Press & Punching Systems in Roll Forming Machines: A Practical Overview

In modern metal fabrication, press and punching systems play an essential role in improving both efficiency and product accuracy. In particular, when manufacturers integrate a punching system into a roll forming machine, they can produce holes, slots, and notches during continuous production rather than through secondary processing.

As a result, roll forming lines equipped with press punching units deliver higher productivity, better consistency, and lower labor costs.

What Is Press Punching in a Roll Forming Line?

Roll forming is a continuous metal shaping process that bends flat coils into a defined profile through multiple forming stations. At the same time, press punching machines work in line to add functional features to the sheet metal.

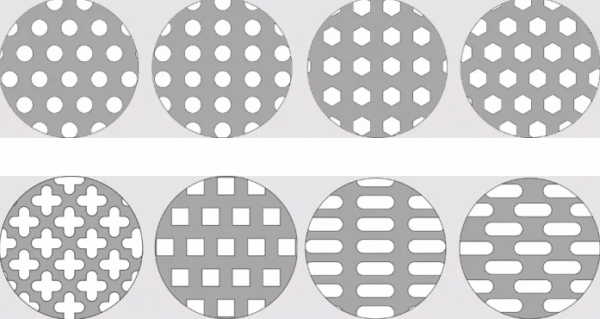

Specifically, press punching systems can perform:

- Hole punching

- Slotting

- Notching

- Cutting to length

Because these operations run in line, manufacturers avoid stopping the production line. Therefore, they maintain stable output while ensuring precise feature placement.

Pre-Punch vs Post-Punch in Roll Forming Machines

When designing a roll forming line, manufacturers usually choose between pre-punching and post-punching. Each solution serves a different production goal.

Pre-Punch Roll Forming Machine

Location:

Between the decoiler and the forming stations.

Function:

The system punches holes or slots into the flat strip before roll forming begins.

Advantages:

First, pre-punching provides excellent control over hole position and spacing.

Second, it produces highly uniform hole patterns across long production runs.

Moreover, tool design remains simpler because the material stays flat during punching.

Therefore, pre-punch systems work best for standardized products with fixed hole layouts.

Common Applications:

- Light-gauge steel framing

- C/Z purlins

- Cable trays

- Structural profiles with repetitive punching patterns

Post-Punch Roll Forming Machine

Location:

At the exit side of the roll forming machine.

Function:

The system punches or cuts features after the profile is fully formed.

Advantages:

Most importantly, post-punching aligns holes precisely with the final profile shape.

Additionally, it supports complex or asymmetrical sections.

As a result, manufacturers achieve better accuracy for custom-designed products.

Typical Applications:

- Architectural profiles

- Structural steel sections

- Custom roll-formed components

In many advanced roll forming lines, manufacturers combine both pre-punch and post-punch systems to meet complex design requirements.

Hydraulic vs Mechanical Presses in Roll Forming Machines

Press punching systems generally rely on either hydraulic presses or mechanical presses. Although both systems perform punching operations, they differ significantly in speed, flexibility, and control.

Hydraulic Presses in Roll Forming Lines

Working Principle:

Hydraulic presses use oil-driven cylinders to apply controlled force to the material.

Key Advantages:

- First, PLC-controlled operation ensures high punching accuracy.

- Next, adjustable stroke and pressure allow flexible production.

- Furthermore, hydraulic systems apply constant force throughout the stroke.

- Finally, they operate with lower noise levels.

Therefore, hydraulic presses suit thick materials, complex hole patterns, and customized roll-formed profiles.

Limitations:

However, hydraulic presses operate at slower speeds.

In addition, they require higher investment and maintenance costs.

Mechanical Presses in Roll Forming Lines

Working Principle:

Mechanical presses use flywheels, gears, and crank mechanisms to generate force.

Advantages:

- Most importantly, mechanical presses deliver high-speed punching.

- Additionally, they consume less energy during mass production.

- As a result, operating and maintenance costs remain lower.

Types:

- Full-revolution presses

- Part-revolution presses for improved control and safety

Limitations:

Nevertheless, mechanical presses offer limited flexibility.

Moreover, force applies mainly at peak points rather than uniformly.

How to Choose the Right Press & Punching System

To select the most suitable punching solution, manufacturers should evaluate:

- Material thickness and grade

- Required punching accuracy

- Line speed and output demand

- Product complexity

- Budget and long-term operating costs

For example, when customers use reliable brands such as Zhongtuo press machines, they benefit from stable performance, long service life, and consistent punching quality. Consequently, the roll forming line achieves better reliability and lower downtime.

In summary, an integrated press and punching system in a roll forming machine significantly enhances production efficiency and product functionality. Whether manufacturers choose pre-punch or post-punch configurations, hydraulic or mechanical presses, the right solution ensures accurate punching, clean cuts, and stable inline operation.

Ultimately, by selecting the correct punching system, roll forming manufacturers improve output quality, reduce secondary processing, and strengthen their competitiveness in global markets.

Reviews

There are no reviews yet.