm

- Usage: Supports coils; forklift or crane required for loading

Feeding Device

- Steel plate welded feed platform

- 1 set guiding rollers

- 2–3 guiding stripes to protect the sheet surface

- Additional bearings on both sides to protect the edges

- Roller material: Cr12MoV

- Feeding motor: 2.2 kW with inverter

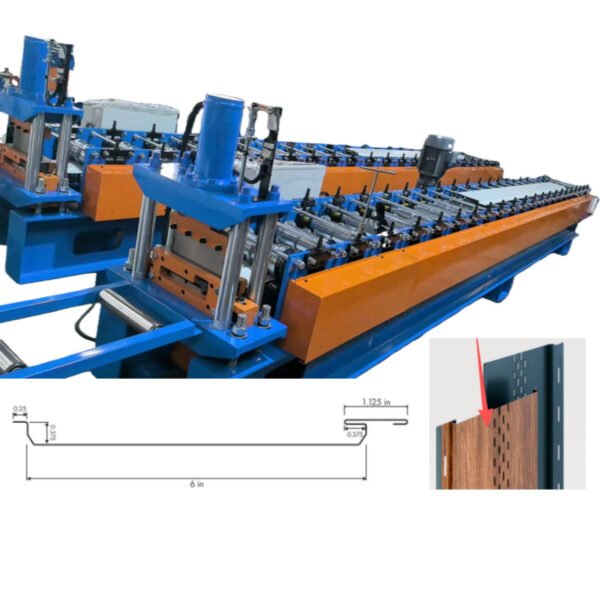

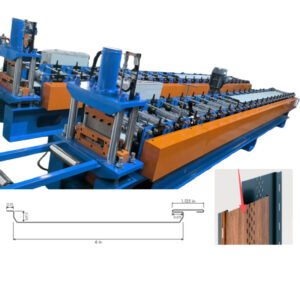

Main Roll Former

Rolling Shaft

- Material: 45# steel, chrome coated

- Type: Solid shaft

- Diameter: 60mm

- Tempering treatment for hardness & stability

Rollers

- Material: 40Cr with heat treatment (HRC48–52)

- 0.03mm hard chrome coating for corrosion resistance & smooth forming

Machine Structure

- 18 forming stations

- Speed: 0–20 m/min

- Machine frame: 350# H-beam welded

- 18mm middle plate wall, anti-rust treated

- Work power: 7.5 kW

- Transmission: Chain drive with protective cover

- Rolling spacers & steel bars: Anti-rust treated

Unique Shaft Fixing Design

Zhongtuo machine uses inset nut & cushion grooves to prevent loosening.

The longer the operation, the tighter and more stable the shafts become—greatly extending service life.

Part 3: PLC Control System

- PLC: Delta (original)

- Inverter: Delta

- Touch screen + physical buttons

- Languages: English / Chinese / Spanish

- Functions:

- Cut command

- Length preset

- Batch quantity setup

- Low-voltage parts: Schneider

- Encoder: Omron

- Aviation plug for quick installation

- Multi-orders input available

Part 4: Hydraulic Cutting System

- Work type: Hydraulic cutting

- Drive method: Pillar-type cylinder

- Motor power: 3 kW

- Blade material: GB-Cr12

- Cutting tolerance: ±1 mm per 3m

- Safety: Steady and safe cutting operation

- All tubes & wires with numbered labels for easy installation

Cooling System

Hydraulic pump station equipped with an oil cooling fan, ensuring stable operation under high-temperature environments and maintaining consistent cutting power.

Part 5: Product Table

- Length: 3 meters

- Width: 0.5 meter

- Structure: Square pipe welded

- Quantity: 2 set

Reviews

There are no reviews yet.