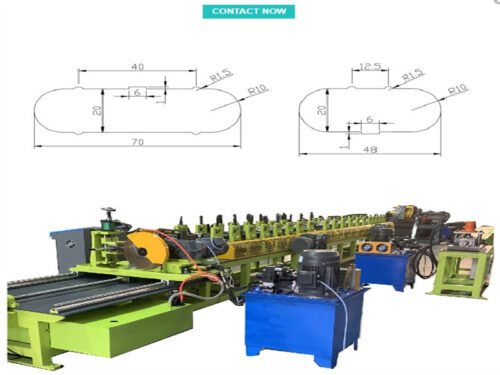

Automatic Laser Welded Tube Roll Forming Line

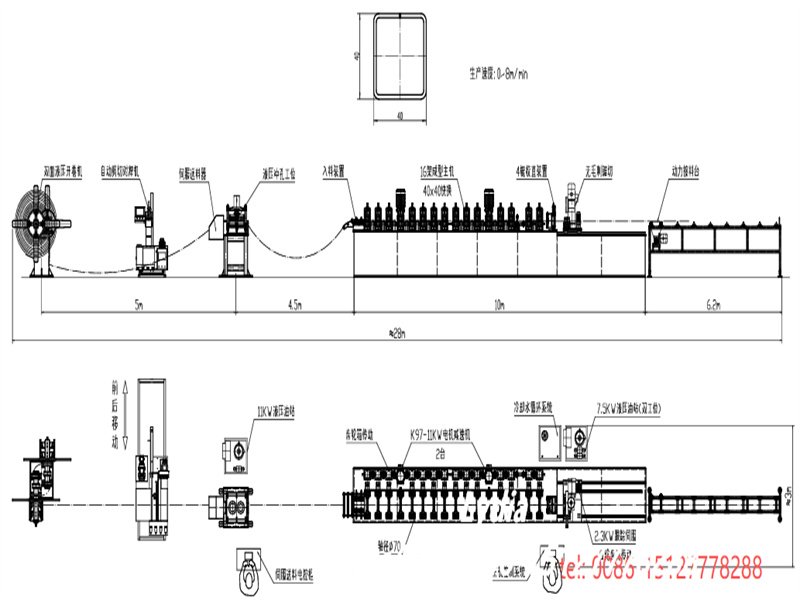

This automatic laser-welded tube roll-forming line is designed for high-precision, continuous production of welded tubes.

The line integrates hydraulic decoiling, strip end shearing & welding, punching, roll forming, laser welding, straightening, fixed-length flying saw cutting, and a run-out table, ensuring stable operation, high welding quality, and accurate cutting length.

It is suitable for steel strip processing, especially for applications requiring online laser welding, consistent tube shape, and clean weld seams.

Production Line Working Flow

Decoiling → Strip End Shearing & Welding → Punching → Roll Forming → Laser Welding → Straightening → Fixed Length Cutting → Run-out Table

Note: The working flow is for reference. Final machine layout and detailed design will be confirmed according to customer requirements.

Main Equipment Introduction

1. 3T + 3T Hydraulic Decoiler

The hydraulic decoiler supports and uncoils steel coils smoothly in a turntable mode.

It adopts passive feeding, pulled by the roll forming machine, and ensures stable strip tension during production.

Key features:

- Dual position loading capacity: 3T + 3T

- Hydraulic expansion and contraction

- Wireless remote control operation

- Heavy-duty welded frame for long-term stability

2. Strip End Shear & MIG/MAG Butt Welder

This unit is used to shear strip ends, butt-weld two coils, and level the weld seam.

It guarantees continuous strip feeding and prepares material for stable downstream processing.

