Steel Coil Edge Protector Ring Making Machine

ID & OD Metal Edge Protection Forming Line

Steel coils require reliable protection during transportation and storage to prevent damage at their inner and outer edges. Our Steel Coil Edge Protector Ring Making Machine is designed to produce both Inner Diameter (ID) Protector Rings and Outer Diameter (OD) Protector Rings, ensuring the coil edges remain safe from deformation, friction, or collision.

This production line integrates uncoiling, punching, bending, roll forming, rib pressing, and hydraulic cutting in a continuous process. It guarantees stable performance, consistent forming accuracy, and high production efficiency for coil packaging manufacturers and steel processing centers.

Machine Capabilities

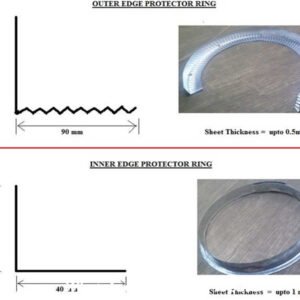

ID Protector Ring Forming

- Suitable ID Diameters: 406mm / 508mm / 610mm / 760mm (custom sizes optional)

- Material Thickness: 0.7–2.0mm

- Leg Sizes: 40mm / 110mm (adjustable)

- Designed for tight coil inner edge protection

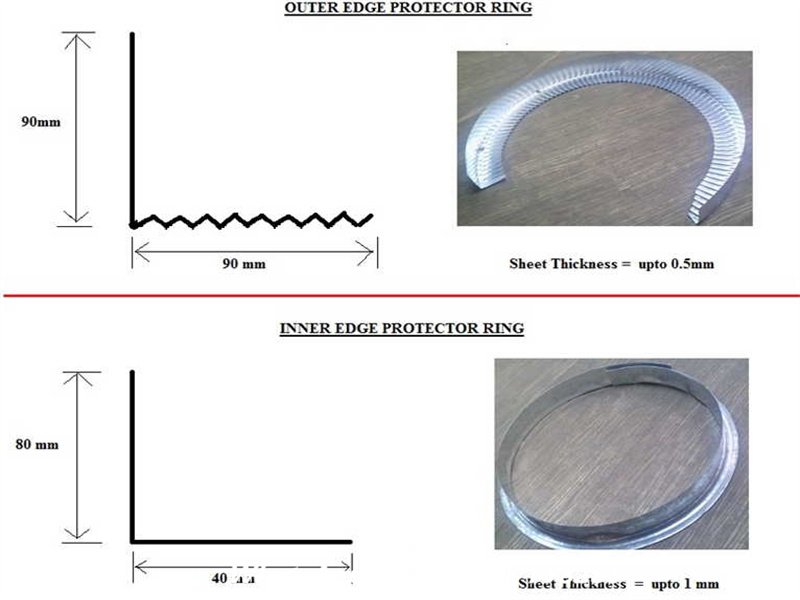

OD Protector Ring Forming

- Diameter Range: 700mm – 2000mm

- Material: CR soft steel / GI soft steel

- Standard Leg Design: 80mm corrugated leg + 120mm straight leg

- Thickness Range: 0.7–1.2mm (2.0–3.0mm optional for heavy duty protection)

Punching Function (Optional for OD Rings)

- Hole Diameter: 10mm

- Hole Spacing: 100–350mm adjustable

- Continuous punching during operation, no stop required

Technical Features & Advantages

| Feature | Advantage |

|---|---|

| One-Line Dual Mode | Switch between ID ring and OD ring via control system button |

| Continuous Punching & Cutting | No stop production → Higher efficiency |

| Flexible Strip Width Design | Strip width up to 180mm, adjustable edge width 10–20mm |

| Reinforcing Rib Unit | Enhances strength on the wide side of OD protector |

| Frequency Conversion Motor System | Smooth speed control + energy saving |

| PLC Touch-Screen Operation | Easy configuration for different ring sizes and specs |

Main Components Overview

- Hydraulic Uncoiler

- Hydraulic expansion shaft

- Max coil weight: 2200kg

- Coil ID: 508mm

- Continuous Hydraulic Punching Station

- High-precision online punching

- Handles strip up to 1.5mm thickness

- 90° Bending Unit

- Adjustable rollers for angle accuracy

- Frequency-controlled speed drive

- Reinforcement Rib Pressing Module

- Rib width: 9mm

- Rib center spacing: 40mm

- Hydraulic Flying Shear

- Continuous cut-to-length

- Max thickness: 1.5mm

- ID Protector Forming Section

- OD Protector Forming Section

- Dual Hydraulic Power Stations

- PLC + Touch Screen Electric Control System

Applications

- Steel Coil Packaging

- Aluminum Coil Packaging

- Copper Strip Coil Transportation

- Steel Service Centers

- Coil Storage & Logistic Warehouses

Request a Quote

Provide your required:

- Ring Size (ID / OD)

- Material Thickness

- Production Speed Preference

→ We will offer full technical proposal + machine configuration + quotation

Reviews

There are no reviews yet.