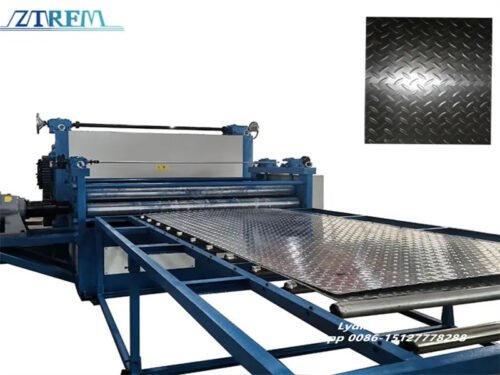

AG Panel Roll Forming Machine for Metal Roofing Production

An AG Panel Roll Forming Machine is a professional production solution designed to continuously transform flat metal coils into durable, low-rib AG panels. These panels are widely used in agricultural buildings, residential roofing, post-frame structures, and light commercial projects, where cost efficiency and long service life are essential.

By combining precision engineering with stable automation, this machine enables manufacturers to produce consistent, high-quality AG panels at scale while maintaining excellent material utilization.

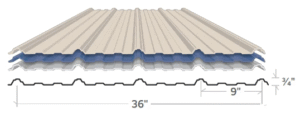

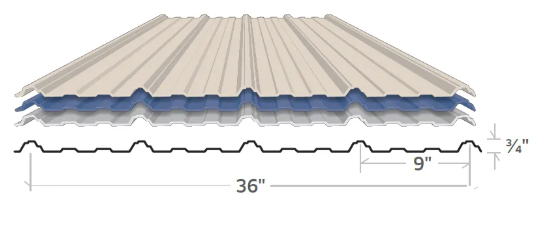

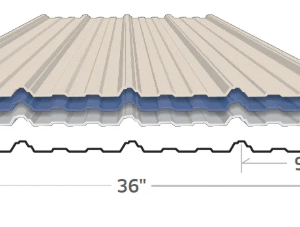

What Is an AG Panel?

AG panels are low-profile, through-fastener metal roof and wall panels known for their strength, affordability, and versatility. Compared with deeper rib panels, AG panels provide a clean appearance while remaining easy to install and transport.

As a result, AG panels have become a preferred choice for:

- Agricultural buildings and barns

- Portable and modular structures

- Warehouses and workshops

- Residential and commercial roofing systems

Manufactured from 0.3–0.8 mm steel or aluminum, AG panels deliver reliable performance even in demanding environments.

Why Choose an AG Panel Roll Forming Machine?

To meet growing demand, manufacturers need a machine that balances speed, accuracy, and flexibility. This AG panel roll forming machine is engineered to do exactly that.

First, it ensures stable forming accuracy, even at higher production speeds.

Next, it supports multiple material types, including PPGI, GI, Galvalume, stainless steel, and aluminum.

Finally, its modular configuration allows customers to upgrade components based on production needs.

Consequently, the machine suits both startups and established metal roofing manufacturers.

Main Components of the AG Panel Roll Forming Line

Each system integrates carefully selected components to ensure smooth and reliable operation:

- 5-Ton Uncoiler (Manual or Automatic)

Feeds metal coils steadily into the line, reducing tension and material deviation. - Feeding & Guiding System

Keeps the strip aligned, which directly improves panel straightness and profile consistency. - Optional Pre-Shearing Unit

Trims the coil head cleanly before forming, helping minimize scrap. - Roll Forming Section

Heavy-duty forming stands shape the metal gradually, protecting surface coatings and rib accuracy. - Cutting System (Hydraulic or Electric)

Cuts panels to precise lengths. Hydraulic cutting handles thicker materials, while electric cutting improves speed for light gauges. - PLC Control System (HMI)

Allows operators to set lengths, quantities, and production speed with minimal training. - Hydraulic Station

Powers cutting and auxiliary actions smoothly and consistently. - Panel Collection System

Supports either a manual run-out table or an automatic stacker for efficient handling.

Together, these components create a stable workflow from coil loading to finished panel stacking.

AG Panel Roll Forming Machine – Technical Parameters

| Item | Specification |

|---|---|

| Working Process | Uncoiling → Feeding & Guiding → Roll Forming → Cutting → Collecting |

| Uncoiler Capacity | 5 Tons |

| Coil Thickness | 0.3 – 0.8 mm |

| Coil Material | PPGI, GI, Galvalume, SS, Aluminum |

| Roller Material | 40Cr, Hard-Chromed |

| Forming Stands | 18 Stations |

| Shaft Material | 42Cr, Ø75 mm |

| Main Motor Power | 7.5 kW |

| Hydraulic Cutting Power | 4 kW |

| Transmission System | Chain & Gear |

| Control System | Siemens PLC |

| Encoder | Omron |

| Production Speed | 15–20 m/min |

A Smart Investment for Metal Roofing Manufacturers

For manufacturers targeting the agricultural and light construction markets, this AG panel roll forming machine offers a strong competitive edge. It combines stable output, flexible configuration, and long-term reliability, helping businesses scale production without sacrificing quality.

If you plan to expand your metal roofing line or upgrade existing equipment, this machine provides a proven and future-ready solution.

👉 Contact our technical team today for a customized quotation or to arrange a factory visit.

Reviews

There are no reviews yet.