Premium Allclad Roofing Panel Production Line for Agricultural & Industrial Buildings

The Allclad Roof Panel Roll Forming Machine is an upgraded roofing sheet production system designed by Zhongtuo Machine (ZTFRM Machine) to meet the demands of modern construction projects. This equipment is engineered for high-speed operation, stable forming accuracy, and long-term durability—perfect for manufacturing Allclad roofing panels, AG roof panels, and agricultural metal panels.

Built with a gearbox transmission, heavy-duty rollers, and hydraulic automation, this machine ensures exceptional reliability and supports full customization for different Allclad and AG profiles.

All machines are fully assembled and commissioned at our factory in Cangzhou, Hebei, China, and include a one-year warranty covering parts and labor.

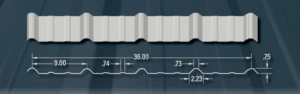

Profile Drawing

Profile key dimensions (from drawing, units: inches):

-

Overall cover width: 36.00″

-

Primary rib spacing (repeating segment): 9.00″

-

Small flange widths: approx 0.74″ and 0.73″

-

Rib/crest height: approx 0.75″

-

Valley depth / corrugation measure: approx 2.23″

Key Specifications of the Allclad Roof Panel Roll Forming Machine

| Feature | Specification |

|---|---|

| Production Speed | 0–30 m/min high-speed forming |

| Transmission | Gearbox drive for enhanced torque & precision |

| Forming Stands | 18 stations |

| Roller Type | Heavy-duty precision rollers |

| Motor System | High-power industrial motor |

| Drive Method | Chain drive |

| Cutting System | Hydraulic pre-cutter (reduces waste during coil change) |

| Supporting Equipment | Hydraulic decoiler + automatic stacker |

| Automation Level | Full automatic machine, no manual operation required |

| Customization | All profiles & sizes can be customized |

| Control System | Computer batching, PLC automation |

| Pre-Shear Function | Yes |

This advanced configuration ensures that the Allclad roll forming machine delivers consistent output, reduced material wastage, and higher manufacturing efficiency.

Machine Composition & Working Structure

1. Hydraulic Decoiler (5T / 8T / 10T Optional)

The hydraulic decoiler automatically expands its core shaft, ensuring quick and stable coil loading.

Decoiler Technical Data

- Type: Hydraulic/Passive

- Inner Diameter: 450–550 mm

- Loading Capacity: 5–10 tons

- Max Coil Width: 1450 mm

- Drive: Electric motor with frequency control

This ensures smooth material feeding, essential for high-speed forming.

2. Feeding & Guiding System

The feeding device aligns and stabilizes the metal strip before it enters the rollers.

- Adjustable hand-wheel guiding system

- Welded support platform

- High-precision bearings to protect sheet edges

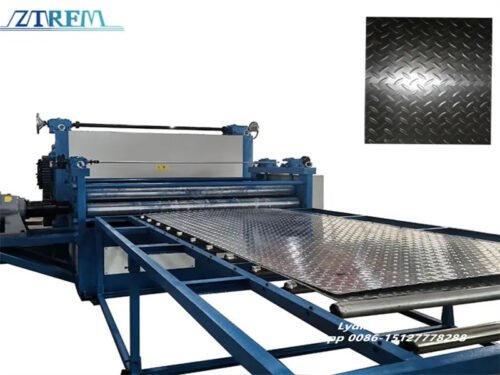

3. Main Roll Forming System (Core of the Allclad Machine)

Designed according to Allclad/AG panel specifications, the roll forming system uses premium materials and robust structure to ensure perfect shaping.

Technical Details

- Roller Material: 45# steel / GCr15 with hard chrome coating

- Roller Stations: 18 stations

- Shaft Diameter: 80 mm solid shafts

- Frame Structure: Middle plate welded design

- Machine Base: Hot-rolled H-beam with vibration aging treatment

- Transmission: Chain drive

- Work Speed: 0–15 m/min (adjustable)

- Motor Power: 5.5 kW

This heavy-duty design ensures the machine can operate continuously with high precision.

4. Hydraulic Cutting System

The hydraulic cutting device cuts the formed sheet to precise lengths with smooth edges.

Cutting Features

- Cutting Type: Hydraulic post-cutting

- Blade Material: Cr12 high-strength steel

- Power: 7.5 kW hydraulic motor

- Length Accuracy: ±2 mm

- Low noise, stable performance

- All tubes and cables are marked for easy installation

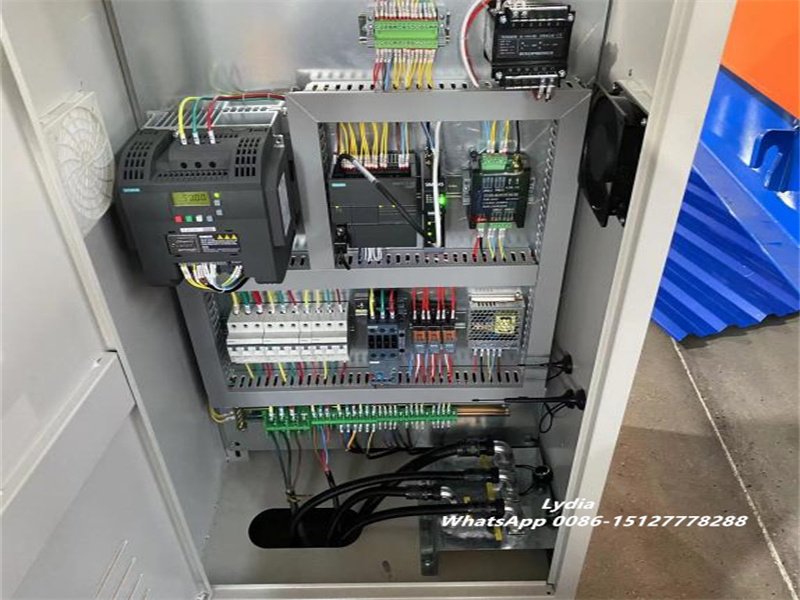

5. PLC Control System

The entire line is controlled by an intelligent PLC system to ensure consistent forming and length accuracy.

Electrical Components

- PLC & Frequency Inverter: Delta or Siemens

- Touch Screen: English/Chinese

- Low Voltage Electricals: Schneider

- Counter: Omron

- Functions:

- Cutting length control

- Batch quantity control

- Speed adjustment

- Automated start/stop sequence

This makes the Allclad Roof Panel Roll Forming Machine highly efficient and operator-friendly.

Reviews

There are no reviews yet.