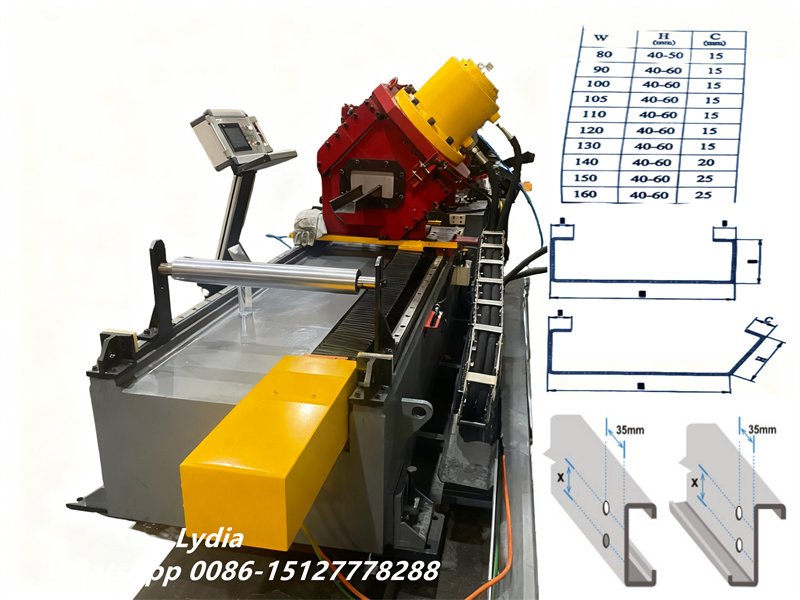

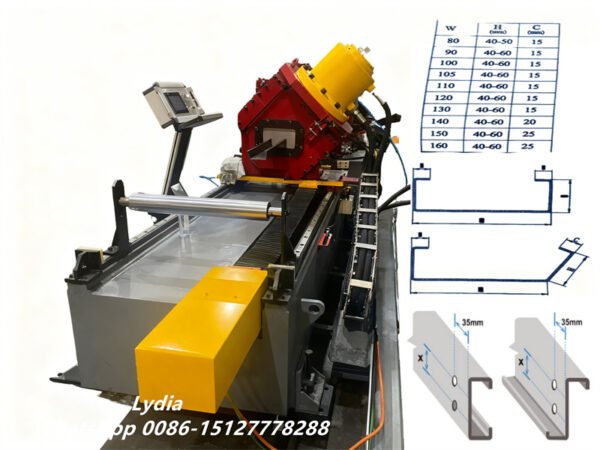

Cee, Zee & Eave Strut Roll Forming Machine for Metal Buildings High-Speed Purlin Mill Line

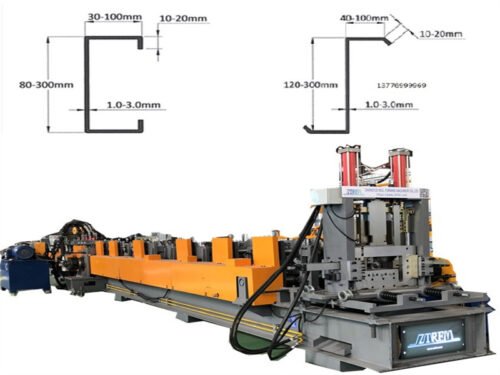

The Cee, Zee & Eave Strut Roll Forming Machine is a fully automatic production line designed for manufacturers of metal buildings, steel structure components, and industrial construction systems. With advanced forming technology and automated control, the machine delivers accurate structural profiles such as Cee purlins, Zee purlins, and eave struts—essential components used in roof framing, wall girts, and eave connections.

To support large-volume production, this forming line operates with high stability, smooth forming transitions, and continuous cutting. It greatly enhances manufacturing efficiency while ensuring consistent quality for every steel profile produced.

This roll forming system processes galvanized steel coils ranging from 1.9 to 2.6 mm thickness. After feeding and leveling, the material passes through 20 forming stations, which gradually shape the profile with excellent consistency. In addition, the hydraulic cutting unit ensures clean, accurate cuts without deforming the formed sections.

To support continuous production, the entire line is powered by high-efficiency motors and monitored through a reliable PLC + inverter control system, allowing operators to maintain optimal speed and precision during manufacturing.

Technical Specifications of the Cee & Eave Strut Roll Forming Machine

| Category | Specification |

|---|---|

| Machine Weight | Approx. 15,000 kg |

| Overall Size | 22m × 2m × 1.8m |

| Machine Color | Red (main), Yellow (warning) |

| Raw Material | Galvanized Steel Coil |

| Material Thickness | 1.9–2.6 mm |

| Coil Width | Based on product size |

| Yield Strength | 235 MPa |

| Forming Stations | 20 stations |

| Shaft Diameter | 75 mm |

| Roll Forming Speed | 10–15 m/min |

| Production Speed | 4–6 m/min |

| Roller Material | GCr15 steel (quenched) |

| Cutter Material | CR12 steel (quenched) |

| Control System | PLC + Converter |

| Main Motor Power | 18.5 kW |

| Hydraulic Motor Power | 5.5 kW |

| Voltage | Customized |

Why Manufacturers Choose This Machine

1. Consistent Profile Quality

Every forming station works together to maintain profile accuracy, which is crucial for Cee purlins and eave struts used in structural applications.

2. Durable and Stable Construction

The machine frame and components use high-grade steel, ensuring durability even under long-term, continuous operation.

3. High-Speed Production

With forming speeds reaching up to 15 m/min, this equipment significantly boosts output capacity—ideal for large-volume metal building manufacturers.

4. Excellent Raw Material Adaptability

It handles galvanized steel coils with various widths, making the production line suitable for different C-profile and eave strut designs.

5. PLC-Controlled Automation

The control system enhances precision while reducing the need for manual adjustments. Operators can set length, quantity, and cutting parameters through a simple interface.

Applications in Metal Building Construction

The Cee & Eave Strut Roll Forming Machine is widely used to produce structural components for:

- Steel warehouses

- Industrial workshops

- Pre-engineered metal buildings (PEMB)

- Agricultural facilities

- Commercial roofing systems

- Carports and shelters

Its ability to create accurate and consistent profiles ensures every steel structure achieves optimal strength and stability.

This advanced Cee and Eave Strut Roll Forming Machine provides manufacturers with a robust, high-speed, and cost-effective solution for producing essential metal building components. With strong engineering design, reliable automation, and superior forming quality, it stands out as an ideal choice for any purlin mill or metal building production facility aiming to improve efficiency and output consistency.

Reviews

There are no reviews yet.