PBR Roof Panel Roll Forming Machine for the U.S. Market

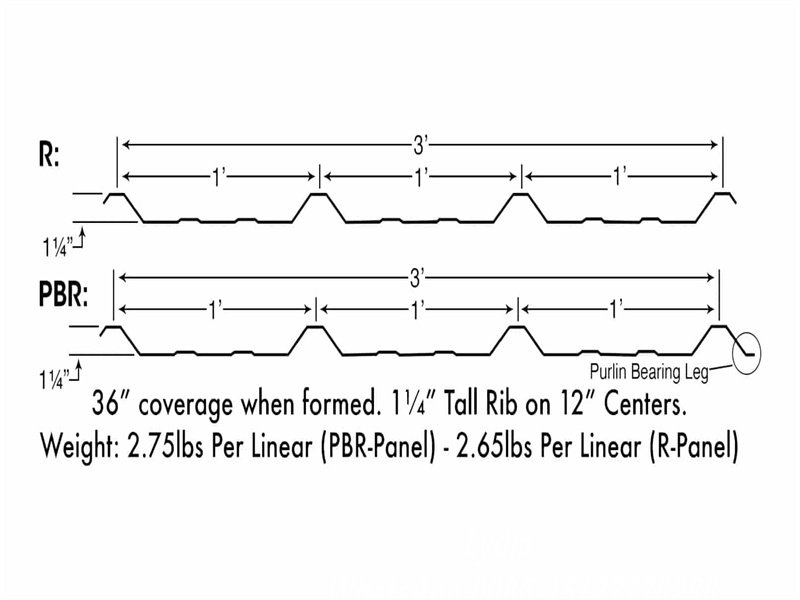

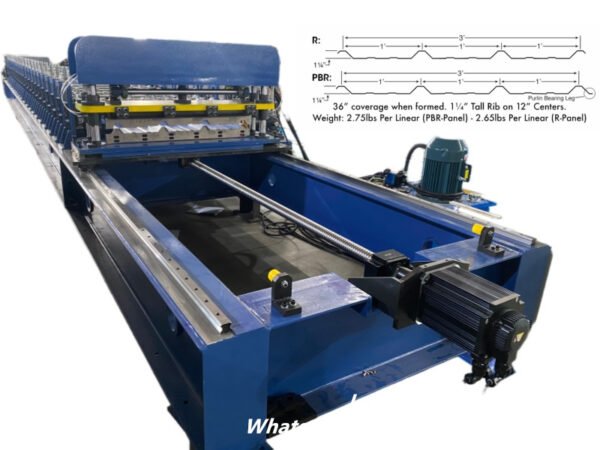

The PBR Roof Panel Roll Forming Machine is designed for manufacturers serving the U.S. metal roofing market, where durability, accuracy, and production efficiency are essential. This machine produces 36-inch coverage PBR & R panels widely used in commercial, industrial, agricultural, and steel structure buildings across North America.

Unlike standard roofing profiles, PBR panels feature a purlin bearing rib, which improves panel alignment and enhances fastener engagement. As a result, contractors achieve stronger roof systems with faster installation times.

Why Choose This PBR Roll Forming Machine

First, the machine features a heavy-duty roll-forming structure to ensure stable operation during long production runs. Next, the PLC-controlled system allows operators to accurately set panel length and batch quantity. Finally, the hydraulic cutting system delivers clean, burr-free cuts, reducing material waste and rework.

In addition, the machine supports custom panel lengths and profile requirements, making it suitable for both standard PBR roofing and wall panel applications.

Applications of the PBR panel machine

Because of its strong rib profile and consistent forming accuracy, panels produced by this machine are commonly used for:

- Metal roofing systems

- Wall cladding systems

- Fascias and soffits

- Commercial and industrial buildings

- Agricultural and storage facilities

Technical Specifications of the PBR Panel Machine

| Category | Specification |

|---|---|

| Panel Type | PBR / R Roof Panel |

| Coverage Width | 36 inches |

| Rib Height | 1 1/4 inches |

| Rib Spacing | 12 inches (center to center) |

| Material Thickness | 26 gauge (standard) |

| Forming Stations | 18–20 stands |

| Shaft Diameter | 75 mm |

| Roller Material | 45# steel, heat-treated, hard chrome-coated |

| Forming Speed | 10–15 m/min |

| Drive System | Heavy-duty chain drive |

| Cutting Type | Hydraulic stop cutting (pre-shear optional) |

| Cutting Blade | Cr12, quenched 58–62 HRC |

| Length Accuracy | ±2 mm per 10 m |

| Control System | PLC with touch screen (inch readout) |

| Power Supply | 380V / 50Hz / 3 Phase (customizable for U.S.) |

| Machine Size | Approx. 40 ft × 5 ft |

Production Workflow

To ensure smooth and efficient production, the machine follows a proven roll forming process:

Manual Decoiler → Feeding → Roll Forming → Hydraulic Cutting → Output Table

During operation, the decoiler feeds metal coils steadily into the forming section. Then, precision rollers gradually shape the PBR profile. After forming, the hydraulic cutter automatically cuts panels to the preset length.

Quality, Assembly & Warranty

All machines are fully assembled and tested before delivery to ensure stable performance. Moreover, each production line is manufactured according to customer-specific panel profiles and output requirements.

- Assembly Location: Hebei, China

- Warranty: 1 year for parts and labor

This PBR Roof Panel Roll Forming Machine provides a dependable and scalable solution for U.S. manufacturers producing commercial and industrial metal roofing panels. By combining robust mechanical design with precise control and flexible customization, the machine supports consistent panel quality while helping reduce production costs and downtime.

Reviews

There are no reviews yet.