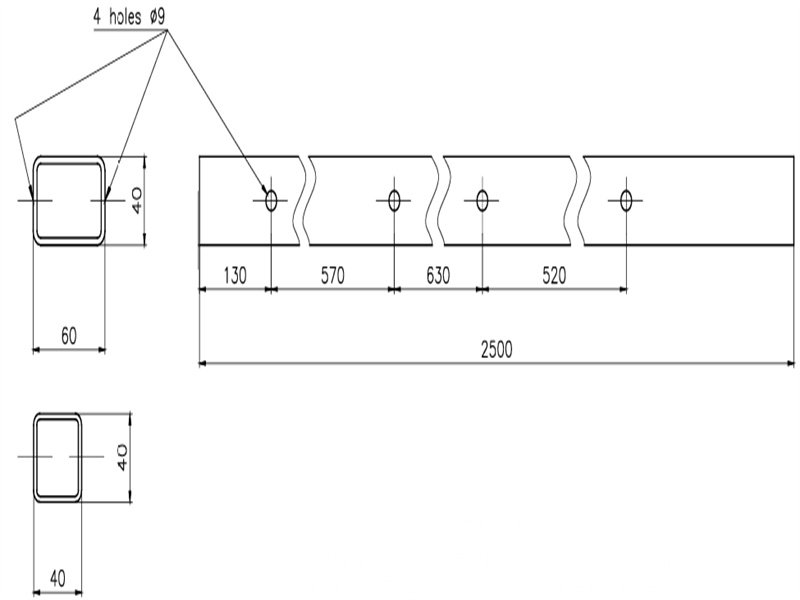

3. Punching Device

The punching system is installed inline before forming, allowing precise hole punching according to the profile design.

- Mold material: Cr12MoV

- Power: 11 kW

- High wear resistance and long mold service life

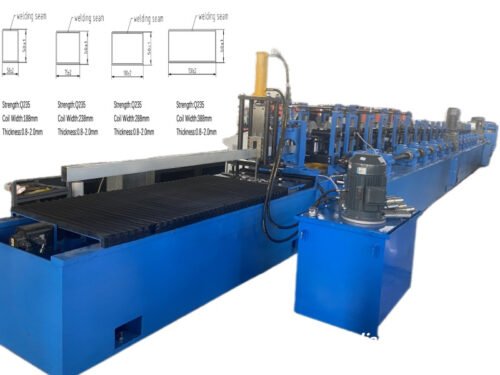

4. Main Roll Forming Machine

The roll forming section adopts a cassette model structure, allowing easier roller replacement and maintenance.

Advantages:

- 16 forming stations

- Gearbox-driven system for stable transmission

- Water cooling and emulsion piping

- Manual size adjustment with servo positioning support

5. 6 kW Online Laser Welding System

The laser welding unit welds the formed strip into a straight seam closed tube with high efficiency and excellent weld quality.

System highlights:

- Online automatic continuous welding

- Adjustable welding distance

- Flat roller pre-rounding + 6-roller extrusion device

- Outside scarfing device for smooth weld seam

- Reserved laser torch installation and grounding interface

6. Fixed Length Cutting System

The cutting section adopts a tracking flying cold saw, ensuring smooth cutting without stopping the line.

- Turk’s head 4-roll straightener for dimensional accuracy

- Servo-controlled flying saw

- Suitable for long and short length cutting

- High cutting precision and stable operation

7. Run-out Table

The finished tube is transferred smoothly to the receiving table for collection and stacking.

8. Hydraulic Station

Independent hydraulic station supplies power for:

- Flying saw cutting

- Line hydraulic actions

9. PLC Control System

The entire line is controlled by a Siemens PLC system, supporting automatic length and quantity control.

- Touch screen + button operation

- English / Chinese language interface (customizable)

- Stable electrical components from Siemens & Schneider

Main Technical Parameters (Overview Table)

| Item | Specification |

|---|---|

| Decoiler Capacity | 3T + 3T |

| Uncoiling Width | Max. 500 mm |

| Roll Forming Stations | 16 rows |

| Roller Material | GCr12MoV |

| Shaft Diameter | Φ70 mm |

| Forming Speed | 5 m/min |

| Main Motor Power | 11 kW + 11 kW |

| Punching Power | 11 kW |

| Laser Welding Power | 6 kW |

| Welding Method | Online automatic continuous welding |

| Cutting Length | 2000 – 6000 mm |

| Length Accuracy | ±1.0 mm |

| Cutting Method | Tracking flying cold saw |

| Cutting Motor Power | 7.5 kW |

| PLC / Inverter / HMI | Siemens |

| Low Voltage Components | Schneider |

Advantages of This Production Line

- High automation: Continuous production from decoiling to finished tube

- Stable welding quality: Online laser welding with extrusion and scarfing

- Precise cutting: Servo-controlled flying saw, no line stop

- Industrial-grade configuration: Siemens PLC, Schneider electricals

- Flexible customization: Line layout, tube size, and process adjustable

Reviews

There are no reviews yet.